Shift Pointers

- Author: Jim Dial, ATSG, Senior Technical Consultant

Have you ever wondered where those extra O-rings go that are left over in the kit bag after you’ve completed an overhaul on a transmission? Most rebuilders, including myself, will twist-tie them to a bellhousing bolt hole and say, “Must be some spare pieces for the R&R guy!”

A couple of months ago Wayne Colonna went into detail on a concern that was commonly overlooked on the 4L80-E: problems with the No. 7 and 11 checkball capsules in the valve body (Technically Speaking®, September 2005). Many times those capsules would not get cleaned thoroughly, and that could cause either a slip in reverse or no reverse. He also talked about the sleeve for the No. 11 ball capsule and the O-ring at the end closer to the 3-4 shift valve and how hardening of this O-ring would cause leaks in the actuator-feed-limit circuit, resulting in a 3-4 neutral when the transmission was hot. Many technicians did not even know that there was an O-ring in that location!

This article is about a similar situation. This time it pertains to the 4T65-E and a complaint of a torque-converter-clutch (TCC) surging sensation between 40 and 60 mph and/or a P0741 diagnostic trouble code before or after overhaul. This complaint seems to be more prevalent on 2000-and-up models. The scenario goes like this: While you’re driving the vehicle between 45 and 50 mph, TCC slip bounces from 175 rpm down to 50 rpm, back up to 150 rpm and back down to 35 rpm. The TCC-slip speed seems to come down to about 25 rpm around 60 mph, although the slip speed will begin to go up again when the vehicle begins to climb a small grade.

We notice when monitoring the duty cycle for the TCC PWM solenoid that the duty cycle seems to be lower than on other models that we have road tested and that it seems to cap out around 60%-68% at 60 mph, whereas previous models would cap out around 75%. This lower duty cycle seems to send many technicians down the wrong road, the road full of computer reflashes and engine-load-device repair and/or costly replacement. You guessed it – this is a normal duty-cycle percentage; what is abnormal is the slip amount. TCC slip should be between 0 and 20 rpm at 60%-68% duty cycle.

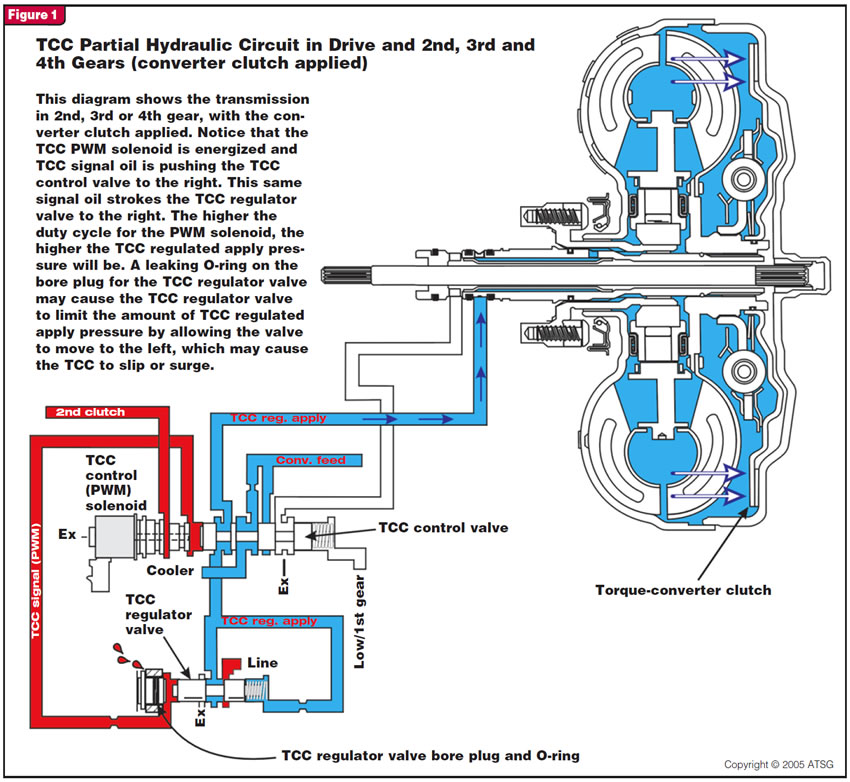

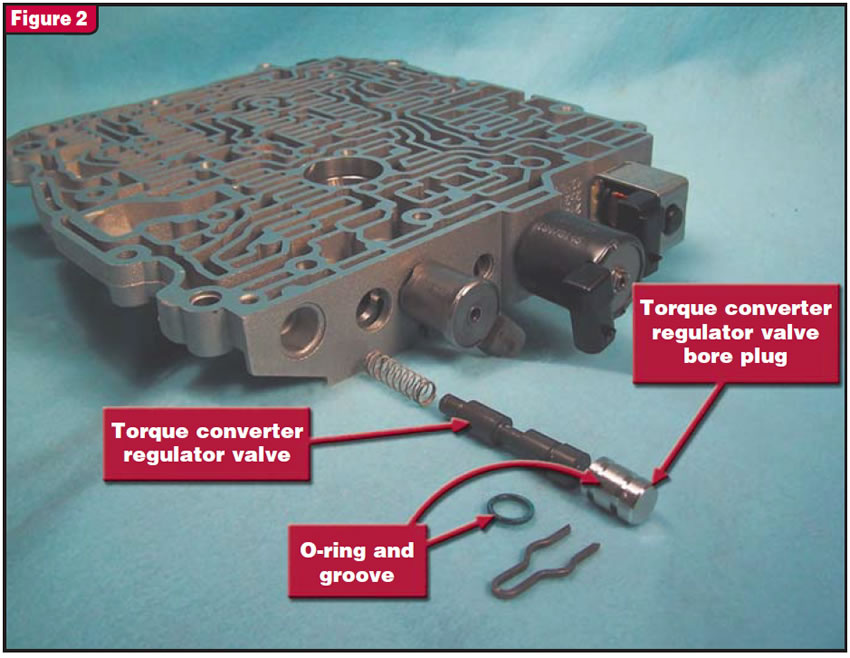

The root cause of this problem is, of course, again related to the converter regulator valve but in this situation may not be a wear-out condition as in the 4L60-E. Figure 1 shows a partial hydraulic schematic of the TCC apply circuit. Notice that the TCC-regulator-valve line-up has a bore plug with an O-ring. This O-ring , also shown in Figure 2, when rock hard can cause a significant pressure loss in the TCC-signal circuit. (For those of you with valve-body testers, this O-ring also can cause the dreaded “red ATF underwear.”)

This, in turn, is what creates the surging sensation. The loss of pressure in the TCC-signal circuit and lower duty cycle for the TCC PWM solenoid allow the TCC regulator valve to move to the left, causing insufficient TCC apply pressure, which may cause engine surging or a DTC P0741 (TCC stuck off). This also may answer the question, “Where does this O-ring that is left over in the kit bag go?”

I hope this will help you in your diagnosis on 4T65-E TCC problems, and we are hoping to see all of you in the 2006 seminar. I thank Jim Blatt of Lee Miles for enlightening us on this problem.