Standard Issues

- Author: Gabe Vajda

- Subject Matter: Manual clutch

- Vehicle Applications: General Motors

- Issue: Bleeding slave cylinder

If you have been installing clutches for a while, you are probably familiar with the dreaded Ford Ranger concentric slave cylinder and the difficulties and uncertainty presented when you’re attempting to bleed it.

Unfortunately, General Motors has followed suit with similar concentric slave cylinders. Most General Motors vehicle designs do not provide access to the slave cylinder without separating the transmission from the engine. Additionally, some models do not have bleed ports.

To assist with bleeding these problematic slaves, the following steps detail the proper procedure to bleed the system correctly while the transmission is off the vehicle.***

Step 1: Verify that the clutch master cylinder has a full fluid fill. If not, add additional fluid until full.

Step 2: Ensure that the clutch master cylinder is mounted level on the firewall. Some vehicles may require the master cylinder to be unbolted, leveled and reattached to the firewall.

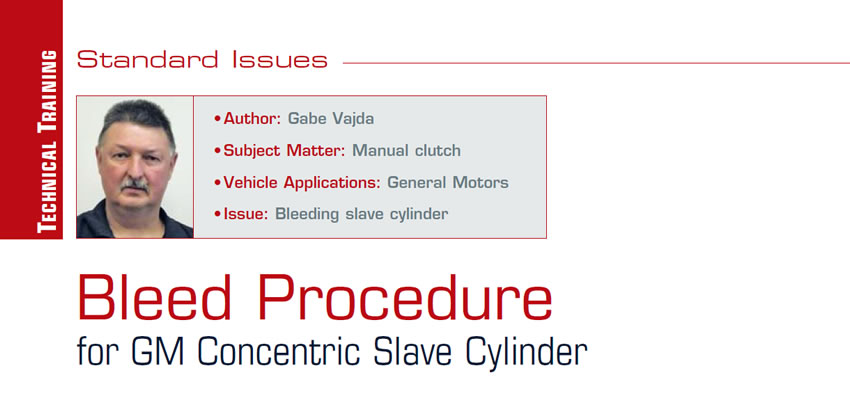

Step 3: Install the concentric slave cylinder on the transmission. Note: Some slave cylinders have the input-shaft seal built in (Figure 1). This seal MUST be lubricated! Failure to lubricate will result in seal damage and leakage.

Step 4: Lift the transmission up into the vehicle but do not mount the transmission to the engine. With the transmission lifted, reach up and connect the hydraulic line to the slave cylinder.

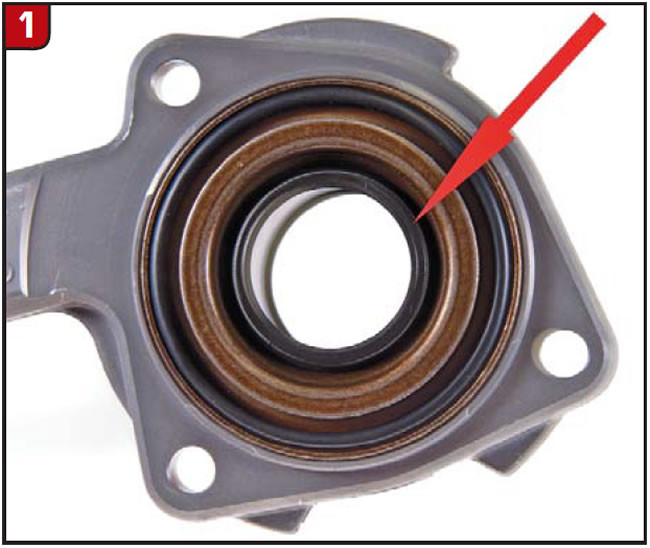

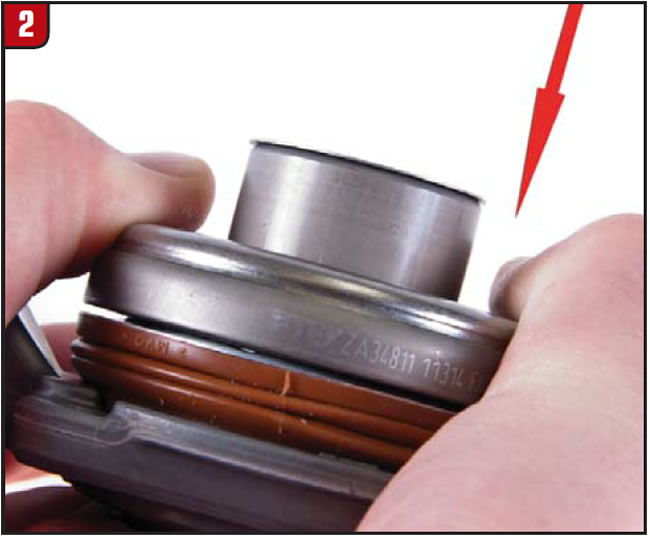

Step 5: Once the slave and hydraulic line are connected, reach into the bellhousing and push the slave cylinder back in its bore (Figure 2), then release and let it return to its original position (Figure 3). Repeat this process 12–15 times. Following this procedure will force any air trapped in the hydraulic line back up through the master cylinder, through its vent cap and out of the system.

Bleed complete.

*** This procedure will work on ANY vehicle with a concentric slave cylinder. It is the ONLY way to bleed many newer applications that do not have bleeder valves.

Gabe Vajda, ASE certified technician, is a technical-support engineer for the LuK, FAG and INA product lines of Schaeffler Group USA Inc.