- Author: Mike Riley

- Subject: Ford 6F50

- Issue: Upgrades

(What starts out the same, may not end the same)

Part 1 of 2 Parts

Much has been written about GM 6T70 six-speed transmissions, rather due to ongoing failures or an endless stream of upgrades. Not only did changes occur early on, but were accelerated to accommodate the GEN 2 shifting strategy that started to be implemented at the end of 2012 and the beginning of 2013. The changes certainly have technicians and parts suppliers hopping, but what of the Ford 6F50?

When Ford and GM got together to jointly develop the new FWD six-speed transmission family, they apparently agreed upon the basic architecture and operation allowing for the unique requirements of both companies. As they say, however, the devil is in the details. While many of the components of the 6F50 and 6T70 are the same, there are certainly differences due to design or the suppliers used. Although GM decided to designate some of the most noticeable changes to the 6T70 as GEN 1 or Gen 2, the Ford changes are mainly designated by the month and year that they occur. Before ordering replacement components for either transmission family, make sure to specify the precise application.

Beyond design changes to address component failures, improvements in shift strategy or even to cut manufacturing cost, both companies have model variations to accommodate torque capacity. The GM models are 6T70/6T75 and the Ford models are 6F50/6F55. Certain high-torque components can be installed into the standard version to improve capacity, if needed. As far as periodic upgrades are concerned on the 6F50, there was certainly more than one or two.

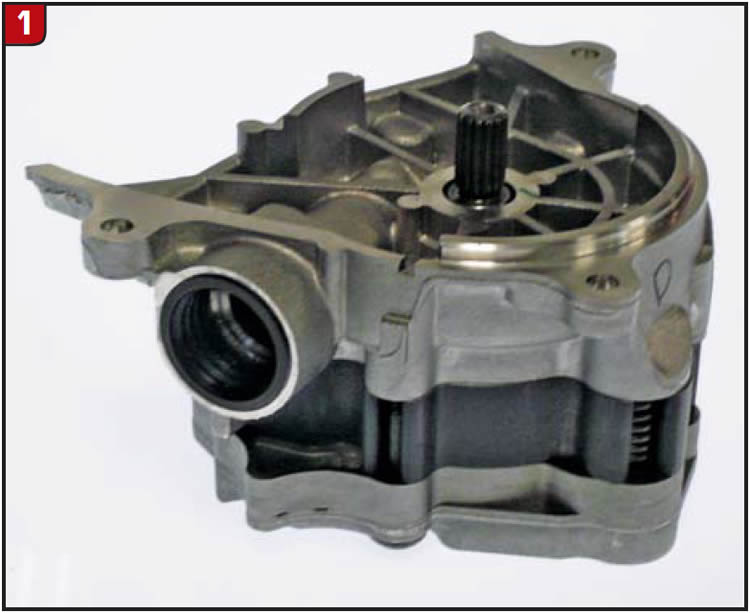

Pump assembly: Both GM and Ford use a chain-driven, remote-access pump that is becoming more plentiful in transmission design due to advantages in fuel economy and performance (Figure 1). The pump is a vane type pump with a movable slide. Depending on application, the rotor can be supported by a bushing or bearing and the end plate must conform accordingly. If the end plate has a hole positioned at the end of the rotor, the pump must use a bearing to support the rotor. A bushing design would allow pressure to exhaust through the end plate hole.

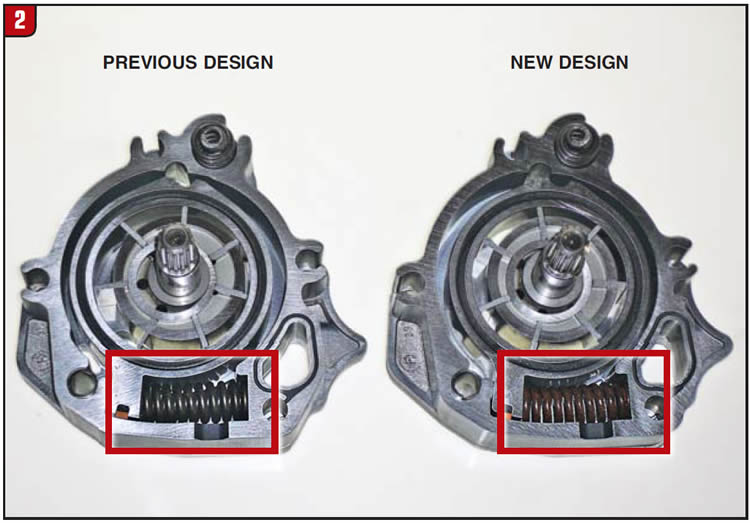

It took GM a bit of time to transition from GEN 1 to GEN 2 design levels, whereas Ford chose February 2012 to cram through several upgrades. Concerning the pump, there was a design change made to the slide spring by switching from an inner/outer type to a single spring with increased tension (Figure 2). The part number for the previous design pump is 8A8Z-7A103-A with the new design part number being DT4Z-7A103-A. The rest of the pump appears to be identical and it is questionable as to the impact on pressure or volume with the new pump.

Rotating clutch assembly: Probably the component with the highest rate of failure on either the GM or Ford FWD six speeds is the rotating clutch assembly, due to the direct (3-5/rev) cushion spring breakage. The housing contains the direct (3-5/rev) and overdrive (4-5-6) clutch pack assemblies and initially the two versions looked pretty close (Figure 3a).

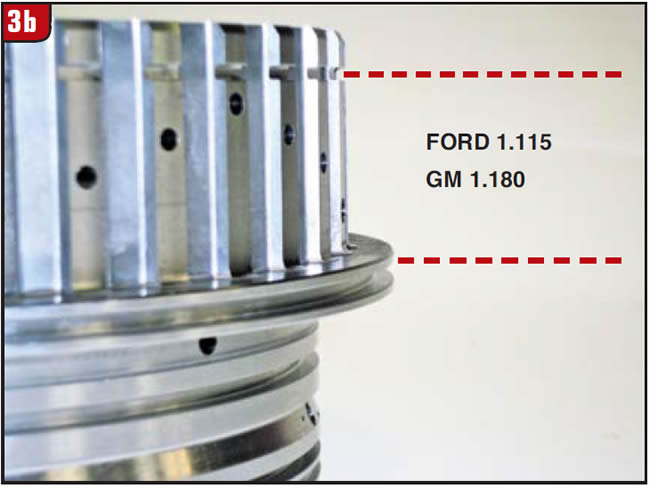

The main difference between the Ford housing and GM GEN 1 housing had to do with the direct-clutch backing-plate snap-ring height. Ford and GM chose to use a different direct (3-5/rev) cushion spring design with the Ford version being thinner and having a lower wave. That resulted in a lower snap-ring height on the Ford housing (Figure 3b).

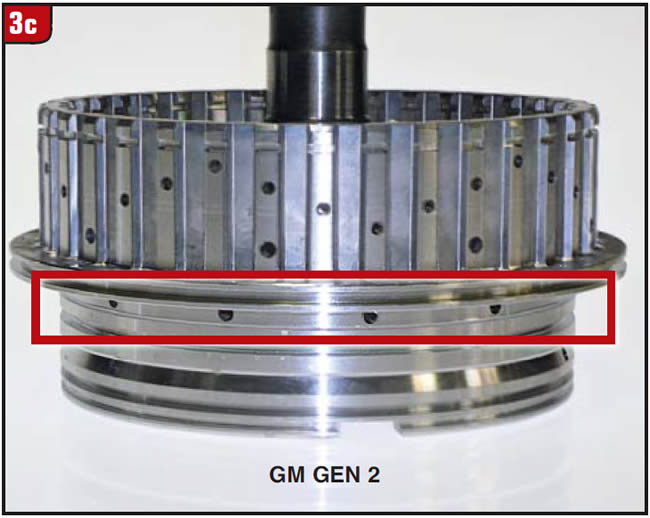

To accommodate the GEN 2 upgrade, GM made a noticeable change to the housing in regards to compensator oil flow (Figure 3c). Ford, on the other hand, has retained the same basic housing design including the overdrive apply piston.

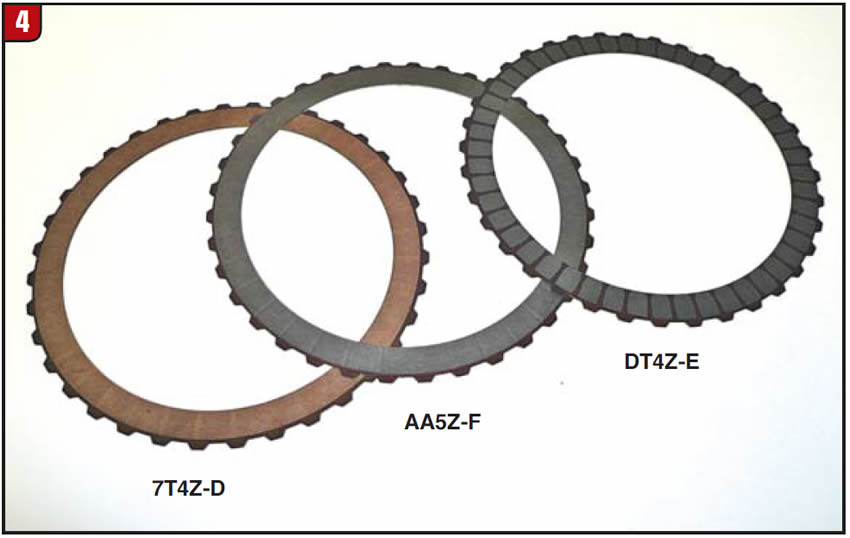

Ford did follow suit with GM in one regard, which was to tinker with the friction plates. From the start, Ford and GM have specified different friction plates for their transmission families involving not only the friction material and grooving pattern, but also the amount of waviness in the plates. GM traditionally has used a gray material whereas, Ford initially used tan. Currently, there are three direct friction plates that Ford offers based upon application (Figure 4). To identify friction plates, Ford uses a center number grouping of 7B164, which would make the early design tan friction on the left of the illustration part number 7T4Z-7B164-D. Beginning in February 2012 additional plates were added such as the gray grooved friction (AA5Z-7B164-F) or the segmented plate on the right (DT4Z-7B164-E). Segmented (button) frictions are produced to save on manufacturing cost, not to improve drivability or durability of the plates.

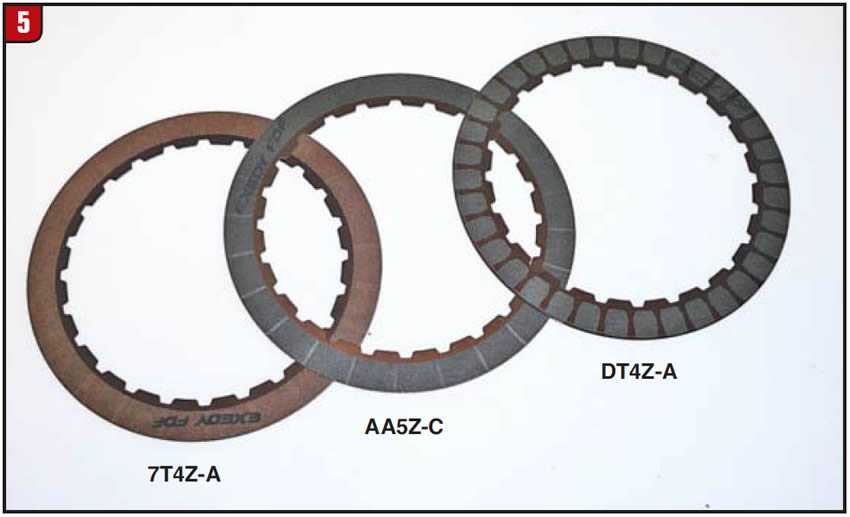

Similar action was taken on the overdrive frictions, starting with a tan plate (Figure 5). The prefix/suffix of the tan plate is 7T4Z-A with the plate in the center being a GM clone part number AA5Z-C. Starting April 2012 Ford switched to a segmented design for overdrive, under part number DT4Z-A. Using the correct friction material can certainly help to avoid shifting issues.

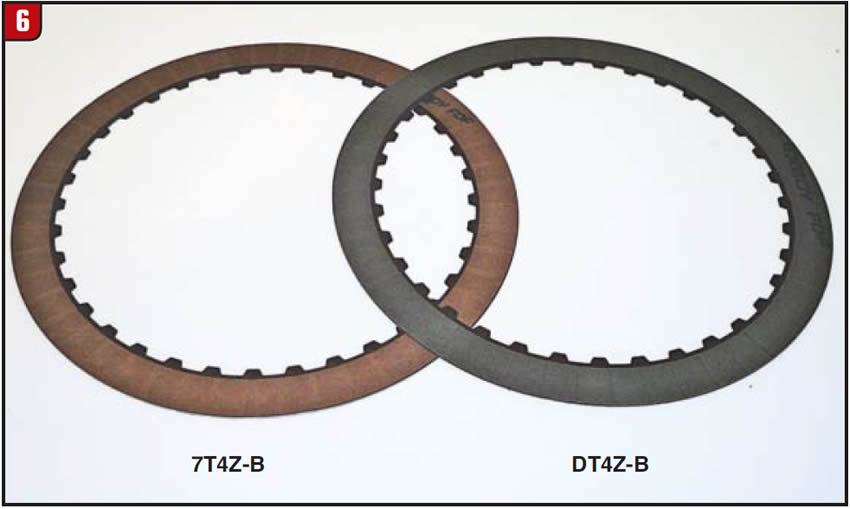

Forward (1-2-3-4) clutch: The forward frictions also got a facelift in February 2012, changing from a tan design to GM gray (Figure 6). Unlike the GM friction, which is smooth, the 6F50 has oil grooves and to date, Ford has not released a segmented version, although that could change.

The forward clutch bonded piston was changed due to material and manufacturer in June 2009 under part number AA5Z-7A262-A (Figure 7). The previous piston part number is 7T4Z-7A262-A. GM made a change to their piston to accommodate a new cushion spring and modified the cutouts for identification. The 6F50 cushion spring remains unchanged, and the new piston can mainly be identified by the molded part number.

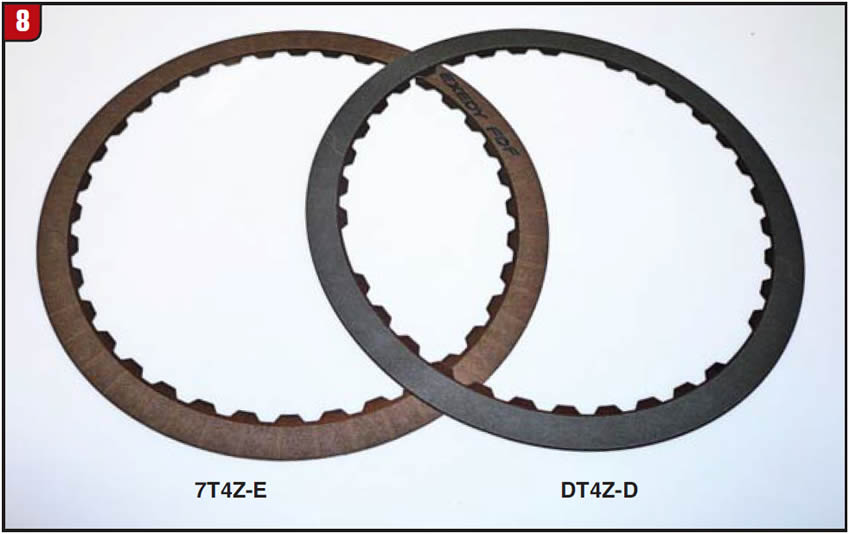

Intermediate (2-6) clutch: The intermediate frictions were changed in a similar fashion to the forward frictions, in that the material was changed from tan the gray (Figure 8). The part number for the tan plate is 7T4Z-E and the new gray plate is part number DT4Z-D. The new friction plate is smooth like GM; however, there are three missing teeth for identification purposes.

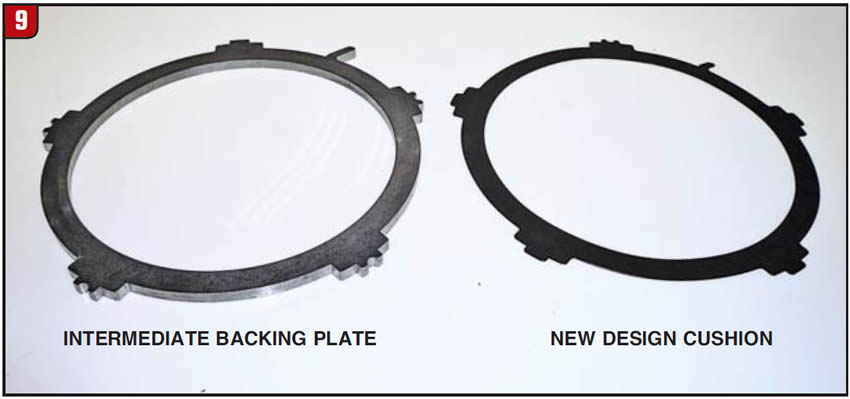

What did change to impact the intermediate clutch was the cushion spring and backing plate, also beginning in February 2012. Ford did not take the same approach as GM did for GEN 2 models. The cushion spring and backing plate should match to avoid clearance issues (Figure 9). The previous design cushion spring part number is 7T4Z-7E085-C and is .045 thick with six waves. The new design cushion spring is part number BT4Z-7E085-A and is .030 thick with eight waves.

The previous design backing plate is 0.160 thick with part number 7T4Z-7B066-B. The new design backing plate is 0.173 thick with a part number BT4Z-7B066-A, which also contains the new design cushion spring.