Tech to Tech

- Subject: Transforming a retired patrol car into a drag racer

- Vehicle Application: 2006 Dodge Charger

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Brian Manley

Rebuild on Dodge Charger helps car be more competitive in youth initiative that promotes safer racing venue

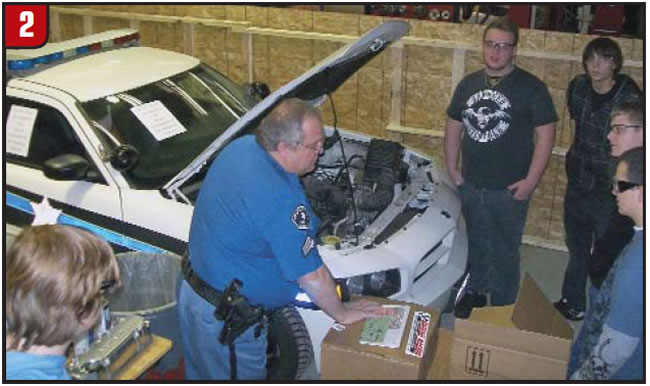

As professional technicians, we may often feel the desire to give back – to use our expertise for the betterment of our community. Recently, our shop adopted a special project from our local sheriff’s department: a newly retired-from-the-fleet 2006 Dodge Charger. The sheriff, who initiated this project, is a drag racer from way back, and he wanted us to “build” the car for our local one-fourth mile drag strip, Bandimere Speedway. Our speedway hosts a program called “Take it to the Track” – an initiative aimed at getting young drag racers off the street and onto a safer venue.

The reward for racing at the track is a head-to-head drag race with a police car! The more we talked about this project, the more excited we became and dived right in.

The sheriff wanted to be more competitive with his Charger so he could win more than one third of his races. The Charger – here in Metro Denver – ran the quarter mile in 15.9 seconds and averaged 88 mph with the stock 5.7 Liter Hemi engine, automatic transmission and 2.80 differential gears.

Before embarking on this project, we evaluated the Charger thoroughly to ensure it was worthy of the $5,000 investment, and to ensure there were no safety concerns. Even though it had been in service for five years, with just more than 80,000 miles, this Charger had a long life left.

We accepted the project, and with a generous donation from the Fraternal Order of Police, the sheriff delivered:

- A higher-lift roller camshaft and new roller lifters

- A higher-stall torque converter

- A cold-air intake and filter

- A larger throttle body

- Headers and a cat-back exhaust system

- A Diablosport hand-held flash reprogrammer

- A new ring-and-pinion set with 3.68 ratio

- Full engine-gasket set, fluids and filters.

This can be an overwhelming project, especially when it is a part-time proposition (we projected three months for completion with volunteer labor). The first order of business – in our mind – was to pull the Hemi out and get it on a stand. We would then be able to check off the camshaft replacement, torque converter, headers and intake system in one operation. To facilitate this process, we pulled the bumper, radiator and core support.

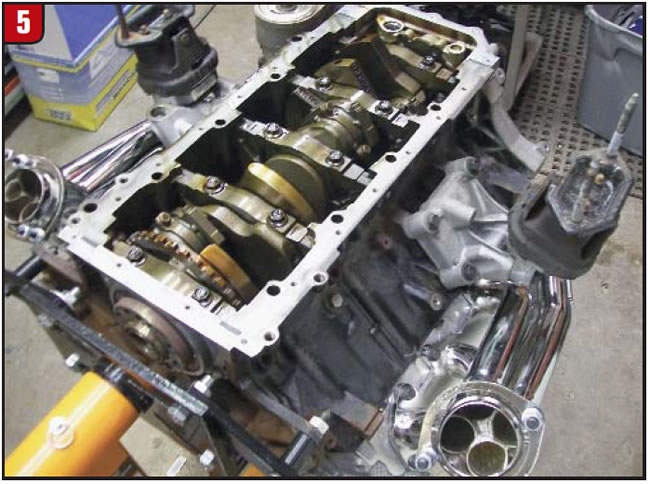

Our 5.7 liter Hemi engine includes a unique feature – the multi-displacement system (MDS) that deactivates four of the eight cylinders when the throttle is closed or at steady speeds. This is accomplished through the use of dual-mode lifters and four solenoids that reduce oil pressure from 16 psi to 3 psi to close the intake and exhaust valves on cylinders 1, 4, 6 and 7.

This presents a special issue when replacing our camshaft; the replacement lifters do not have oil passages, so the MDS will not function when the solenoids are activated. At this point, we continued with our build knowing we would face this issue, and that we could deal with it through the powertrain control module (PCM). More on this later.

Once apart, the engine looked like it was in great condition, and we made the decision to not bother the crankshaft, bearings and pistons. We simply swapped the cam and lifters and replaced all of the gaskets. After checking the cylinder heads for flatness, we carefully resealed all covers and installed the new headers. We were getting excited at this point, and we tried to invest as much time as we could to expedite this process, especially when we have a perfectly good engine scattered all over two benches for two weeks!

Before reinstalling the engine, we fitted the new torque converter, and, unfortunately, we had to remove one of the new headers before the engine would drop in. Point of note here: Be certain to compare all components when embarking on an endeavor such as this; we compared most of the pieces, but the torque converter proved to be slightly different, putting the brakes on our project for two days. Once the engine sat in place, many volunteers spent many hours trying to remember where all of the fasteners went for the front of the car, but we eventually figured it out!

At the other end of our hot-rod-in-progress, we removed and disassembled the differential. We could definitely see the influence that Daimler-Benz had on this vehicle while removing the flexible, rubber coupler at the flange. It is important to mark mating surfaces when removing this shaft to prevent imbalance issues. It is also required to measure rotating torque before disassembling so it can be replicated later. A frustrating issue that we ran into here is that a case spreader needs to be used to remove and replace the ring and pinion gears; we do not have one. As much as we wanted to set up this differential ourselves, there were too many factors that led us to ask our friend at Chrysler to assist us – a friend with the case spreader and assortment of select shims, etc. that makes the job less frustrating.

I have to say we ended up with a nice drive pattern!

So, after 10 weeks of part-time volunteer labor involving six technicians, we were ready to install the differential, new exhaust system, start the engine and take her for a spin. I could not wait for our hot rod to be running because I desperately wanted to play with the flash reprogrammer and “tweak” different variables in pursuit of optimal performance.

At this point the track was set to open in two weeks! In our next installment, I will reveal how (or if) the car ran at Bandimere Speedway and special issues that evolved with the powertrain control system. See you next time with the track report!

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. You can reach him at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.