R&R Tech

- Subject: Check Engine light on, transmission in limp mode

- Unit: 545RFE

- Vehicle Application: 2003 Dodge 1500 pickup

- Essential Reading: Rebuilder, Shop Owner, Center Manager, Diagnostician, R & R

- Author: Randy Peterson

A few months ago a customer brought in a 2003 Dodge 1500 pickup with a 5.7 Hemi engine and 545RFE transmission. The Check Engine lamp was on and the truck would not accelerate from a stop unless you put the transmission in second gear.

I started the preliminary check procedure by checking the fluid. It was full, not in great shape but no burnt odor. Next, I scanned for diagnostic trouble codes. The engine control module (ECM) stored a couple of EVAP codes and the transmission control module (TCM) had a P2706 – MS (multi-select) Solenoid Circuit. Oddly enough it did not have a P0700 (Trans Control System Malfunction) stored in the ECM.

This vehicle uses an ECM and separate TCM. A short road test confirmed the customer’s concerns. I cleared the DTC and road-tested it again to see whether the code reset, and it did. Further diagnostics were required. The vehicle owner authorized the diagnostics, and we began the process.

The first test I performed was on the electrical systems. This included testing the battery and verifying that the starting system and the charging system were operating correctly. Free-state fully charged battery voltage should be around 12.6 volts. 12.4v is already considered 25% discharged. Cranking voltage should never drop below 9.6v, and good running voltage usually is around 14v.

It amazes me how many times this step is overlooked in the diagnostic procedure. Low voltage, poor grounds and faulty alternators can wreak havoc on electrical components. You want to be sure if you find problem electrical components that a bad battery or faulty alternator does not cause the replacement components to fail. Thanks to Vince Fischelli for teaching me that.

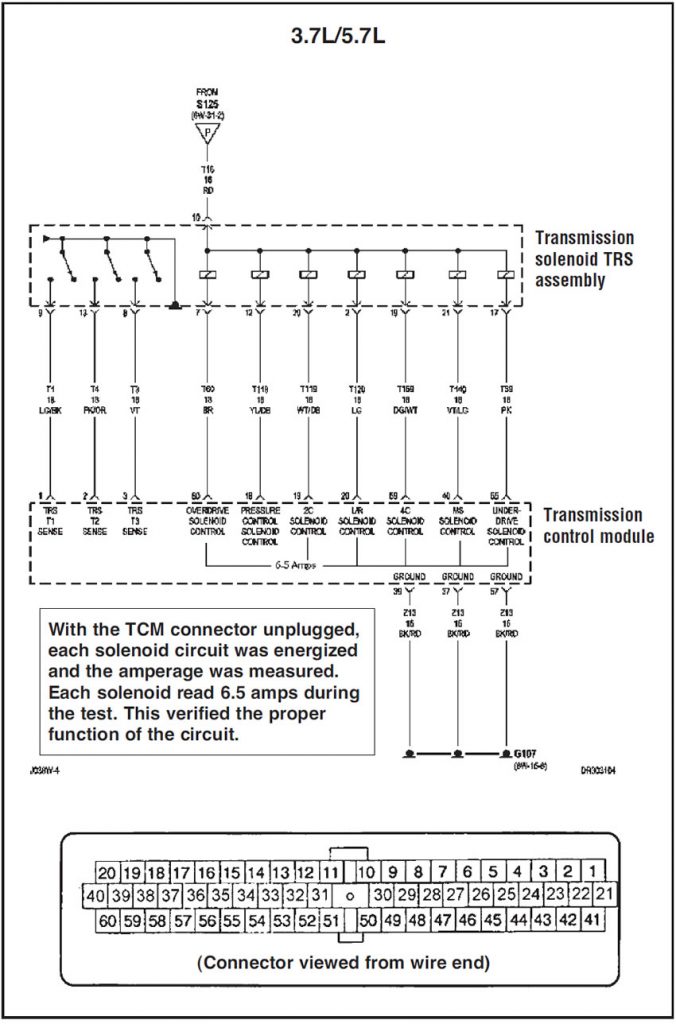

Next, I printed off a wiring diagram and the published diagnostic procedure. I studied the diagram, gathered solenoid specifications and determined my next point of attack.

The TCM is the 60-pin type, similar to the ones used on the 604s and 42LEs. I located the TCM and harness, identified the pin(s) I wanted to check and started with (multi-select solenoid control) pin 40. I performed a simple resistance test to see whether there was an open from the TCM to the solenoid, and there was not. I needed to verify my findings so I tested all the solenoids. They all tested the same.

We all know that a resistance test is no indication of a properly working system, so I load-tested the solenoids and measured the amperage while they were activated. This tells me whether the solenoid is working and whether it continues to work once it gets hot.

I was not able to use bi-directional functions because the TCM would go into failsafe and shut off the relay. With the TCM disconnected I ran fused power to the connector. With this system, the solenoids are grounded and the TCM supplies power. I was able to determine that from the wire diagram. I powered pins 19, 20, 40, 55, 59 and 60. All the solenoids were 6.5 amps, including the MS solenoid. That is within the normal operating range. I ran the test again with the same results. My conclusion was a faulty TCM. I reconnected the TCM and road-tested the unit. The code returned and it went to limp mode.

We recommended a TCM replacement and an ECM re-flash. The owner declined and took the vehicle. Who knew that testing all the solenoids at this time would pay off later? The story does not end here.

The owner took the vehicle to the local Dodge dealer for a second opinion. I can understand a second opinion when there is a large cost involved. The dealer advised that the solenoid was bad and needed to be replaced. This repair was about half the amount we had estimated, but remember that the dealer was doing something completely different from what we recommended. The owner liked the dealer’s price and authorized the repair. Needless to say, it did not fix the problem. The dealer then told the customer, “It must have a bad transmission then.” The owner left the dealer $450 poorer, and the vehicle was still doing the same thing.

The owner heeded the advice of the dealer, bought a carry-out transmission from our company and installed it himself. Shortly after the installation we received a call saying our transmission did not work and we needed to fix it. The vehicle was brought in and I scanned it for trouble codes. A few months had passed since the vehicle was last here and I did not recognize it at first. It had a DTC P2706 stored just as before. Again, there was no P0700 stored in the ECM. Just to be sure, I ran the diagnostic test again. My conclusion was the same: a faulty TCM.

The owner bought a TCM from the dealer that recommended the transmission exchange. I’m not sure how that discussion went, but he proceeded to install it in our parking lot after hours. The next morning I was to check the installation and perform any pre-road-test functions.

I started my road test, satisfied that the vehicle would be fixed. When I started to take off, the Check Engine lamp came on and it was again in limp mode. I was shocked to say the least. What happened? I checked the codes – no P2706. This time it was P0750: L/R Solenoid Circuit Error and still no P0700 stored in the ECM. I knew from my previous test that all the solenoids were good. I was so familiar with the test that I did it again. I concluded that the solenoids were good and that the replacement TCM must be bad. I called the dealer, which supplied the owner with a warranty replacement. The owner installed the TCM, and I performed the pre-road-test functions and drove the vehicle. Yahtzee! It worked, and it worked great.

I felt very comfortable that my diagnostic procedure was correct. It verified all the working circuits under load. It also verified the support systems; battery and charging system were in good working condition and not contributing to the failure. I tested ALL of the solenoids, not just the one in question. That would help me later on when faults kept recurring, and it provided a good comparison of the solenoids.

Why are parts replaced without proper diagnosis? Is there a lack of knowledge or carelessness? Do technicians not understand the circuits and how they work?

There are outstanding training programs out there, but you have to take the classes and then practice what you have learned.

We charge for diagnostic time. It’s an important process for your company’s credibility, and it doesn’t waste the customer’s money with unnecessary parts replacement.

Randy Peterson has been with Certified Transmission since 1992 and is the diagnostician at the company’s facility in Gladstone, Mo.