Tech to Tech

- Subject: Providing extraordinary customer service

- Essential Reading: Shop Owner, Center Manager

- Author: Brian Manley

As an automotive-service professional, what are the extra little things you do that would distinguish your shop as extraordinary?

It has been said that the difference between ordinary and extraordinary is that little “extra.” Well, I will now share with you one example of how this platitude applies to automotive service.

The scenario began when my wife’s 1999 pickup started having spider cracks in the paint and even deep cracks reaching down to the primer, along with pieces breaking off just above the windshield.

So, being a technician who has never professionally performed body work or painted a vehicle, I needed an expert. Enter a friend-of-a-friend, who came highly recommended and has an established business in our community.

I set up an appointment, left the truck with the shop for 10 days and picked it up after hours on a Friday. Being a trusted friend-of-a-friend, we paid by credit over the phone and had the shop lock the keys in the truck. When my wife arrived to pick up the truck, she hopped in – happy to have a “crack-free” paint job – turned the key and proceeded to pull out of the lot.

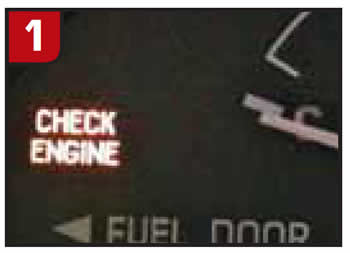

She started down the block but within a few minutes called me on the cell phone to tell me the “Check Engine” light was on and there was a banging noise coming from the front. We swapped cars, drove one block and then pulled over. The truck was running badly, and it was serious enough that I needed to try and find the reason right there. After hunting around for a while on the side of the road, I found that the mass-air-flow (MAF) sensor was unplugged. Plugging this in made it run better, but the “Check Engine” light stayed on all the way home.

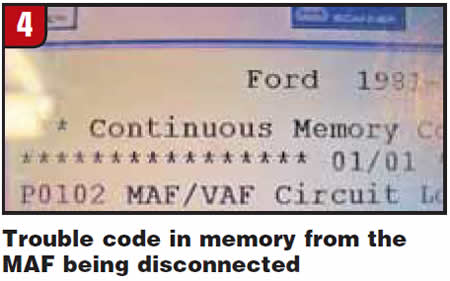

I couldn’t figure out the thumping/banging noise that happened over bumps. It sounded like a tool left in a fender, but I could not find it. When we got the truck home, I found out that the sound was the right step-side bar; both bolts in the front of the bar were stripped out, and one bolt was missing. The bar was loose and flopping (they had both been removed for painting).

My wife and I talked it over, and since we were not impressed with our initial visit to our friend-of-a-friend’s body shop, we felt uncomfortable taking the truck back to them.

Quality control

This experience had me evaluating my own sense of quality control. Do I hand the keys back to my customer with confidence in the job I’ve done? I like to think the answer to that question is always “Yes.” I would be mortified if something simply fell off a vehicle I had just worked on and charged a customer more than $1,000 for. Additionally, I would hope that a post-repair test drive would reveal a sensor I had forgotten to plug back in, giving me the opportunity to catch my mistake before my customer does.

In my situation, my wife and I decided to pull the step-side off and repair it ourselves. We drilled and tapped out the stripped holes and then attached the bar with four new fasteners, some of them oversized. We also repositioned one of the gaskets on the left bar (three of the four gaskets were not seated correctly). I also used my scan tool to verify that the MAF code was the only one in memory, and I erased the code to extinguish the “Check Engine” light.

When these things happen to you and me, we can repair the issues with confidence and never have to deal with a business we perceive as “substandard” or – worse yet – incompetent. If this were to happen with one of your customers’ cars, would they call you to bring the vehicle back to you? Would they be surprised, angry or disappointed?

Will I return to this body shop for future repairs? No. Will I recommend this body shop to others who frequently ask for a referral to a body shop? No. My wife checked the Better Business Bureau regarding this business and there were no complaints. Will ours be the first? Perhaps.

How did the body shop handle my letter detailing our situation? No response. My friend who referred me is embarrassed about it.

How would you deal with this situation? If you were me, would you have returned to the shop or repaired the truck yourself? If you were the body shop owner, would you have ignored a customer’s concern in written form? Of course you would not, and that is one reason I’m so surprised at the lack of response from this business. In Bob Cooper’s June 2006 AutoInc. article titled “Putting a Price on Complaints,” he points out that an average complaint can cost $179 and says, “If you think $179 is a big number, please bear in mind we’re talking about customer ‘complaints,’ not warranty ‘repairs.’ In addition, we haven’t taken into consideration the economic damage to your reputation, the damage to employee morale, the loss of income that’s associated with the loss of a customer or the direct cost of any repair.”

Wow! So being detail-oriented not only can save a customer from complaining, which costs $179, but can save the added cost of repairing a comeback.

Failing fasteners

It happens to all of us: we take a part off, then when we reattach the part, the fastener strips, breaks, just feels “wrong” somehow – like it won’t last long under stress. If you use a torque wrench, then this point becomes quite obvious. I can think of a certain manufacturer’s brake-caliper bolts that like to strip when being removed/reinstalled. I have used the “HELP!” line of aftermarket clips, bolts, springs and handles to repair my customers’ cars, and I have been forced on occasion to call the dealer for that one-of-a-kind clip as well.

In the case of the step-side for my truck, I feel that the body shop should have called me and presented me with options that would repair the failed threads and result in a lasting repair. As rusty as those threads looked, they could have made a case for welding on new end plates with new threads, which in my opinion would have been the ultimate “great” repair.

The bottom line: Quality cannot be compromised when cars are repaired, and customers should never be surprised the way my wife was when picking up her truck. If we have to wait for the “right” clip, or even weld, grind, tap and drill a part to ensure it is “right,” we need to communicate that information to the customer so they can make an informed decision. We all need to be diligent about the “little things” when we finish a job. Who wants to have the “Check Engine” light pop on or have parts fall off on their way home?

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. He can be reached at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.