Technically Speaking

- Subject: Shift complaints caused by valve-body bore-plug wear

- Unit: Toyota U150/250

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

Valve-body bore wear has become so common that one can just about predict which bores will wear when a new transmission hits the streets. Any valve that is regulating is up for grabs. TCC, pressure control, clutch regulating valve, whatever you want to call it, if it moves back and forth quickly and consistently, more than likely it’s going to wear the bore.

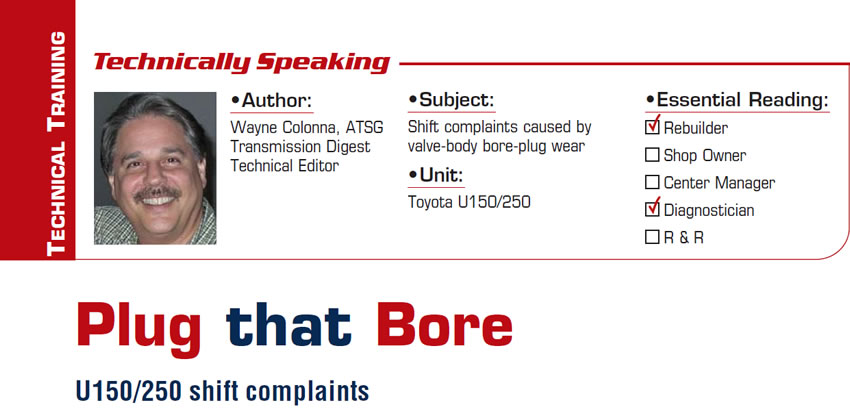

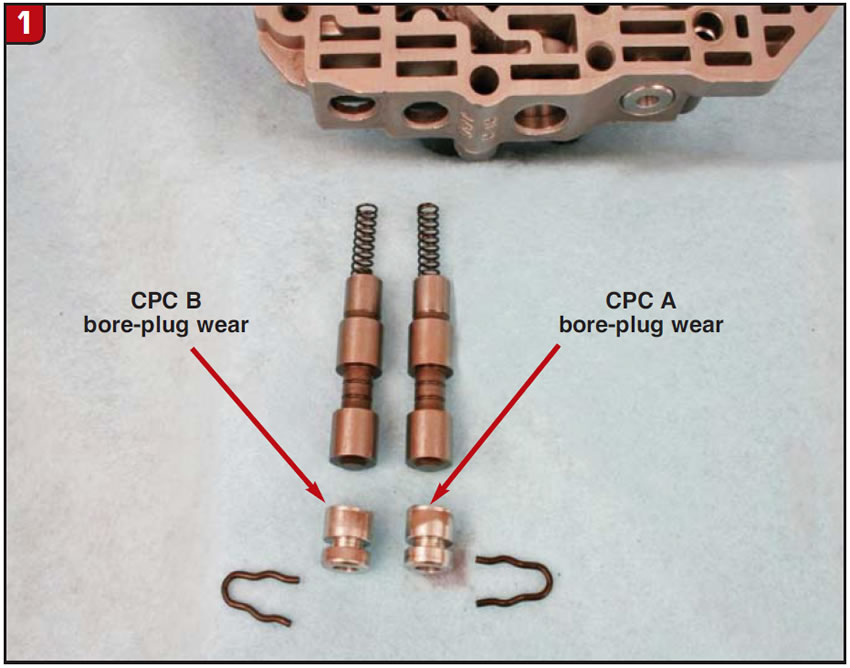

Another pesky little problem that develops in these valve bodies that is not mentioned enough are some of the bore plugs that retain these regulating valves in their bore. Many technicians have learned the bore-plug wear issue the hard way with Honda transmissions (figures 1 and 2). Clutch-pressure-control valves A and B are known for this problem, and it is no joy to learn about it after the job is done. And isn’t that the way it seems to go, to learn about something with the worst possible transmission to learn from? It’s not as though you can just drop the pan and pull the valve body on these units.

The Toyota U150/250 is no exception to valve-body bore-wear issues. But just as important are bore-plug wear or leakage problems.

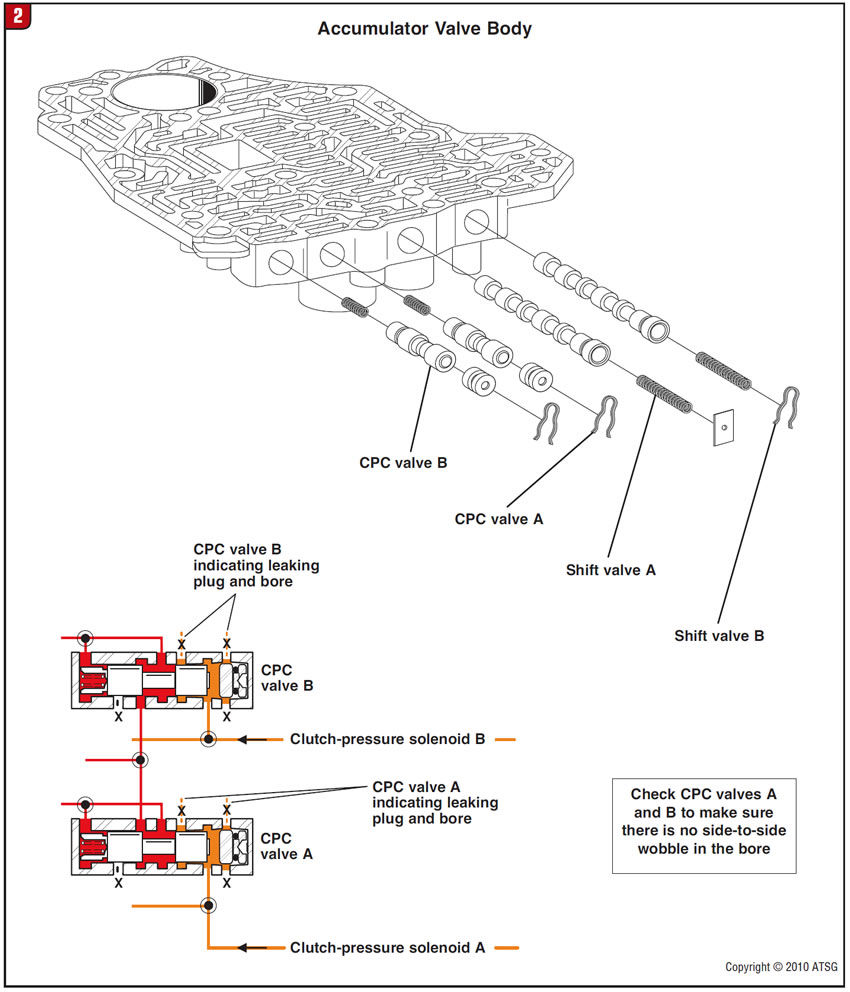

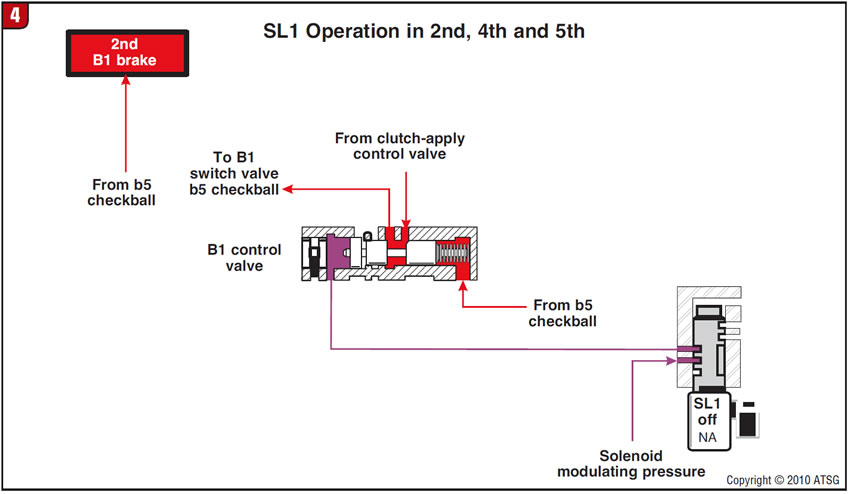

Take a look at the partial hydraulic schematic shown in Figure 3, where we will be using the operation of the SL1 solenoid as an example.

This solenoid is used to control the application of the B1 clutch (second brake) on both the 1-2 and 3-4 shifts and holds the clutch on in fifth via the B1 control valve. This is a normally applied (NA) solenoid that when energized turns the clutch off and as it is pulsed off applies the clutch by regulating the B1 control valve.

Figure 3 shows the SL1 solenoid energized in first gear preventing oil from passing through the solenoid to the B1 control valve. Figure 4 shows the solenoid turning off, and as it does it sends solenoid signal oil to the B1 control valve between the bore plug and the valve itself.

The solenoid regulates the stroke of the valve, which ultimately regulates line pressure to the B1 clutch for a controlled shift into second gear. The same process occurs during a 3-4 shift, and then the solenoid needs to stay off to hold the clutch for both fourth and fifth gears.

If this bore plugs develops enough of a leak, SL1 signal oil will have difficulty stroking the valve, resulting in a flare or slide shift or no shift at all. Or, the bore-plug retention may be sufficient to allow for a decent shift, yet during a cruise in fifth gear pressure could leak past the plug, un-stroking the valve and causing the transmission to suddenly neutralize.

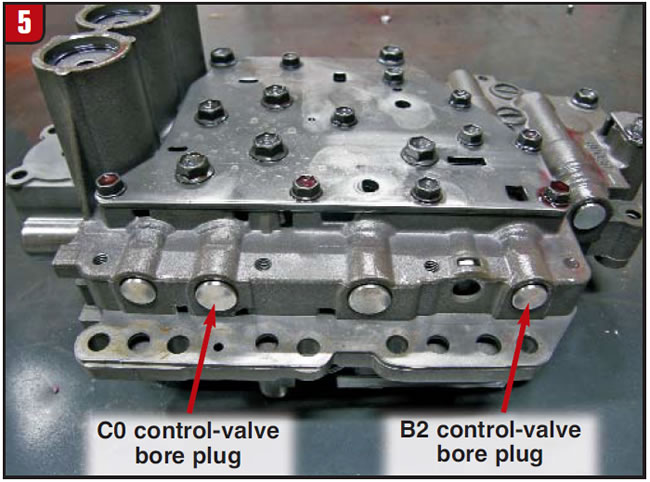

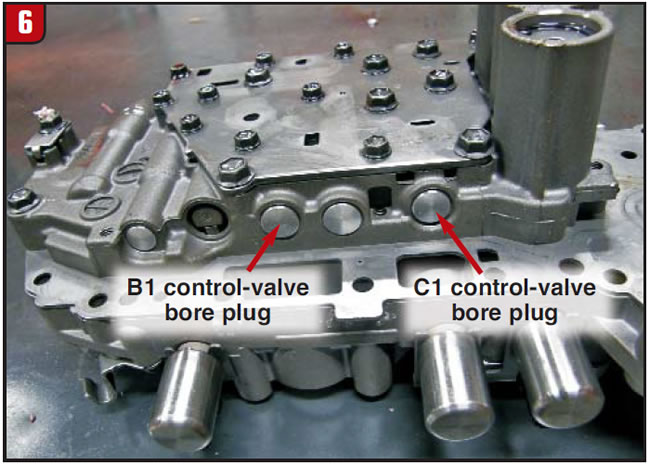

In addition to the B1 control-valve bore plug, there are three more control valves in the U150/250 valve body that rely on good bore-plug retention. They are:

- The C0 control-valve bore plug – Controls the application of the C0 direct clutch during a 2-3 shift and must hold the clutch on in third, fourth and fifth.

- The C1 control-valve bore plug – Controls the application of the C1 forward clutch during a garage shift into Drive and must hold the clutch on for first, second and third.

- The B2 control-valve bore plug – Controls the application of the B2 low-reverse brake in manual low for engine braking and must hold the clutch on in first.

With the exception of the B2 control-valve bore plug, solenoid-performance codes and gear-ratio codes may be the result of poor bore-plug pressure retention.

See figures 5 and 6 for their locations.

An indication that one or more of these plugs are beginning to leak would be bumpy shifts up and down due to the adapts adjusting for the leak. So it may be a good idea to inspect them during repairs and, if you find a leaker, plug that bore!