Issue Summary:

- After rebuild, 4R44/55E and 5R55E units may exhibit delayed engagement when hot.

- Some full-size GM four-wheel-drive trucks may experience a “Service 4WD” indicator light that remains on.

- After replacement of the turbine-speed sensor, Ford/Mazda CD4Es may experience a persistent gear-ratio error.

- In Daewoo Lanos, Nubira and Leganza, there may be a variety of drivability complaints after repairs.

- Technicians may encounter difficulty removing torque-converter bolts in some GM units.

- Using the factory-specified fluid is essential with ZF automatic transmissions.

- Driveline vibration may occur under certain condi-tions in 2000-model GM trucks with a 4L60-E.

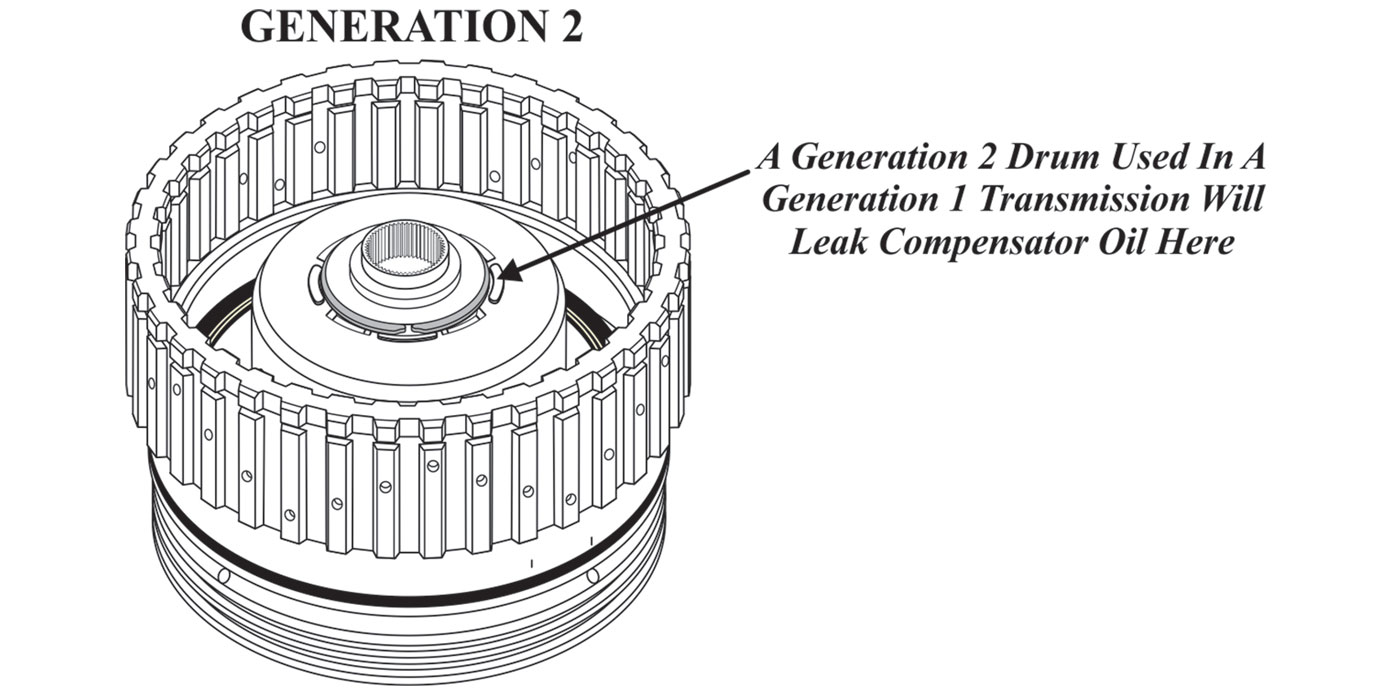

After a rebuild, the vehicle exhibits a delayed engagement when hot. Other symptoms that can accompany this concern include soft or flared upshifts, particularly the 2-3 shift on 4R units and 3-4 shifts on 5R units. Common building practices such as replacing the pressure-regulator valve spring with an A4LD yellow spring, tweaking the EPC solenoid 1⁄8 turn in and eliminating the engagement-control-valve spring have not solved the problem.

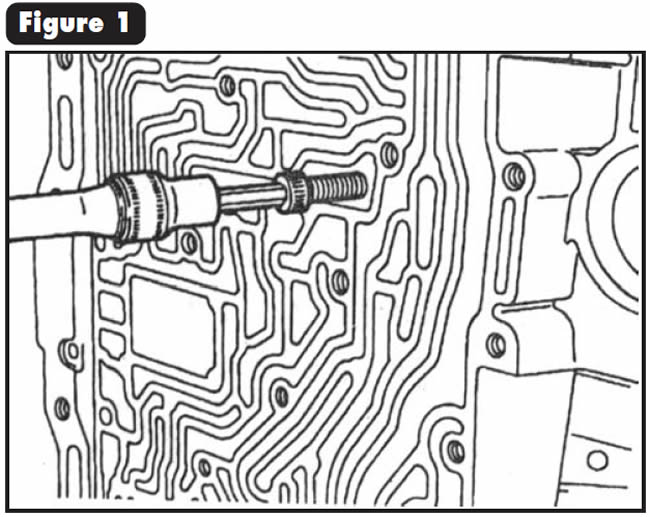

During rebuild, the rebuilder overlooked the center-support bolt and did not tighten it, causing a loss of clutch apply pressure (see Figure 1). If you install a line gauge on the unit, you may observe a sluggish line rise, with base line pressure being 10-20 pounds lower than factory specifications.

Tighten the anchor bolt with a 5mm allen wrench to 80-115 lb.-in.

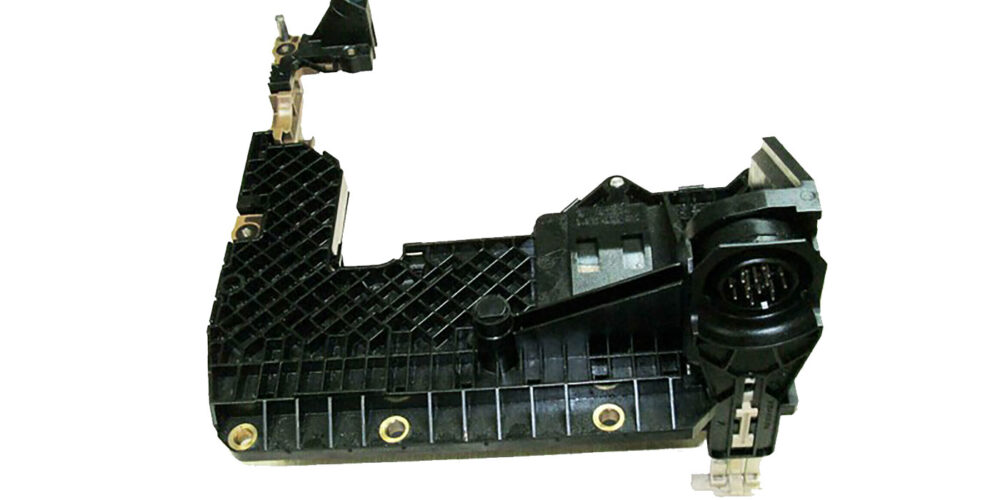

1999-2002 full-size four-wheel-drive trucks with a New Venture Gear 236/246 transfer case (RPO NP8) may experience a “Service 4WD” indicator light that remains on. A service code B2725 – ATC mode switch circuit malfunction – may accompany this concern.

An intermittent fault in the transfer-case select switch may be causing this condition. You should not immediately suspect or replace the transfer-case control module unless it has been determined to be faulty.

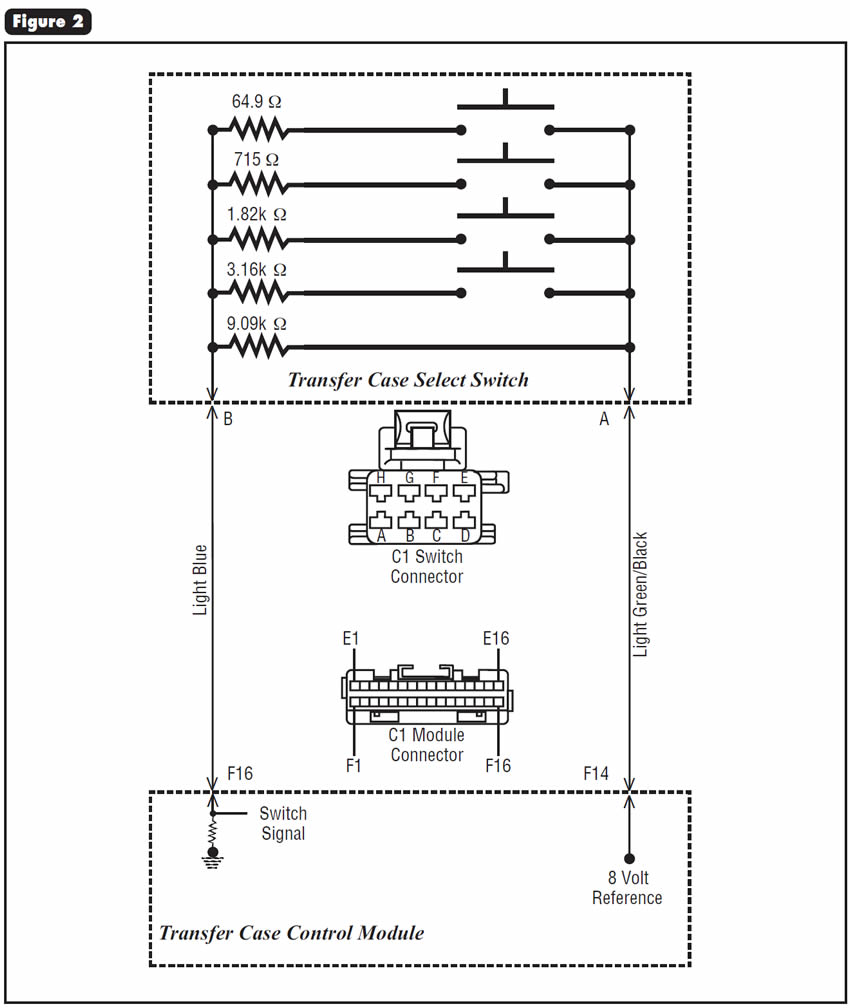

The transfer-case select switch (push button) contains four normally open switches (see Figure 2). It is in the center of the instrument panel, to the right of the steering-column shift lever. The driver uses this switch to select the desired transfer-case operation. The switch selection sends the appropriate signal to the transfer-case control module, left of the instrument cluster behind the headlamp switch. This module provides an 8-volt reference to the switch’s C1 connector at terminal A. If no buttons are pressed, the switch sends back to the module a 0.5- to 1.0-volt signal in its C1 connector at terminal F16. Should the module detect a voltage level outside of this range for longer than 5 minutes, the module will set code B2725. Simultaneously, the module will ground the wire at terminal E2 in its C1 connector, illuminating the “Service 4WD” light in the instrument cluster.

Replace the transfer-case select switch, part number 15709327.

The transfer-case control module should not need to be replaced. The part number for the module is 15749703.

After replacement of the turbine-speed sensor (TSS), torque-converter-clutch (TCC) slip code 628 or P1744 may be stored. One or more of the gear-ratio-error codes 628, 642, 645, 646, 647, 648, P0731, P0732, P0733, P0734, P0741 and P1744 also may be stored. After you clear these codes, they immediately return during the road test.

No matter which parts you replace or which procedure you follow, these codes keep returning.

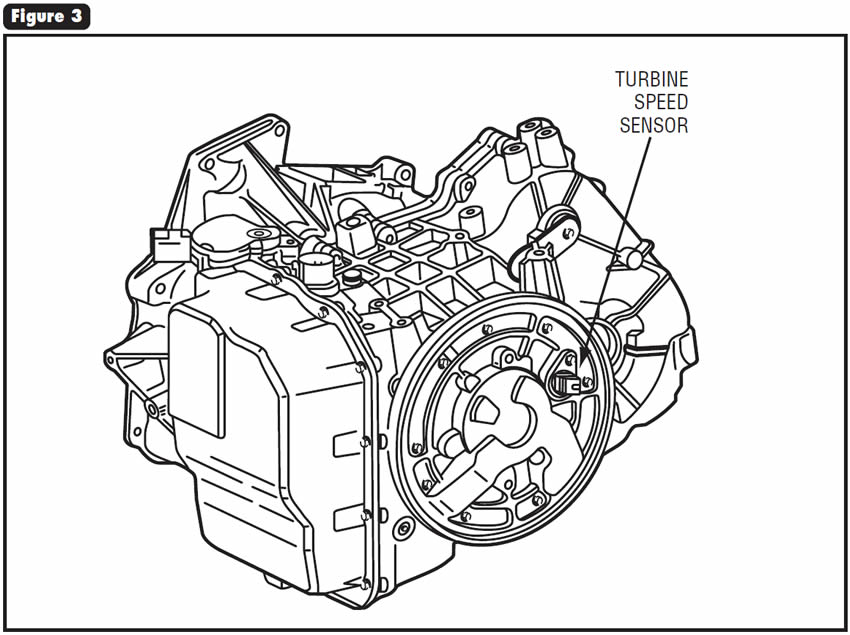

The cause, believe it or not, is the replacement TSS (see Figure 3 for location of sensor).

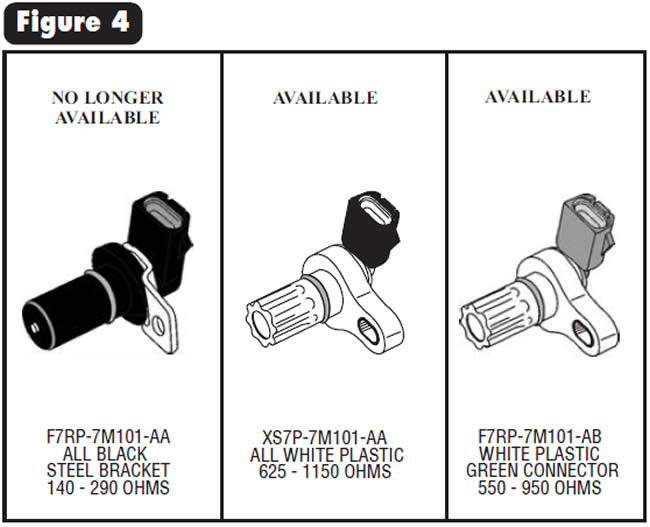

The replacement TSS was redesigned and has an enclosed pickup (see Figure 4).

It seems that when the pickup was enclosed, the air gap between the TSS and the reverse-clutch hub was increased. When the signal is checked and compared with that of the previous sensor, the new sensor exhibits a voltage difference. However, when checked with an oscilloscope, the previous sensor puts out a wider pattern than the current-design sensor, which means that the computer has more time to read the signal with the previous-design sensor.

In other words, with the current-design TSS on some models, the computer does not have enough time to read the signal and may miss alternate signal pulses, which causes the complaint mentioned.

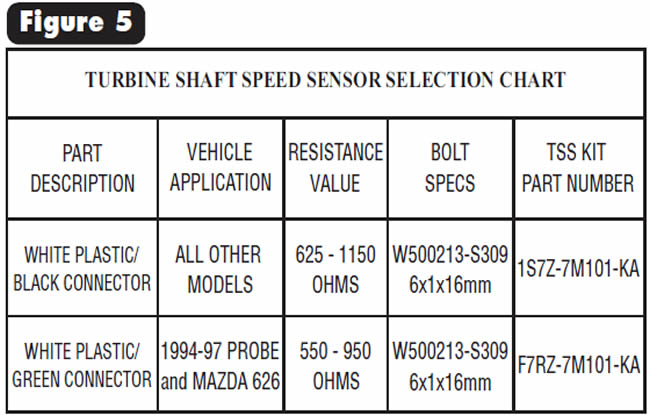

Ford Motor Co. has released a new-design white TSS with a green connector that is to be used on 1994-1997 Probe vehicles (see Figure 4). The new-design white TSS with the black connector is to be used on all other models with the CD4E transaxle. The first-design all-black TSS shown in Figure 4 is no longer available.

Install the proper TSS for the model that you are working on. Service part numbers are shown here and in the chart in Figure 5.

- Turbine-shaft-speed sensor, 1994-1997 Probe and Mazda 626, green connector . . . .F7RZ-7M101-KA

- Turbine-shaft-speed sensor, all other models, black connector . . . . . . . . . . . . . 1S7Z-7M101-KA

After repairs, the vehicle may exhibit a variety of drivability complaints. The malfunction indicator light may be illuminated with a variety of diagnostic trouble codes stored in the computer’s memory, including P1336 – “58x Crank Tooth Not Learned.”

Whenever any component that may affect the relationship between the camshaft-position sensor and the crankshaft-position sensor is removed or replaced, such as the sensors themselves or the engine control module/powertrain control module, or the battery is disconnected or replaced, poor drivability and various unrelated DTCs occur.

The dealer must perform a “crankshaft-position variation learning procedure” with its Scan 100 tool. This procedure (the TEC test procedure) electronically aligns the crankshaft position sensor to the camshaft position sensor to correct for variations in timing belt length, camshaft and crankshaft pulleys.

Sometimes when removing the internal allen slot-style torque-converter bolts, the technician may find them difficult to remove and possibly round them out in the process.

GM has released a new-style bolt with an internal/external hex-head design to replace the previous design.

- Part #1151921

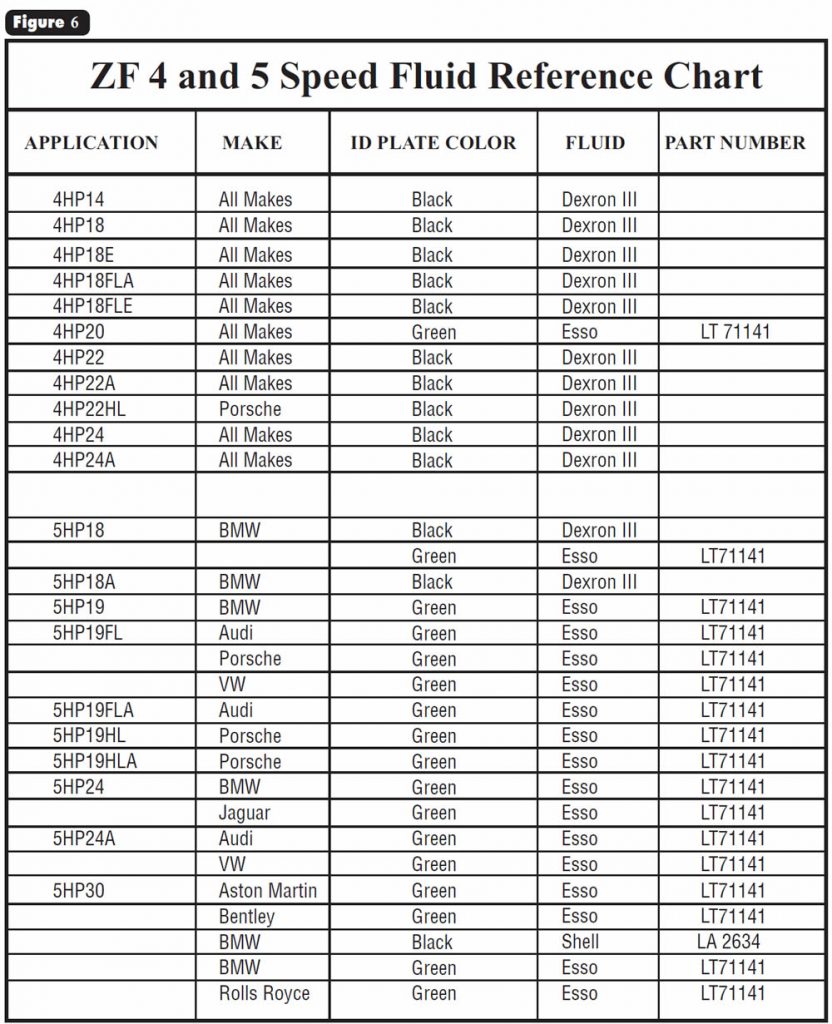

ZF Industries recommends specific fluid for its automatic transmissions. If an incorrect fluid is used, the bonding agent that holds the friction material to the backing plates may deteriorate. The converter clutch is most prone to this negative reaction. You can easily determine the fluid recommendation by the color of the transmission’s identification tag. The chart in Figure 6 lists the manufacturer’s fluid specifications for each unit to help you in selecting the correct fluid.

When looking at this chart you will notice that Shell fluid is used for only one application. We have noted that if the 5 HP 30 with black identification tag has been rebuilt with new clutches and is being installed with a rebuilt torque converter and all the clutches are dry, you can use Esso fluid LT71141 in place of the Shell fluid without any negative results. Mixing Esso and Shell fluid in any application is not recommended.

- ZF’s part number for a 20-liter container of Shell fluid is 0671 090 149.

- ZF’s part number for a 20-liter container of Esso fluid is 0671 090 166.

You can buy the Esso or Shell fluid through a ZF authorized distributor. To find a distributor near you, you can visit ZF’s Passenger Car/Transmissions Distributor Locator on the Web at

http://www.zf-group.com/am/pc/pt/ampcpt06.phtml or call 1-800-660-2269.

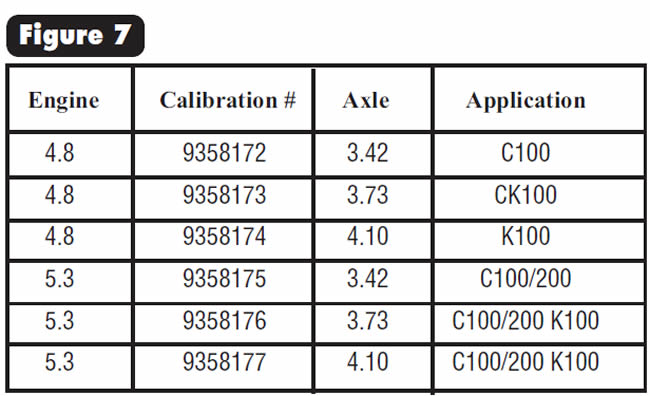

In 2000-model trucks with a 4L60-E behind either a 4.8- or 5.3-liter engine, a driveline vibration may occur at speeds between 35 and 50 mph during conditions of low engine speed with the driver’s foot off the accelerator.

Having the torque-converter clutch applied at low engine speed (100-1,400) transfers engine torsional vibration into the drivetrain, resulting in noises and vibration that the driver can either hear or feel.

Verify the vehicle year. On a 2000 model, Y is the 10th digit of the VIN. Next, verify the engine size by the VIN’s 8th digit. V indicates a 4.8-liter with RPO code LR4. T indicates a 5.3-liter with RPO code LM7. These codes are on the driver side of the engine block below the cylinder head. Once you have verified this, you will need to reprogram the vehicle’s PCM. Refer to the chart in Figure 7 for the appropriate calibration number.

Special Note:

On any ECC application requiring the torque converter to contain the woven-carbon clutch, be sure to use this style of clutch. Kevlar, cellulose or any other clutch material except the woven carbon used by General Motors will not live in this environment and also may cause driveline vibration before it fails.

September 2002 Issue

Volume 19, No. 9

- 4R44/55E and 5R55E: Delayed Engagement When Hot

- 1999-2002 Full-Size 4WD GM Trucks: ‘Service 4WD’ Indicator Illuminated

- Ford/Mazda CD4E: Persistent Codes for Gear-Ratio Error or TCC Slip

- Daewoo Lanos, Nubira and Leganza: Code P1336 – 58x Crank Tooth Not Learned

- ZF Automatic Transmissions: Information on Factory-Designated Fluid

- 4L60-E: Driveline Vibration