Shift Pointers

- Author: Pete Luban, ATSG Technical Supervisor

The answer, of course, is “When it’s an automatic.” I’m often asked, “Where is the transmission business going?” With new CVTs, hybrid vehicles and the advent of fuel-cell-powered vehicles in the not-too-distant future, transmission shops are wondering what the future of the business will hold for them. Well, I wouldn’t worry too much. There are still plenty of new automatics coming out every year, although most of them are imports. But just in case you’re worried about clutch plates being removed from automatics, clutch plates are being added to manual transmissions to give them automatic-shift capabilities.

Which brings us to the meat of this article, which is BorgWarner’s DualTronic™ six-speed transmission, otherwise known as a DSG (direct shifting gearbox) or AMT (automated manual transmission), which was adopted by Volkswagen and Audi when the VW Golf R32 and the Audi TT 3.2 made their debuts.

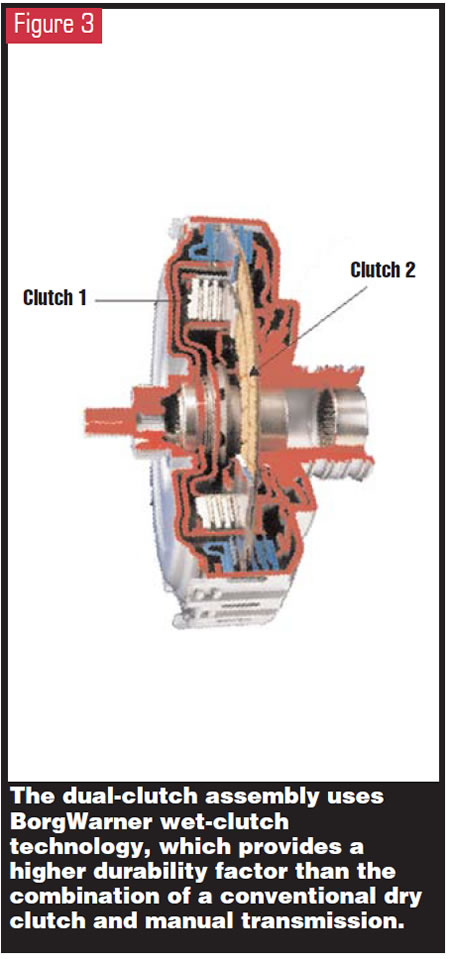

This manual six-speed transmission that can be shifted automatically or can be shifted manually when you’re in a sporting mood is a result of BorgWarner’s wet-clutch technology and its experience with electro-hydraulic control.

A couple of its strong points are much-improved fuel economy and the ability to virtually eliminate the interruption of power normally associated with manual gear changes.

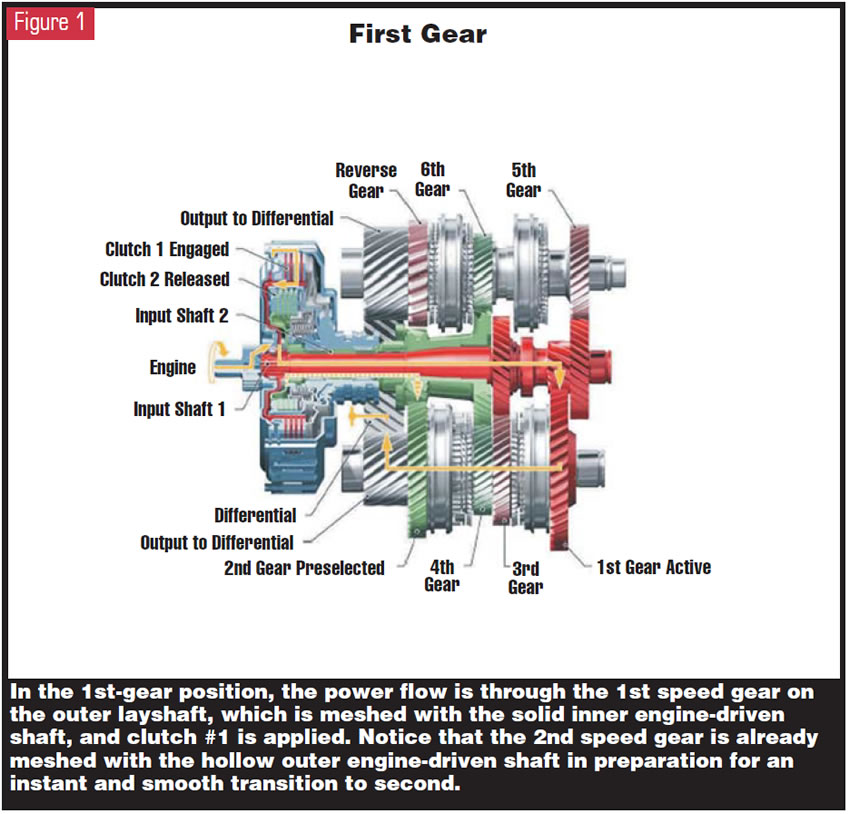

OK, now let’s get to how it works. The DualTronic system is based on a modified manual gearbox with six forward speeds. The transmission uses what is called a layshaft design. To better understand this concept, refer to Figure 1. The center shafts (there are two), which are driven by the engine, mesh with the two outer shafts, allowing the gearbox to attain its six forward speeds and reverse while keeping the transmission’s architecture in a smaller package than a conventional six-speed manual transmission.

The solid inner engine-driven shaft drives the odd-numbered gears and reverse, and the hollow outer engine-driven shaft drives all the even-numbered gears.

Each of the engine-driven shafts transmits torque via a hydraulic clutch pack. Which of the engine driven shafts is providing output torque depends on which gear is selected.

The illustration in Figure 1 shows the DualTronic in the first-gear position. Notice the power flow through the meshed gears and how the first gear on the outer layshaft is engaged with the solid inner engine-driven shaft. Clutch pack #1 is engaged while clutch pack #2 is released.

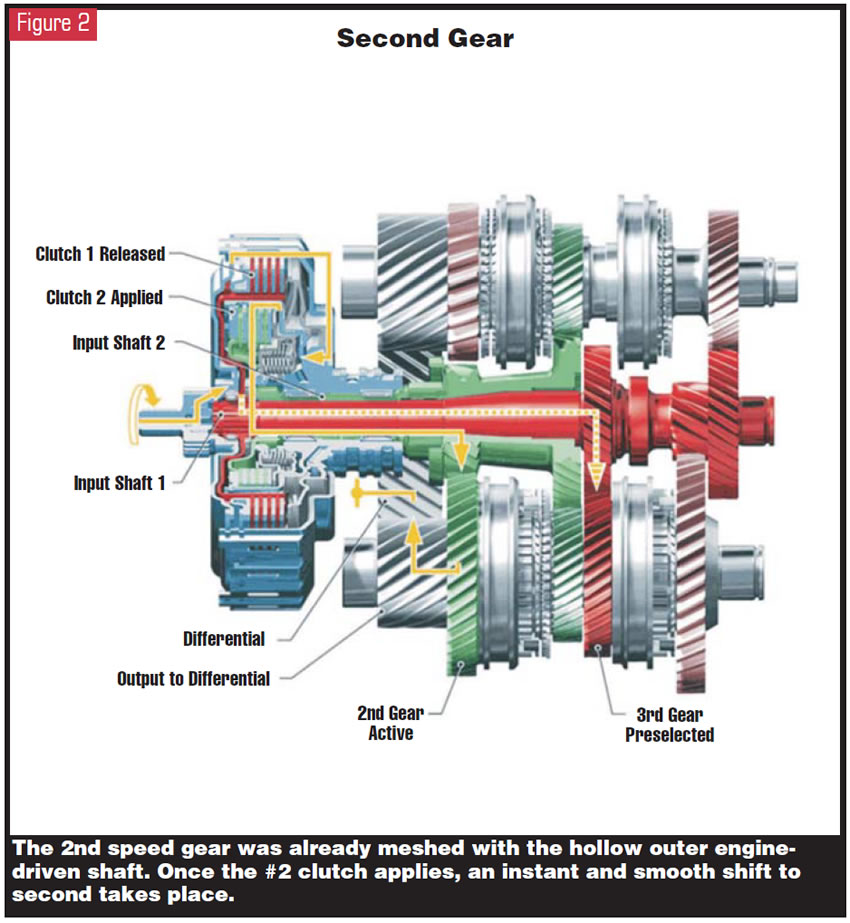

When a shift to second is made (see Figure 2), clutch pack #1 will release and clutch pack #2 will apply. Because second speed gear is already meshed with the hollow outer engine-driven layshaft, we have second gear the moment clutch pack #2 is applied. This allows for virtually no power interruption during the gear change. The remainder of the gear shifts operate similarly. Figure 3 shows the multiple-clutch-pack assembly.

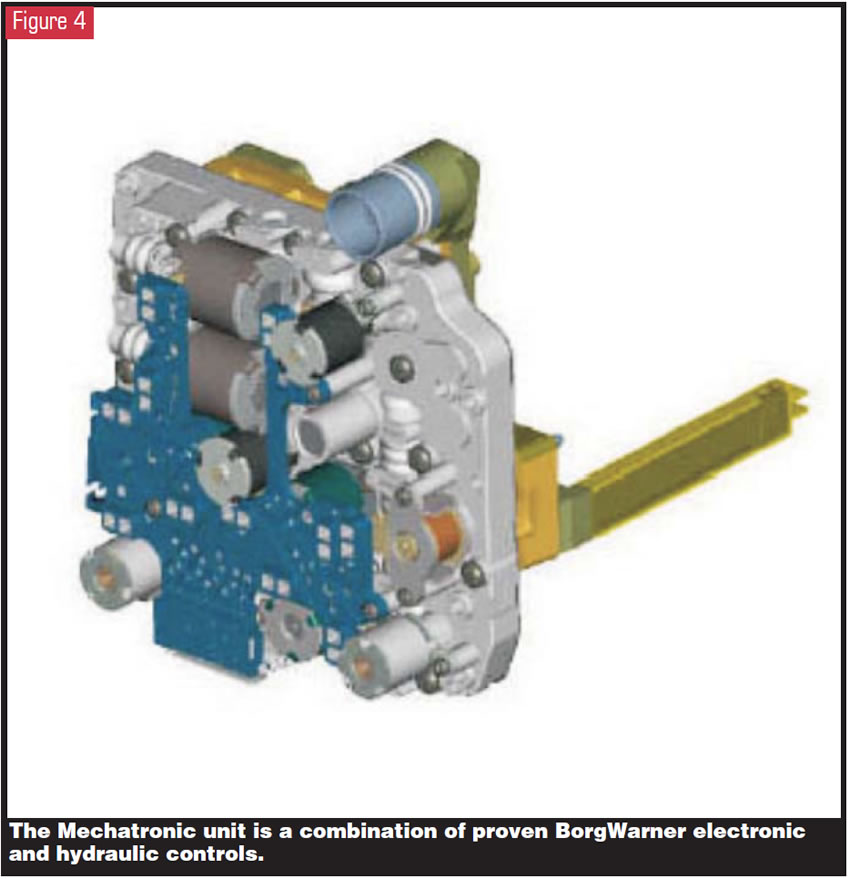

So, how does the DualTronic know which gear to shift to and when? Electronics; no, make that “Mechatronics.” The computer that controls the DualTronic is called the “Mechatronic” module (see Figure 4).

This module is positioned at the top of the gearbox, immersed in oil. Basically, we have a valve body and solenoids combined with an electronic control module, all rolled into one. The module receives input information from 12 sensors.

The “Mechatronic” control module coupled with the electro-hydraulics operates the shift-selector-fork assemblies as well as the multi-clutch solenoids and valves as part of the shift-control management.

In the automatic position, the driver can shift from the “Drive” position to the “S,” or Sport Mode, position. This action will delay upshifts and speed the downshifts.

When the transmission is in the “Manual Mode,” there is a special gate for the selector lever, and there also are “paddles” mounted on the steering column to manually shift the transmission when you’re in a Gran Prix mood.

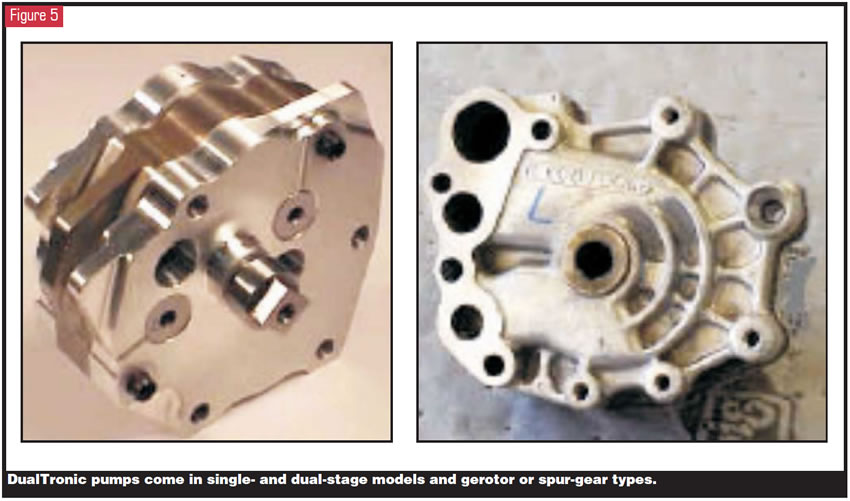

The DualTronic is available with different-style pumps depending on vehicle application (refer to Figure 5). It can have a single- or dual-stage pump, and the gears can be the gerotor or spur type.

The synchronizers are BorgWarner’s composite-friction design, which helps the mechanical part of the transmission operate smoothly under all conditions. They are the same design as found in other manual transmissions using the BorgWarner composite-friction synchronizers.

Well, there you have it, something new to look forward to. As I find out more about the DualTronic, I’ll pass it on to all of you. Gee, it’s an automatic and a stick; maybe you can get twice the money.

My sincere thanks to Dale Strepina, operations manager of BorgWarner Transmission Distribution Center, and Joerg Nitsche, BorgWarner Dual Clutch Transmission Program manager, for providing key information to make this article possible.