November 2003 Issue

Issue Summary:

After re-installation, the transmission in a Nissan Quest/Mercury Villager is stuck in third gear, line pressure is at a maximum level and the inhibitor-switch circuits do not range correctly. Solenoid codes also may be present.

The Audi 01F/01K transaxle (ZF 4HP-18FLE/FLA) may have a vent cap mounted on top of the transmission filler tube instead of a dipstick.

In GM electronically controlled transmissions, false output signals can cause complaints including no TCC apply, wrong-gear start, missing gears, falling out of gear, or line-pressure control problems.

When removing the allen-style torque-converter bolts in 4L60-E and 4L80-E transmissions, a technician may find them difficult to remove and possibly round out the internal hex slots.

1999-2002 4WD trucks with a New Venture Gear 236/246 transfer case may experience a “Service 4WD” indicator light that remains on, possibly accompanied by Service Code B2725 (ATC Mode Switch Circuit Malfunction).

An electronically shifted GM transmission may exhibit late 2-3 and 3-4 shifts under heavy-throttle conditions but seem to operate properly under normal throttle conditions. It also may have an elongated forced detent shift with no increase in vehicle speed that may require the driver to back off the throttle to complete the shift.

No Vehicle-Speed Sensor?

A 1995 Lincoln Continental with an AX4N transmission comes into the shop with a gear-ratio-error code. As you are going through the diagnostic routine, you have pretty much determined that the unit needs to come out. But before you remove it, you decide to check for a glitch in the vehicle-speed sensor (VSS).

Getting Polished With Chrysler’s Buffer

The speed buffer in a GM vehicle (see Figure 1) is a familiar piece of hardware for most transmission technicians. And its operation of taking an AC voltage signal from a speed sensor and converting it to a DC pulse signal for the computer is just as familiar. But what does come as a surprise to many is that Chrysler uses a similar speed-signal strategy for many of its passenger cars and vans.

October 2003 Issue

Issue Summary:

General Motors electronic transmissions can experience a wide variety of complaints related to program parameters installed in the vehicle’s computer at the time of manufacture.

PCMs in some 1996 and 1997 Taurus and Sable models equipped with 3.0-liter 12-valve engines have been reprogrammed to eliminate complaints of engine surge or engine miss at vehicle speeds between 45 and 60 mph while the vehicle was still under factory warranty.

Before or after overhaul, 1995-2002 Ford Motor Co. vehicles equipped with 4R44E/55E or 5R44E/55E transmissions may exhibit soft or flared shifts and multiple gear-ratio errors.

It Ain’t Just Oil

One thing we have seen that is consistent in the repair industry has been an unprecedented explosion of new and changing technology. An amazing number of new transmission and transfer-case designs soon will be appearing in your shop. The ever-increasing use of computer and electronic controls has made all the units more sophisticated, and diagnosis is becoming a stand-alone specialty.

Problems With Metric Cooler-Line Fittings

Few things slow down an R&R job like frozen cooler-line fittings. The metric cooler-line fittings used in Isuzu 4L30 applications and Toyota trucks with A340/30-40LE (see Figure 1) are frustrating enough to make you want to reach for the tubing cutter and start cutting rather than struggle with stubborn lines.

I Hate Noises

By this time, I guess you’ve figured out that this article has to do with noise. I’m sure many of you reading this have your own noise-related horror stories. Noises are difficult to diagnose when you’re standing right there; on the phone, they’re next to impossible. (Have I mentioned that I hate noises?)

September 2003 Issue

Issue Summary:

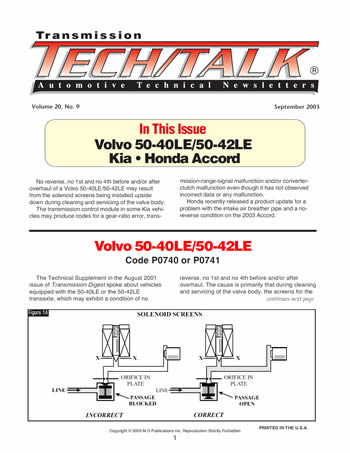

No reverse, no 1st and no 4th before and/or after overhaul of a Volvo 50-40LE/50-42LE may result from the solenoid screens being installed upside down during cleaning and servicing of the valve body.

The transmission control module in some Kia vehicles may produce codes for a gear-ratio error, transmission-range-signal malfunction and/or converter-clutch malfunction even though it has not observed incorrect data or any malfunction.

Honda recently released a product update for a problem with the intake air breather pipe and a no-reverse condition on the 2003 Accord.

Plumber’s Helper

This month’s problem/fix comes to us from overseas and concerns the ZF 5-HP-24 transmission. Although this problem has occurred primarily in Jaguars in this shop, it also could occur in other makes using this transmission.

Here is how the symptoms were described to me: The car comes in with a complaint of harsh upshifts and downshifts, no codes are stored, and the transmission is not in limp mode.

KM End-Clutch Failure

Have you ever noticed that most of the complaints or failures you have with a KM involve a burned end clutch? The complaints tend to be sliding 1-2, 2-3 spin-up, neutraling on the 3-4 shift, delayed engagements, no forward or no reverse.

I’ve seen every one of these complaints, only to find the end clutch burned. You might be thinking, “What does a burned end clutch have to do with a sliding 1-2 shift?”

Synchronization: A Study in Timing

Manual-shift transmissions have been manufactured with synchronized gear train for decades. The early designs were three-speed transmissions with 2nd and 3rd gears synchronized, and as transmission design progressed, four-, five- and six-speed transmissions were developed. At this point all forward speeds were commonly synchronized, and as the purchase costs of the vehicles increased and customers became more demanding, reverse was synchronized in most late-model vehicles. Synchronizers remain the most-misunderstood components in manual transmissions and transfer cases and therefore cause a great number of diagnostic headaches and comebacks.

Hot Tech From the Hotline

Have you ever encountered spin-out of the front pump bushing on a Mitsubishi KM unit as shown in Figure 1? Several years ago Paul Yaklin produced a bulletin explaining how the converter pilot bushing would get stuck on the pilot of the converter (see Figure 2). When the converter is removed, the pilot bushing stays with the converter unnoticed. Inevitably, a rebuilt converter then is installed without the adapter bushing in the crank bore. As a result, the centerline of the converter becomes seriously misaligned.