Tech to Tech

- Subject: Emissions diagnosis and repair

- Vehicle Application: 1992 Oldsmobile Cutlass

- Essential Reading: Diagnostician

- Author: Brian Manley

With older vehicles on the road, emissions issues will be a more-common occurrence

How often have you had a customer with a high-mileage, 20-year-old vehicle say, “I just need it to last one more year”? With the average age of vehicles on the road more than 10 years, I am seeing more “20-somethings” coming in my bay for TLC.

A customer recently brought in her 1992 Oldsmobile Cutlass with a 3.8-liter engine, 138,000 miles and a failed emission report. In our metro Denver area, we all must pass our centralized emission test – or we cannot renew our license plates.

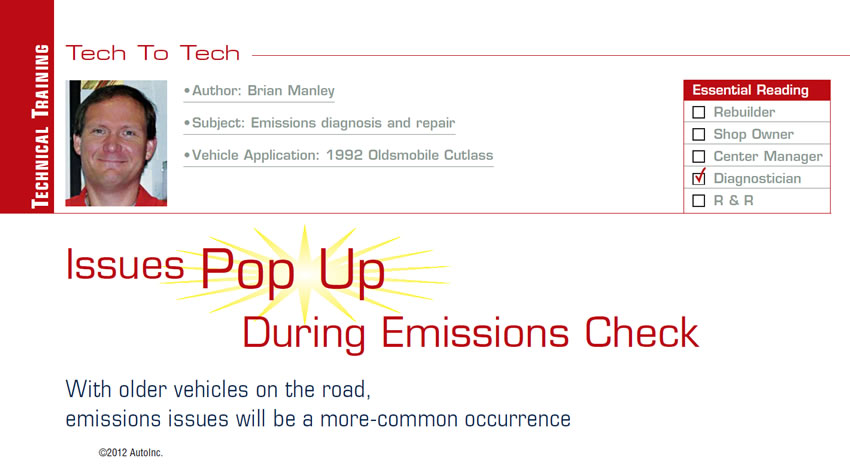

Figure 1 shows the first test result: The Olds vehicle failed the test with an 8.4-grams-per-mile (GPM) measurement for hydrocarbons (on a 1.5-GPM limit) and also with a 64.8-GPM reading for carbon monoxide (on a 15-GPM limit).

Because Denver’s enhanced IM240 program uses a dynamometer and a constant-volume test using grams per mile as a standard, I can’t replicate those same test conditions in my bay. However, I can use my four-gas analyzer to baseline my Oldsmobile and use those numbers to gauge emission reductions after performing my repairs. Figure 2 shows my initial measurements: high CO for idle, very high HC and CO2 that is far too low. I could also feel a hard misfire with the engine in drive.

Because the high HC was almost certainly a result of the seat-of-my-pants misfire, I felt confident that the root cause could quickly be determined. At this point, I felt I had to be dealing with two different causes for two failed gases. The high CO could be caused by many reasons for a rich air-fuel mixture, including a sensor that could be “lying” to its powertrain control module (PCM). The low CO2 – indicating low engine efficiency – underscored the fact that the catalytic converter was not receiving enough oxygen to perform its job correctly. The chemistry of combustion is fascinating to me, and I looked forward to a fun diagnosis.

A power-balance test revealed that cylinder No. 3 had no spark from its coil, but its companion cylinder had strong spark (Figure 3). We found and fixed a defective coil pack for cylinders 3 and 6, and during a complete visual of all tune-up items, we recommended – then replaced – spark plugs, wires and air filter.

Figure 4 shows my four-gas numbers after our repairs.

At this point in the repair, we had spent a fair amount of labor and parts in an effort to reduce both HC and CO emissions, and even though I had a feeling we had repaired the cause of the high HC, I knew we had another reason for the high CO. That being said, I wanted to see where I stood at this point; I wanted to see exactly how far the HC had dropped, and what effect it would have on the CO and CO2. I knew the customer needed this car to pass its test, but I wanted to keep the cost as low as I could. I did not think such a high CO number could be caused by a dirty air filter, but I knew the HC numbers would be drastically reduced now that all six cylinders were firing.

We drove the customer’s Olds back to the test center for her free retest (free within 10 days) to see how the numbers looked.

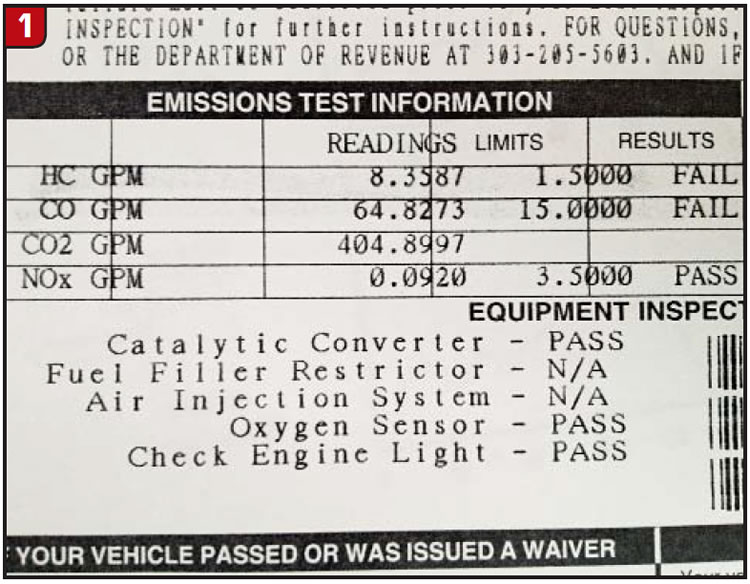

Figure 5 shows the readings from the retest: HC dropped to 1.8 GPM (almost below the 1.5-GPM standard) and CO actually increased to 82.8 GPM! I thought it interesting that the increase in CO had been reflected in my four-gas readings as well. I felt that when I found and repaired the high-CO condition, the high HC would drop into acceptable limits, and the high CO is what I targeted next.

It was apparent to me that this poor vehicle had not had any TLC for quite some time, and I wanted to complete a comprehensive examination before sending her back for her next emission retest.

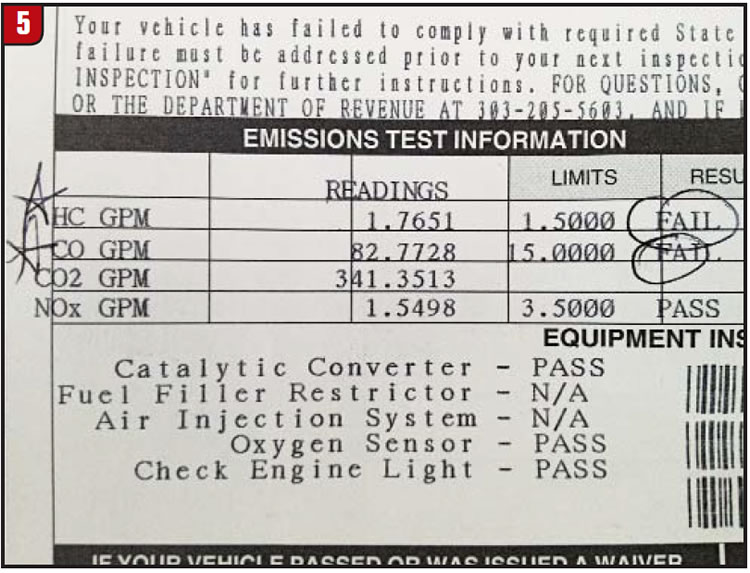

Because this was an OBD-I vehicle, I scanned the vehicle for codes and scrutinized PCM data, where I found no codes, but I did find a flat-lined oxygen sensor and long-term fuel-trim numbers at 149. These two facts pointed to a dead O2 sensor, so I hooked up my lab scope to confirm what my scan tool was telling me.

Figure 6 shows an average output of 553 millivolts, and minimums and maximums that remained close to home. This could certainly cause high CO and high fuel-trim numbers. I then checked for O2 response and activity by introducing propane, and then causing a large vacuum leak, but it still hung out around 500mv and would not go above or below this limit.

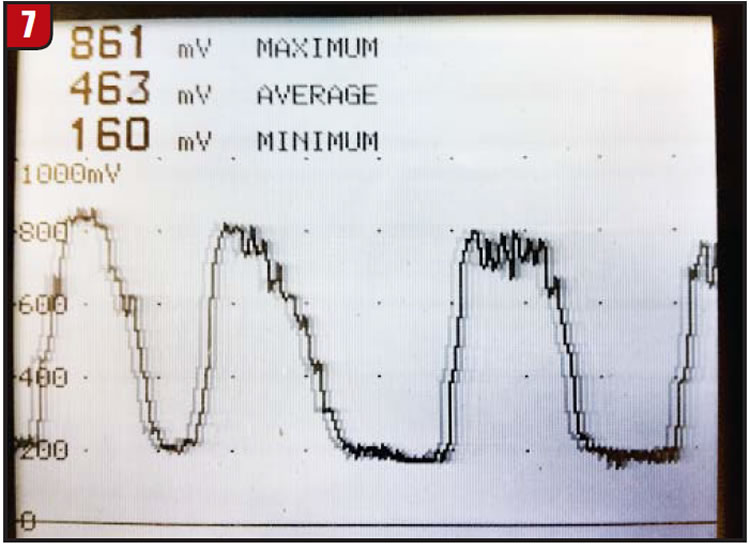

I installed a new sensor, and Figure 7 shows how active it is supposed to be when functioning properly!

After the new sensor, long-term fuel trim dropped back below 130, and it passed the response test by rising to a maximum of 861 mv and dropping to a minimum of 160 mv; this is considered active. The CO2 readings on my exhaust analyzer went way up, and the CO and HC came way down (Figure 8).

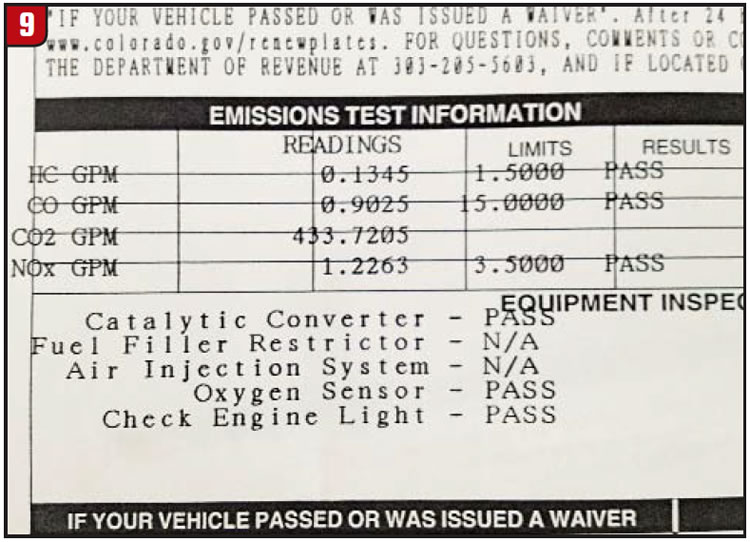

The final test numbers (Figure 9) show passing values: 0.135 GPM HC on a 1.5-GPM scale, and 0.903 GPM on a 15.0-GPM scale! I was impressed with how low the numbers are supposed to be for a healthy, fuel-injected 3.8-liter engine. I felt good that we were able to reduce the emissions so drastically but, more important, my customer had a reliable vehicle for one more year.

While reflecting on this repair – and other similar emission failure/ repairs – I wonder how many vehicles like this are running around outside emission-control areas, and how many high-polluting cars escape much-needed maintenance and repairs. I felt the same way 30 years ago when Colorado replaced our vehicle-inspection program (brakes, tires, lights) in favor of our first-ever tailpipe-emissions testing program. To this day I wonder how many vehicles are running around on the roads with me that have bald tires, poor brakes or loose steering systems.

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. He can be reached at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.