Jason Morgan is the editor of Fleet Equipment (Transmission Digest’s sister publication). He recently wrote about the state of the heavy-duty transmission market as it pertains to fleet operators.

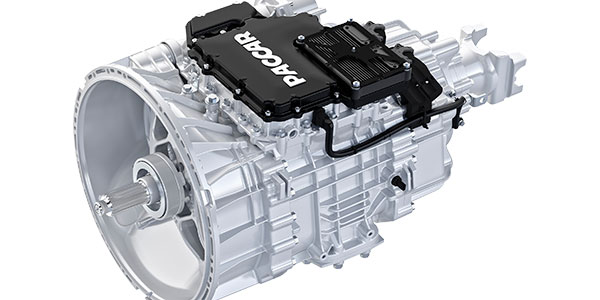

He says that the automated manual transmission (AMT) and automatic transmission manufacturers are crushing assumptions and setting new expectations in all trucking industry applications. Automatic transmissions are getting smarter and, in the AMT world, gone are the days of clunky, reverse-engineered AMTs. Today’s AMTs are, as PACCAR Vice President Landon Sproull put it, “purpose-built.”

“The gearing—overall ratio and step sizes—are suited for the job, and the gearbox architecture is right-sized as compared to preceding product platforms,” he said. “The previous AMTs were converted versions of manual transmissions.”

“Today’s automated transmissions are smarter, lighter, more efficient, more reliable and have longer maintenance intervals than ever before,” agreed Charles Ganske, product planning leader for Eaton Cummins Automated Transmission Technologies. “Fleets benefit from all these areas through fuel savings, maintenance costs and improved driver satisfaction.”

Fleet Equipment asked the top truck transmission manufacturers to prove it by rattling off some of the latest equipment evolutions.

Click here to read the full article.