We have all experienced repairs that seem to “go down the rabbit hole,” as we call it. Our subject today is one such issue: a Ford 6F35 transmission with codes P073D or P177F after repair and a complaint of trying to go into Reverse while in Neutral, or a bind in Forward when cold. This condition in varying degrees and codes may also be present before repair, so let’s explore what’s involved with this complaint.

OE code definitions

P073D and P177F both have the same definition: Unable to engage Neutral.

Component: Forward or direct clutch pack.

Condition: This DTC may set when there is a mechanical/hydraulic concern with the direct or forward clutch pack, possibly deformed clutch plates or a rolled clutch seal allowing the direct clutch or the forward clutch to apply in Neutral mechanically or hydraulically.

Basic test and verification

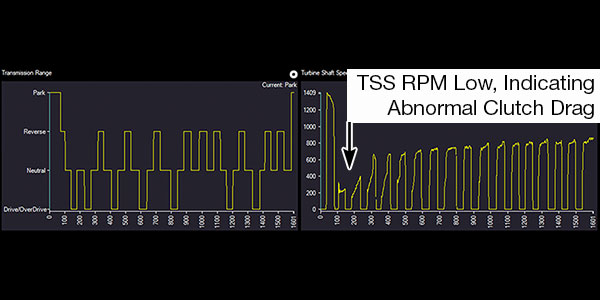

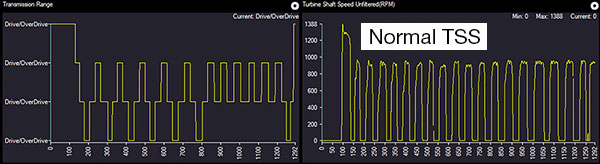

To verify this complaint, scan the vehicle and watch the turbine speed sensor (TSS) data parameter identification when changing the selector from Reverse and the drive range to Neutral. You are looking for TSS RPM that lags by 200 to 400 RPM or more below engine RPM when shifted into Neutral range, coinciding with the complaint as shown in Figure 1. Compare that with scan data indicating the correct behavior (Figure 2).

The repair process

Vehicles with Gen. 1 and 2 6F35 transmissions have been returning to dealers with this complaint under warranty since they were new. Typically, it is caused by delamination of 3-5-R, 4-5-6 clutch balance pistons or a clutch pack that is welded together. Usually, a repair is made and the vehicle is back on the road with no issue. The same scenario is played out in transmission shops, too, but the after-repair may not go as planned. For example, the vehicle may have come in for another complaint (such as the very common TCC failure) and did not originally have either code P073D or P177F. That is when you immediately think the repair must be at fault, but what could it be?

The repair process failure and the fix

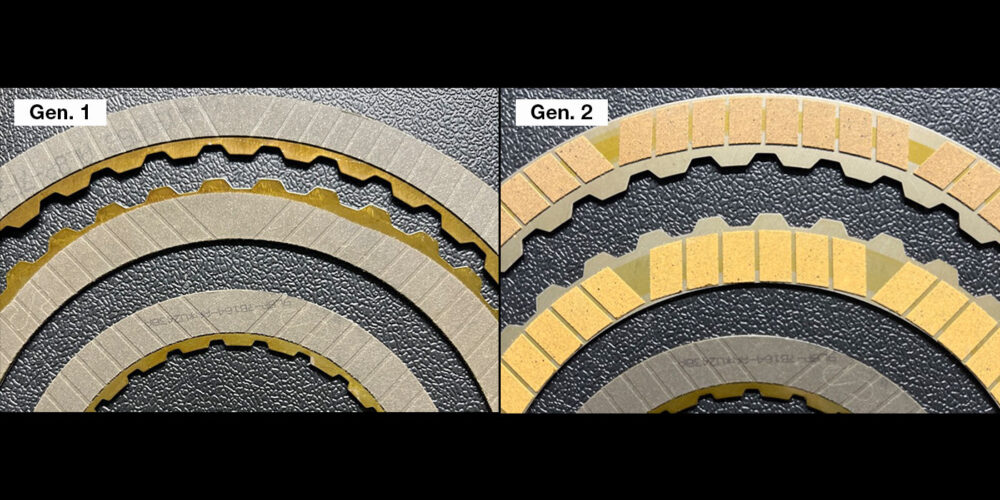

Not all “kit clutches” are the same. When you order a rebuild kit, even though you may specify OE clutches (Figure 3), you may not get them. The problem is some aftermarket clutches have too much drag or an excessively high coefficient of friction. Gen. 2 clutches work fine in Gen. 1 units—in fact, they are a great upgrade—but the 6F35 does not like certain aftermarket clutches.

OE clutch part numbers are:

- Gen. 2, 3-5-R clutch (3): CV6Z-7B164-D

- Gen. 2, 1-2-3-4 clutch (2): CV6Z-7B164-B

- Gen. 1 and 2, 4-5-6 clutch (5): 9L8Z-7B164-D

Read more columns from the TASC Force Tips series here.

To fix this complaint, use OE clutches and Mercon LV ATF along with OE molded pistons. If repairing a Gen. 2, make certain the 3-5-R/4-5-6 clutch tower bolted to the rear case has the updated bleed circuit at bottom for 3-5-R clutch.

See the Transmission Digest article titled “The subtle differences in repairing Ford 6F35 generations 1 and 2,” published in December 2021. This fix should be done before replacing valve bodies, rear case halves, TCMs and other internal parts. Proper diagnosis is a must on this unit.

Other issues may also occasionally cause this complaint, so let’s look at a few:

- If the valve body checkball is out of place or missing. ATRA has a Technical Bulletin (no. 1813) about this occurrence. This causes a severe bind in Reverse and Neutral movement with the 1-2-3-4 clutch applied.

- Solenoid failure can occur and cause similar symptoms; this will usually be evident with other complaints as well.

- A stuck compensator valve in the valve body can also contribute to this complaint. Diagnosis for that is a pressure test on compensator port rear of case.

- Replacing the rear case half has fixed a few units as reported on social media, but the jury is still out on this. If you suspect a problem with the rear case, heat it up and check the circuits with both shop air pressure and vacuum. In vehicle diagnosis, use gauge hoses with vice grips for on/off control to exhaust pressure in rear case circuits as needed for diagnosis (see Figure 4).

Thank you to James Gray, Phil Materi, Ray Clark and others who provided the data and information that made this article possible.

Jim Mobley is a Sonnax technical communication specialist. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.