Mike Pfau has spent his entire career working at Jasper Engines and Transmissions where he currently is advertising manager. Pfau is meeting with Transmission Digest when he observes that the company, while one of the first production rebuilders continues to rely on innovation and new processes, most of which are generated from within the company itself.

“We’ve been doing what we do for a very long time,” explains Pfau. “Next year we celebrate our 75th anniversary. Change, for Jasper, is a constant. Our CEO, Doug Bawel talks about the five points that guide everything we do: safety (always first), quality, productivity, customer service and reduction of waste. Within those guidelines lies our focus and dedication to continuous improvement.

“We are ever moving forward; anybody standing still is actually falling behind. Our system fields more than 17,000 continuous improvement ideas submitted annually by our associates. We actually implement 86% of those; something in excess of 14,000 a year. Most are small things that result in incremental improvement. Those types of ideas are evaluated and acted upon by a group leader or division manager within our facilities. On the other hand, there are some very large ideas that are saving us thousands of dollars a year. One or two of those large ideas can easily pay for the cost of keeping a program of continuous improvement going.

“We are constantly adapting or adopting procedures that will improve our productivity, hold the line on cost, and by application of those procedures we increase the overall value to the customer.”

Until last year transmissions and engines shared what was known as the main building or factory where the corporate offices are located. A facility no longer used by another Jasper (Indiana) company was acquired and completely renovated, which led to the opening of the Power Drive plant. All main plant transmission, and differential operations have been moved to this new location. Sara Schmidt is the division manager overseeing transmission work at Power Drive where 220 Jasper associates remanufacture between 170 and 180 transmissions a day.

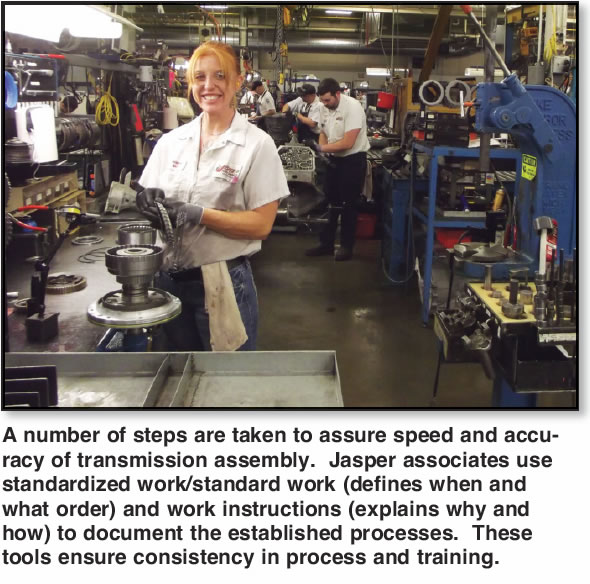

“Until recently, we developed the work areas that we call pods into smaller spaces with the idea that we didn’t need to travel as far to complete the necessary processes within a given pod,” explains Schmidt. “These traditional pods are staffed with up to six associates. What we learned is that at some point you end up creating ‘cockpits’ so that getting help or training to an associate in those tight quarters was very difficult, often resulting in stopping or slowing work of the entire pod. We actually found ourselves losing units that should have been completed.

Schmidt also explains that some of the work areas are being redesigned in order to meet a growing demand on specific units. “Here in the Power Drive facility we installed two megapods for high-volume transmissions like the 4L80E and E4OD/4R100 units.”

“A megapod is staffed by approximately 20 associates and what we found after expanding the space in those pods was that a “U” shaped design takes a little more floor space but is safer ergonomically, aids in better training, gives us better visibility to identify slowdowns or problems and a lot more flexibility as the space between the individual work stations is just enough so that we can deal with those situations. For instance, if we see the associate is having problems with getting proper clutch clearance and is falling behind, a team leader may step in to take the clutch problem so that that the associate can start on his/her next unit with the rest of the pod, which will maintain our remanufacturing quantity goal.”

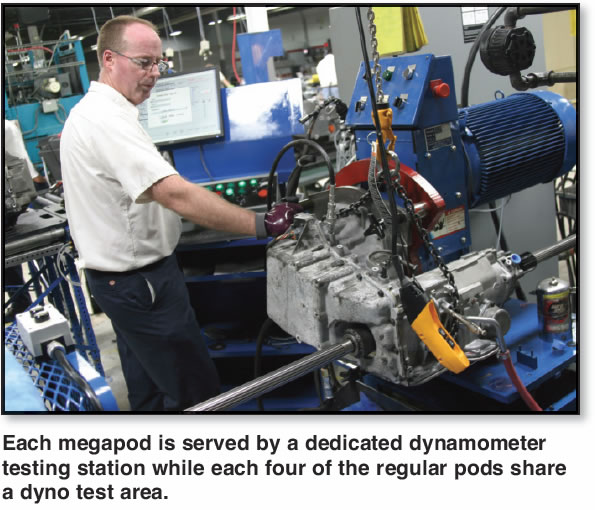

Schmidt continues to point to improvements implemented at Power Drive saying, “We found that having a dedicated area for dyno testing wasn’t an efficient use of time and created a lot of movement around the floor. We now have a dynamometer located and shared between four of the remanufacturing pods; one dedicated for each of the megapods. Each dyno has an operator who is able to share very near real-time feedback to the pods.

“We have also installed a 100-horsepower washer. That is an absolute tank! Units run through there as they’re entering the facility where we remove grease, oil, grime, etc., before we start work. That means as we start the disassembly processes we don’t have to chisel the gunk off of the bolt heads and, in general, we can see what we’re doing much better. This has cut our case blasting time by half. Of course, we’re still cleaning the internal components in the same manner we always have.”

At the Crawford County facility located about 40 miles east of Jasper, Joe Haug serves in the same division manager role as does Schmidt at Power Drive. Haug explains his operations saying, “We are building 127 units a day here. Before the Ford E4OD/4R100 megapod was relocated, we’d been averaging between 145 and 150. That move should make room for continued growth of this facility’s 4R70W and the 6L80E and 6L90E units that gradually will replace the 4L60 and 4L80 in popularity. Those GM four-speeds account for nearly 70 units a day, almost half of our total output, so you can see why we had to relocate some of the lines elsewhere. We were out of space to keep pace. We need to be able to have those six-speeds ready and available in inventory. If we don’t have that and a customer finds it somewhere else, we might not get that customer back.”

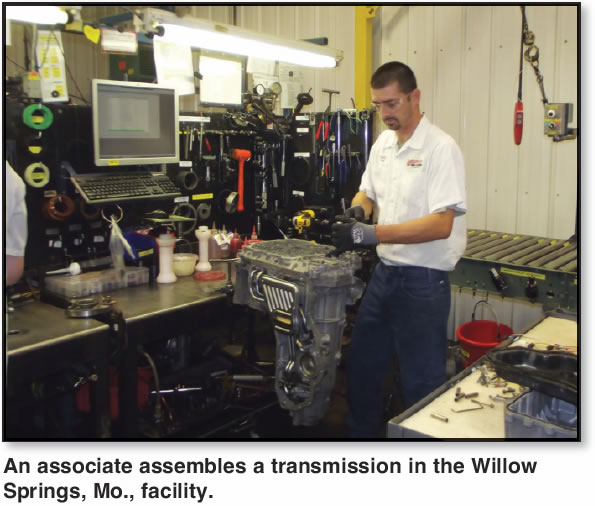

A third automotive transmission remanufacturing facility is located in Willow Springs, Mo., and recently was expanded by more than 30,000 square feet. Josh Piland, transmission division manager at that facility, says the expansion included 5 new docks, 18,000 square feet of added mezzanine to accommodate new parts inventory and a 13,000 square foot expansion of core warehouse capacity for engine and transmission cores. The facility and its associates are responsible for 14 different applications, adding 40 transmissions a day to the company’s total volume.

Schmidt goes on to say that maintaining the correct parts at assembly has always been a challenge as, for instance, a 4L80 unit may have one of two shift shafts. Jasper addresses those issues by having sub-assemblers in every pod tasked with stacking the proper clutches in the proper order and laying out parts for each unit.

Explaining in detail, she says, “In putting together the parts on the presentation board, anything that’s been scrapped is replaced. There’s a quick visual that allows the assembler to identify that all parts are present and there’s a quality aspect as well.

“Within the pods we want to test anything we can before the unit is completely assembled and sent to the dynamometer. Whatever we can discover within the pods is going to be much easier and less time consuming to fix than something identified at dyno testing that will require another disassembly and reassembly. For instance, valve bodies are vacuum tested and solenoids are given the Answermatic oil test and some of the cases are leak tested.

“The drive for continuous improvement in our processes is something we do to create the very best product we can for our Jasper customers,” she told us.

“I think the people who install our units want – make that demand – quality while at the same time, they want value,” says Pfau. “We’ve all learned over the years that sometimes you can buy the cheapest, but then you’re not really happy with the results. Then you try something different and in the end, you spend more money than if you’d started with a quality product. Quality has to be part of the determination of value. People want their vehicles to last, and the people who work on those vehicles have done what they do enough to understand value.

“In 2010, Jasper Engines Transmissions became a 100% associate (employee) owned company, giving its associates the pride of ownership and a significant stake in the growth of the company. The company believes that progressive moves such as this will help to make sure that the Jasper brand, developed through the hard work and efforts of so many, will continue for years to come. I think this is an important component of the involvement every associate feels with the company.

“We’ve been doing this for a very long time and yet, as I said, we implemented in excess of 14,000 improvement ideas last year. We keep doing it better and better to live up to the expectations of quality, reliability and value that customers have come to associate with the name Jasper.”

Pfau concluded, “Our mission statement is simple: ‘Do It Right and Have Fun!’ We are committed to remain a leading force in the automotive industry. Our progressive programs of research and new product development enable us to provide quality value-oriented products second to none.”