Torque Converter Tech Tips

- Subject: Changes in torque converters

- Unit: Allison 1000

- Essential Reading: Rebuilder

- Author: Ed Lee

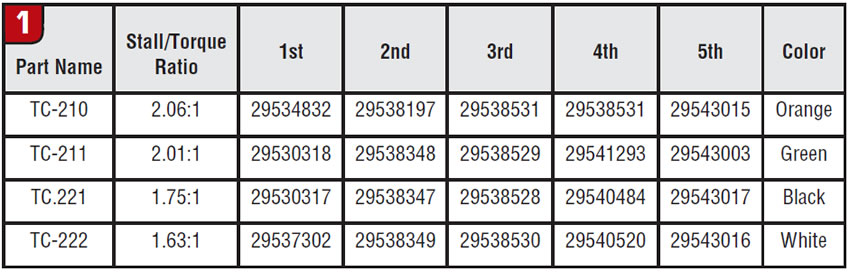

The Allison 1000 converter has evolved considerably throughout its existence. By the end of the 2007 model year there had been five different generations of this converter. The chart in Figure 1 lists the part name, stall torque ratio, part number and color ID code for the first five generations of this converter (Transmission Digest, November 2007, page 47).

The sixth-generation Allison 1000 converter was introduced at the beginning of the 2008 model year. There are still four basic configurations of this converter (TC-210, TC-211, TC-221 and TC-222). Each configuration has a different stall torque ratio and “K” factor.

The outward appearance of the sixth generation is the same as that of the fifth generation, and they also use the same four part numbers and ID colors on the barcode label. This is unique, because anytime a revision was made to the converter in the first five generations, a new part number was assigned.

The sixth generation has the same bolt pattern and overall height, as well as the same pilot and hub diameters, as the fifth generation. Despite all the external similarities, the impeller and piston/damper assembly are the only two parts that can be interchanged without any modifications. Many of the other parts are quite similar to the earlier version of this converter but would require some sort of shim, spacer or machining to be interchanged. The cover, for example, looks the same from the outside and even has the same barcode and part number; however, it has a different machined profile where the thrust washer rides (figures 2 and 3).

The thrust washer for the 2008 and newer converters does not have the locating step and is 0.050 inch thicker than that of the 2006 and 2007 fifth-generation models. The thicker thrust washer is necessary to maintain the proper endplay and overall height, because the thrust-washer cavity in the 2008 cover is 0.050 inch deeper than in the 2006-2007 models. Since the fifth- and sixth-generation covers have the same part number, you must take special care when interchanging parts. Remember, the two covers will interchange as long as the proper thrust washer is used (Figure 4).

The turbine is the same for both the fifth and sixth generations. There is a minor difference in the turbine hubs. The cross section of the turbine hub from the thrust-washer surface on the cover side to the bearing surface on the stator side is the same on both fifth and sixth generations. The 2006-2007 turbine hubs have a machined groove that is used to retain the enclosed bearing (Figure 5). The inner race of the enclosed bearing is designed to fit into the retaining groove of the turbine hub. This groove was eliminated in the 2008 model when the enclosed bearing was replaced with an open bearing.

If you are using a 2006-2007 fifth-generation bearing on a 2008 turbine hub, you may consider machining a groove into the hub to prevent stress on the inner race of the enclosed bearing.

The stator and corresponding bearings and shims are where you will find the biggest differences between the two generations. The impeller-side bearings both have the same 2.650-inch inside diameter, and both rest against a 0.030-inch-thick shim with three internal tangs. Both bearings are enclosed, and the only way to tell them apart is by measuring the thickness. The 2006-2007 bearing is 0.220 inch thick and the 2008 bearing is 0.250 inch thick.

The turbine-side bearings are easier to identify. The 2008 uses a 0.188-inch-thick open bearing, and the 2006-2007 uses a 0.220-inch-thick enclosed bearing. The turbine-side bearing shims are also different. The 2008 is 0.045 inch thick and the 2006-2007 is 0.030 inch thick.

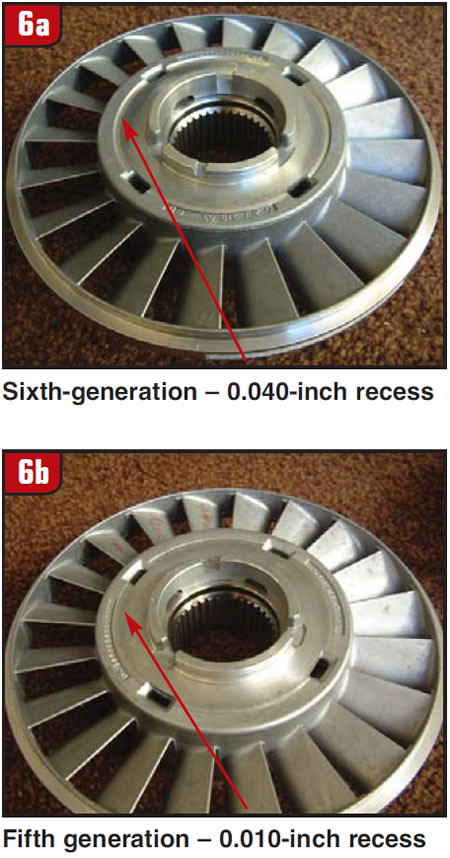

The stators are also different, to compensate for the difference in bearing thicknesses. The recess for the impeller-side bearing is 0.040 inch deep on the 2008 stators and only 0.010 inch deep on the 2006-2007 stators. The depth of the recess is the best method for identifying the stators (figures 6a and 6b).

Interchange rules for Allison 1000 fifth and sixth generations

- The impellers and piston/damper assemblies will interchange without modification.

- The covers will interchange if used with the correct thrust washer (endplay issues or possible thrust-washer breakage can result if mismatched).

- The 2006-2007 fifth-generation turbine assembly can be used with either the fifth- or sixth-generation stator assemblies. If a 2006-2007 stator assembly is used with a 2008 turbine hub, a retaining grove should be machined into the turbine hub to prevent the bearing race from cracking.

- The stators, with corresponding bearings and shims, may be interchanged if kept as a matched set. Mix-matching any one of these parts will cause a lot of grief.

Also remember that there are two different impellers and three different stators. They must be matched correctly to get the proper stall torque ratio and K factor.

Ed Lee is a Sonnax Technical Specialist who writes on issues of interest to torque-converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com. ©Sonnax 2009