Body of Evidence

- Subject: Similarities and differences in valve bodies

- Units: Ford 6F50, GM 6T70

- Essential Reading: Rebuilder, Diagnostician

- Author: Joe Cangelosi

The 6F50 and 6T70 transaxles were developed as a joint effort between Ford and General Motors. Because this was a joint effort, as you can imagine many of the internal parts are very similar or almost identical. In this article we talk about the solenoid body and what is similar but different.

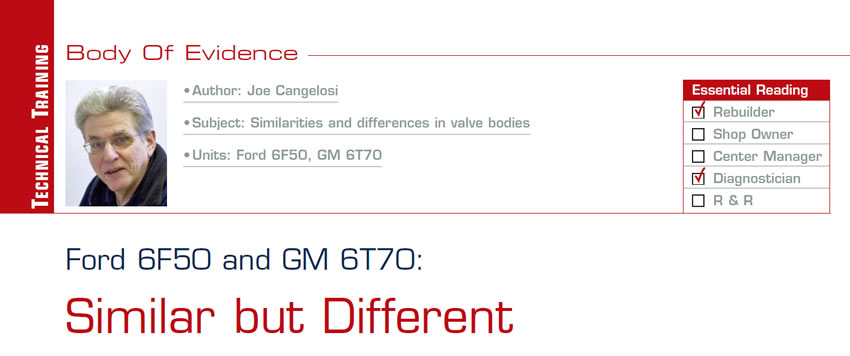

We’ll start with the Ford 6F50 solenoid body (Figure 1). It contains a transmission-fluid-temperature (TFT) sensor and seven solenoids.

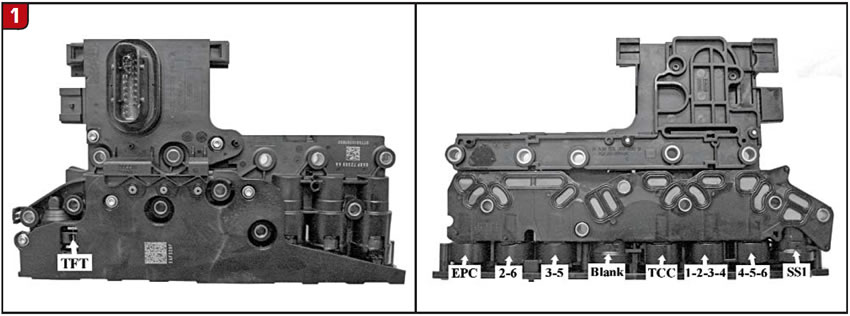

Six of the solenoids are pressure-control (PC) solenoids. Of the six PC solenoids three are normally low (NL-low pressure) and three are normally high (NH-high pressure). For ease of identification I have listed the PC solenoids by the clutch they apply or their function (Figure 2). Ford and GM number the solenoids differently, but the function and firing order are the same for either manufacturer.

The three NL solenoids are the intermediate or 2-6 clutch, forward or 1-2-3-4 clutch, and the torque-converter clutch. The three NH solenoids are the line-pressure-control or PC, direct or 3-5-Reverse clutch, and overdrive or 4-5-6 clutch (this solenoid also regulates pressure to the low/reverse clutch in Drive 1st gear and Reverse).

The remaining solenoid (SS1) is a normally closed (NC) on/off type that controls the low/reverse clutch. SS1 is turned on below 3 mph in Drive 1st gear to apply the low/reverse clutch for engine braking.

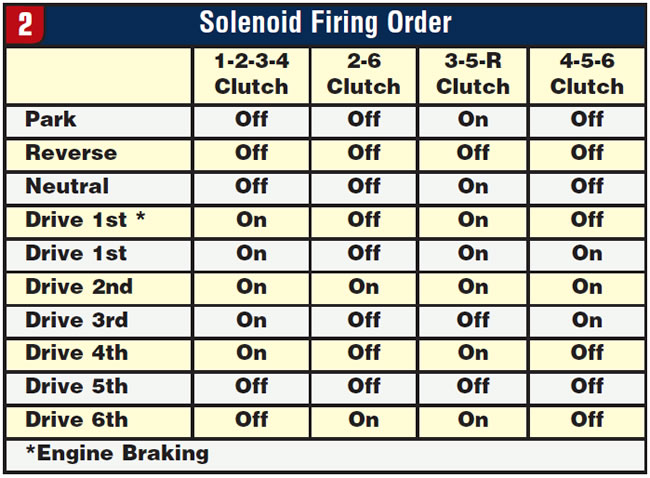

Now let’s look at the GM 6T70 solenoid body (Figure 3). To begin with it contains the TCM, where Ford uses the PCM to control the transaxle. There are also four transmission-fluid-pressure (TFP) switches. As in the Ford 6F50 there are a TFT sensor and solenoids, but GM uses eight solenoids rather than seven.

The first thing that is different is the pressure switches. They are used to tell the control module the position of the four clutch regulator valves in the valve body:

- TFP #1 monitors the 1-2-3-4 clutch regulator valve.

- TFP #2 monitors the 3-5-Reverse clutch regulator valve.

- TFP #3 monitors the 2-6 clutch regulator valve.

- TFP #4 monitors the 4-5-6 clutch regulator valve.

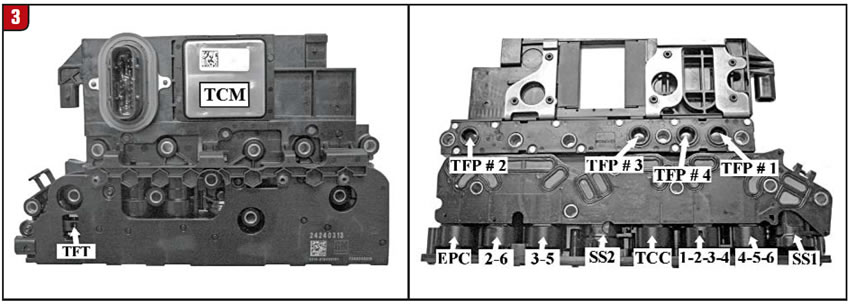

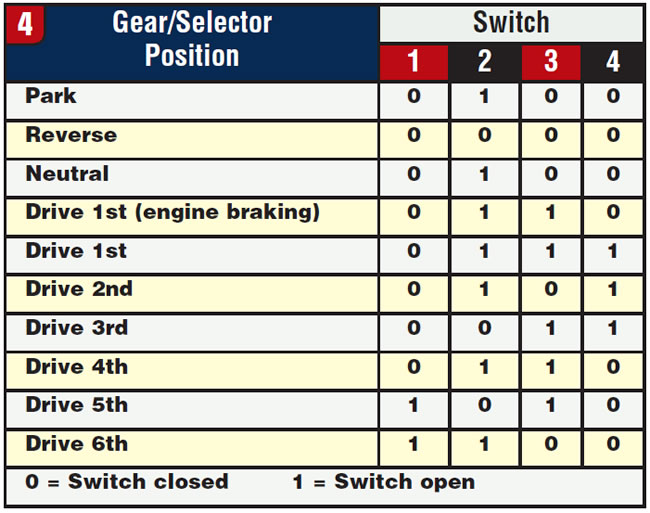

They are all normally closed (NC) and allow electrical current to flow when no fluid pressure is present. Depending on the position of the clutch regulator valve, fluid pressure will be routed to the TFP switch, causing the switch to open and interrupt the electrical current. By monitoring the various combinations of open and closed switches the control module can tell which gear the transaxle is in (Figure 4).

Finally, let’s compare the 6T70 solenoids. As we said earlier the PC solenoids and functions are the same for Ford and GM. However, GM uses two NC on/off-type solenoids instead of one. On GM solenoid bodies, SS1 works exactly the same as SS1 on the Ford.

The additional solenoid, SS2, is used in Reverse to control the position of clutch select valve 3. When Reverse is selected, SS2 is turned off, which exhausts solenoid signal pressure from the outboard end of clutch select valve 3. Reverse pressure from the manual valve combines with spring force on the inboard end of the valve to hold it in the released position. This allows reverse pressure to pass through clutch select valve 3 and enter the 3-5-R clutch feed circuit.

The 6F50 handles the reverse application a little differently. Solenoid feed pressure rather than solenoid signal pressure is constantly fed to the outboard end of the multiplex manual valve. Ford has a different name for the clutch select valve, but the configuration and function are the same. The only difference is rather than exhausting solenoid pressure Ford depends on reverse pressure and spring force to overcome solenoid feed pressure and release the valve.

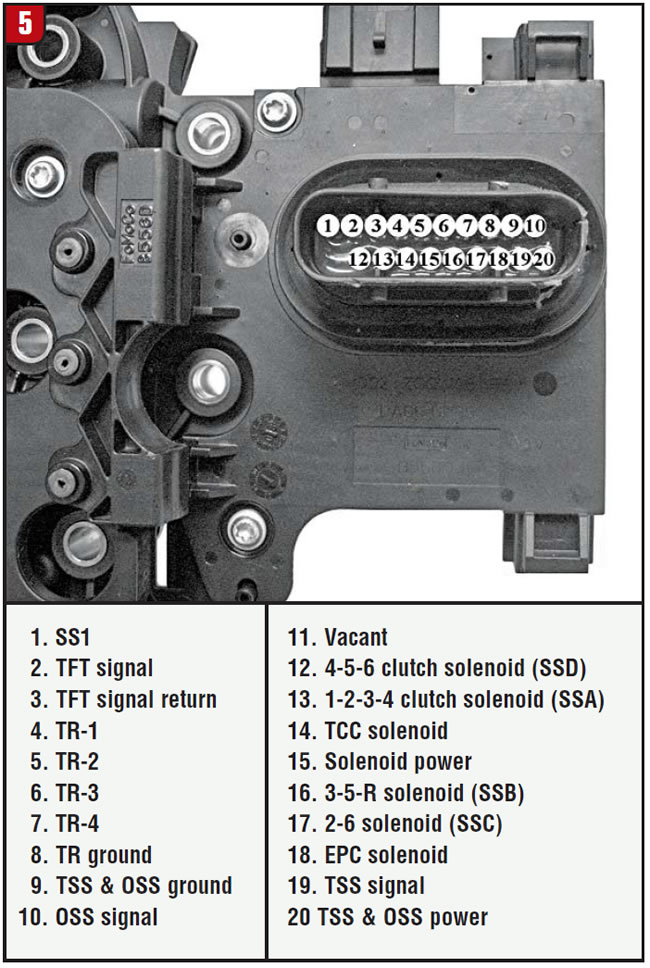

As for service and diagnostics both the 6F50 and 6T70 solenoid bodies are serviced as an assembly. If a replacement is needed for the 6T70 the TCM must be programmed to the vehicle. Ford also has solenoid-body-specific PCM software that should be reprogrammed if the solenoid body is replaced. Diagnostics on the 6T70 can be a little easier in some ways than on the 6F50. Because of the internal TCM, if you have solenoid or TFP- or TFT-sensor electrical codes you just replace the solenoid body. When it becomes harder is that to test any of the other internal electrical components, you’ll have to remove the valve-body cover. Both GM and Ford use turbine- and output-shaft speed sensors and an internal mode switch, all of which plug into the solenoid body. On the 6F50 all the inputs and outputs including the solenoid resistance can be checked at the case connector (Figure 5).

All the specifications for testing the various components are readily available from many sources. One word of caution is that some service publications may show the GM solenoid firing order incorrectly.

Well, there you have it for the solenoid body. I think the more you look at and compare the 6F50 and 6T70 you’ll find there are many other components that are similar but different.

Joe Cangelosi is product-support specialist at ValveBody Xpress.