Up To Standards

- Author: Mike Weinberg, Contributing Editor

One thing we have seen that is consistent in the repair industry has been an unprecedented explosion of new and changing technology. An amazing number of new transmission and transfer-case designs soon will be appearing in your shop. The ever-increasing use of computer and electronic controls has made all the units more sophisticated, and diagnosis is becoming a stand-alone specialty.

On the manual-transmission and transfer-case side, there have been a wide variety of new synchronizer and clutch pack designs for improved shifting and smooth application of four-wheel drive systems. As can be expected there are now many new and different types of manual-transmission and transfer-case lubricants specified for use in these new designs.

Gone are the days when all you had to stock was 90-weight gear lube and ATF; in fact, there is almost no design left that will tolerate 90-weight gear lube except for a few older truck four-speed transmissions and rear differentials. Using the correct factory-specified fluid in the late-model stick transmissions and transfer cases is absolutely necessary for proper operation. A great many tech-line calls are generated by shops that just throw what they have into the gearbox they just spent a lot of time repairing, only to have poor-quality shifts and various noises.

If you consider that a synchronizer ring is a wet clutch, it is easy to see how the wrong fluid will create undesirable results. At one time, almost all synchronizer rings were made of bronze or brass and functioned using the heavier gear lubes of the period. Late-model designs use synchronizer rings that in many instances are a steel body lined with various types of paper, carbon fiber, sintered-metal compounds and various types of synthetics. There are also double and triple cone rings in the newer sophisticated gearboxes, and the timing of shifts must take into account the ability of the ring to exhaust the oil from the cone of the speed gear as it begins the shift cycle.

Another ugly problem that comes up with an incorrect lube is that these various synchronizer linings are porous and act as a sponge. Problems resulting from putting an incorrect lube into a unit will not be cured by just draining it and putting in the correct fluid. It may take several hundred miles of driving to get the ring linings to purge the wrong oil and begin to operate correctly. This is generally what you would call a tough sale to make to a customer who has just put a big dent in a credit card by paying your bill.

The discussion here is about using the correct factory-specified lube for your application and some suggested substitutes that can be used to improve transmission performance and durability. Do not experiment on your own unless you have the time and manpower to conduct research in a controlled environment or are in a last-ditch attempt to cure a problem and stay out of court. All the lube recommendations you see here have been made after testing and research that we have performed on countless gearboxes and transfer cases and have been proven to improve shift quality and increase durability over ten of thousands of miles.

Many units are specified to run on ATF, usually Dexron 3. This was started many years ago to eliminate cold-shift complaints on units that then were running 90-weight gear oil in cold climates. The transmissions were very difficult to shift until the lube warmed up.

There has been a lingering feeling in the trade that somehow ATF was not up to the job of running standard transmissions. This has always seemed strange to me, because if the repair industry had to test its finished product as the OEM manufacturers do, no shops could afford to be in business.

For instance, when the carmakers come up with a new synchro technology or a new transmission design, they usually order 2,000-plus pieces of the new design, build a number of units and proceed to shift them on test stands and on the road to destruction. When these parts have been made to last through hundreds of thousands of shift cycles and countless road miles and the design has been improved to the point of diminishing returns, the part will be validated for production use.

ATF and synthetic ATF are wonderful lubricants. They are the lube fill for virtually every automatic transmission and many standard gearboxes. The word synthetic gives the impression that these products are man made. Almost all lube oils are based on petroleum, with special additives combined to make the entire package suitable for the job intended. Synthetic describes the cracking process used to refine the crude oil and realign the molecular structure to improve on that created by Mother Nature. The main improvements that come with synthetic fluids are their inherent ability to handle higher temperatures without oxidation and breakdown of the additive package.

There are drawbacks to the use of ATF in certain units, and we will make recommendations where it is safe to substitute other types of lube. One problem associated with ATF is that under certain operating conditions it has the ability to form a mist and vent from the transmission or transfer case undetected. Most of these units are “splash” lubricated, which means that the action of the geartrain throwing the oil around inside the case is enough to lube and cool the unit adequately.

Certain units are known to lose fluid through so-called evaporation or misting through the vent tube. This is very common on certain models of NP 231 transfer cases, particularly those that are used in vehicles without a front-axle disconnect. In these vehicles, the transfer-case chain is turning whenever the vehicle is in motion in two-wheel drive. The chain action causes the ATF to become a fine mist, which leaves the unit through the vent until oil levels are too low. The customer will never see a leak and also will never check his fluid level, as he would have to go under the vehicle with wrenches to do so.

We have substituted 5W-30 motor oil in these applications and the oil loss stops. Motor oil is safe to use in this application, because the transfer case does not have a pressurized lube system. If you put motor oil in a BorgWarner transfer case with a pressurized lube pump, it would fail in short order, because the pump is not designed to handle that type of viscosity.

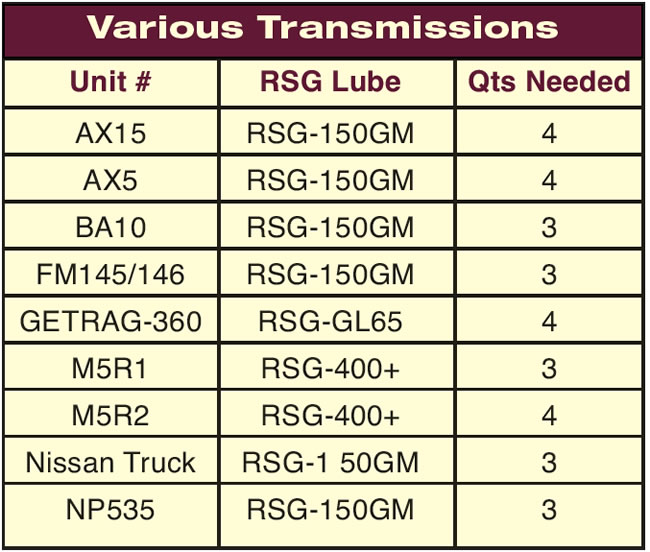

Similar problems occur with the M5R1 and M5R2 transmissions in the Ford light-duty-truck line. These popular Mazda-built transmissions are specified to run on ATF but can suffer from the same misting problem. If you put higher-viscosity motor oil or gear lube in these units, they will not shift correctly and the unit will make a moaning noise as the input oil slinger tries to move a much-heavier fluid. These units should be run on synthetic ATF, and you should make your customer aware of the need to have the transmission fluid checked more frequently.

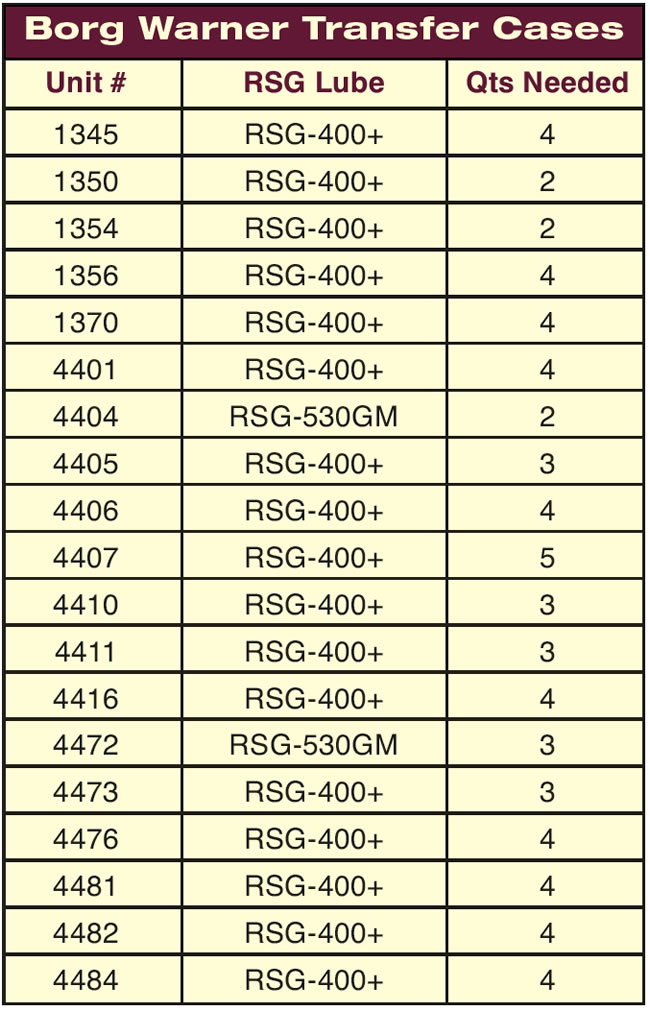

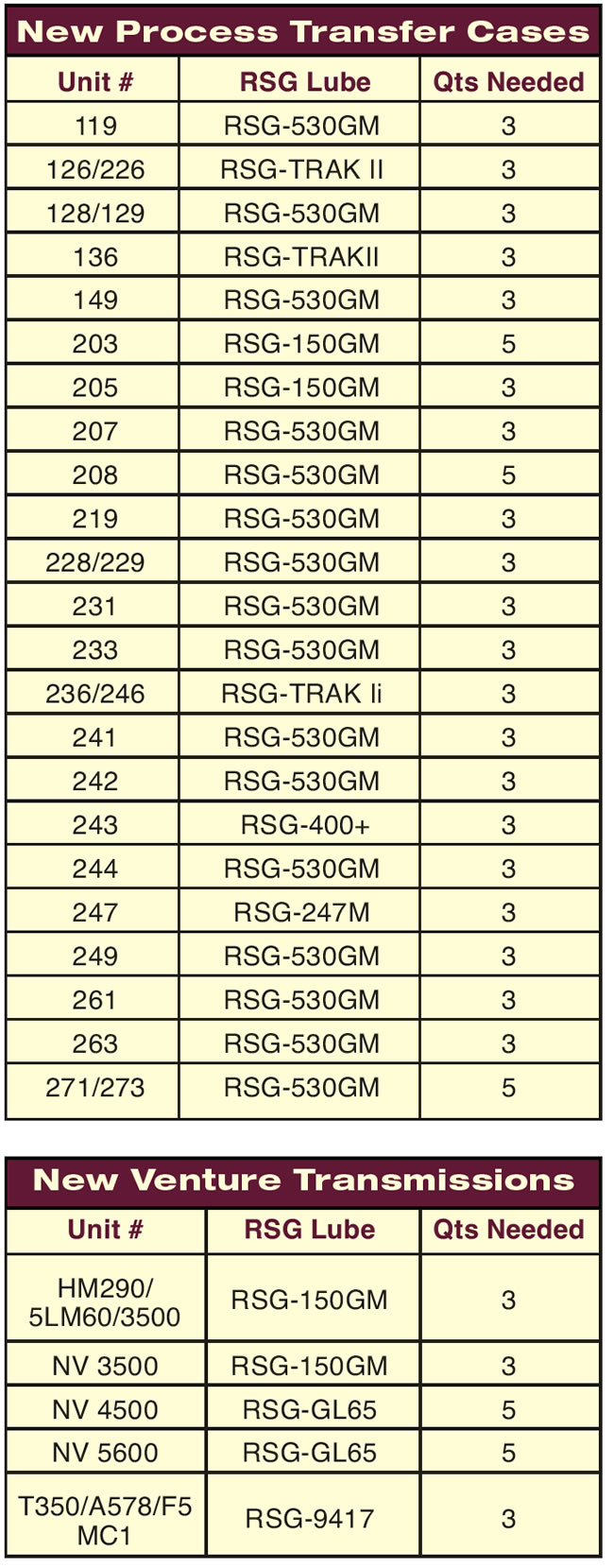

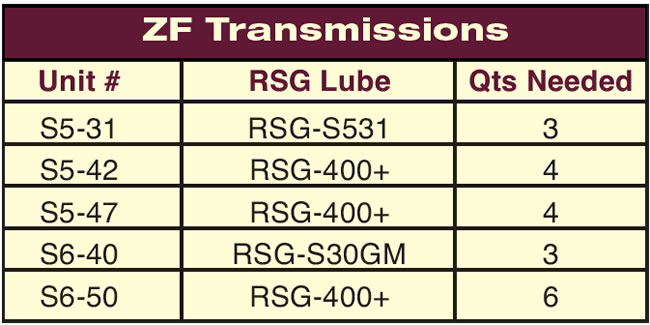

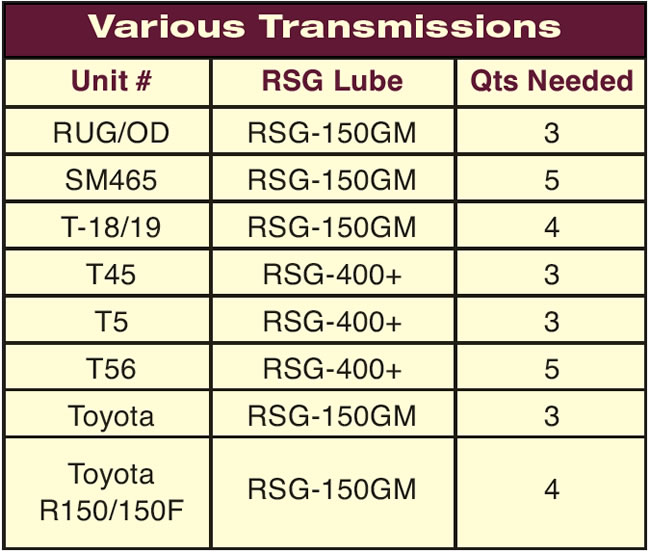

There are a great many new transfer-case models with computer-controlled clutch applications that require special fluids for proper clutch application and durability. Many of the GM units are specified to run on GM’s Auto Trak II fluid for proper operation. It is still possible to have clutch concerns and chatter even when the correct fluid is installed. This is common with the NP 136 transfer cases used in the S10, Bravada and Astro vans. The typical tech call goes like this: “I took the transfer case apart and didn’t find anything wrong with it. It chattered something terrible going around corners.” This will happen with high-mileage units where the fluid quality has failed with age. The fix here is to drain the fluid, replace it with new and add two bottles of Lubegard Red friction modifier. The chatter will continue for 100-200 miles of driving as the new fluid displaces the old in the clutch linings, but the results will be smooth operation again. Try the simple fixes first, and then take the unit apart if need be. To help you select the correct fluids, we have provided a lubrication guide for the most-popular units in the field.

Ignorance in our world is a really dangerous thing. Don’t assume, don’t guess; look up the specifications and use the correct oil. An incorrect oil will cause Neon transmissions to sing and not shift, NV 4500 units to weld themselves together (that makes a great boat anchor), ZF transmissions to be noisy and shift poorly, and any number of transfer-case malfunctions. You can’t go wrong with the factory fill unless research has been done to improve upon that.