Shift Pointers

- Subject: Operation of linear solenoids and shift valves

- Unit: Honda BAYA five-speed

- Essential Reading: Rebuilder, Diagnostician, R & R

- Authors: Jesse Zacarias & Roy Delfran

If you’ve ever tried reading the explanation given by Honda in its hydraulic charts on how the transmission shifts, then you know how it can be confusing and hard to visualize, to say the least. The intent of this article is to make it easier to understand, using capture snapshots of the actual shifts using pressure transducers. We hope this makes it easier to visualize, for as they say, “A picture is worth a thousand words.”

We will concentrate mainly on the shifting-solenoid valves (SSV); linear solenoids A and B, which control clutch-pressure-control (CPC) oil; and the shift valves.

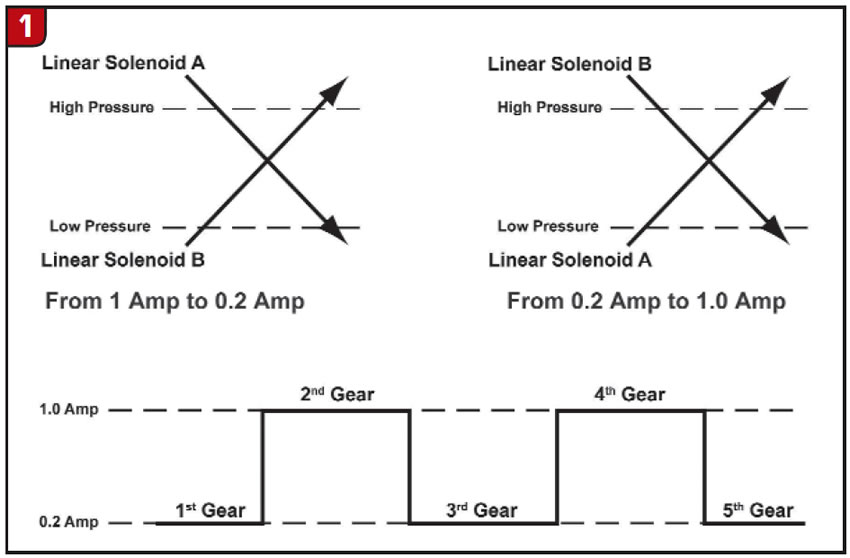

Linear solenoids A and B are responsible for controlling the clutch-pressure-control (CPC) oil. The PCM modulates linear solenoids A and B to control the gradual engagement and disengagement of the clutches that are coming on and going off. It does this by slowly increasing or decreasing the amperage. Linear solenoid A increases pressure with the increase of amperage, and linear solenoid B does the opposite; that is, it decreases pressure with increase of amperage. You can see them in action when you look at the X made by the releasing pressure and applying pressure of a clutch between shifts in the snapshots provided in this article.

See Figure 1 for the following explanation. In first gear both linear solenoids start at low amperage and are gradually modulated to high amperage as the transmission shifts to second gear. In second gear, both linear solenoids start high and are modulated to a low-amp level as the unit shifts to third gear. In third gear, both linear solenoids start low and are modulated to a high-amp level as the transmission shifts to fourth. In fourth gear, both linear solenoids start high and are modulated to a low-amp level as the unit shifts to fifth gear.

With the exception of the 1-2 shift, every shift is initiated and completed by a shift solenoid turning either on or off. That is why we have nine different solenoid stages for this five-speed transmission – one stage for when it is in a particular gear and another stage for between gears.

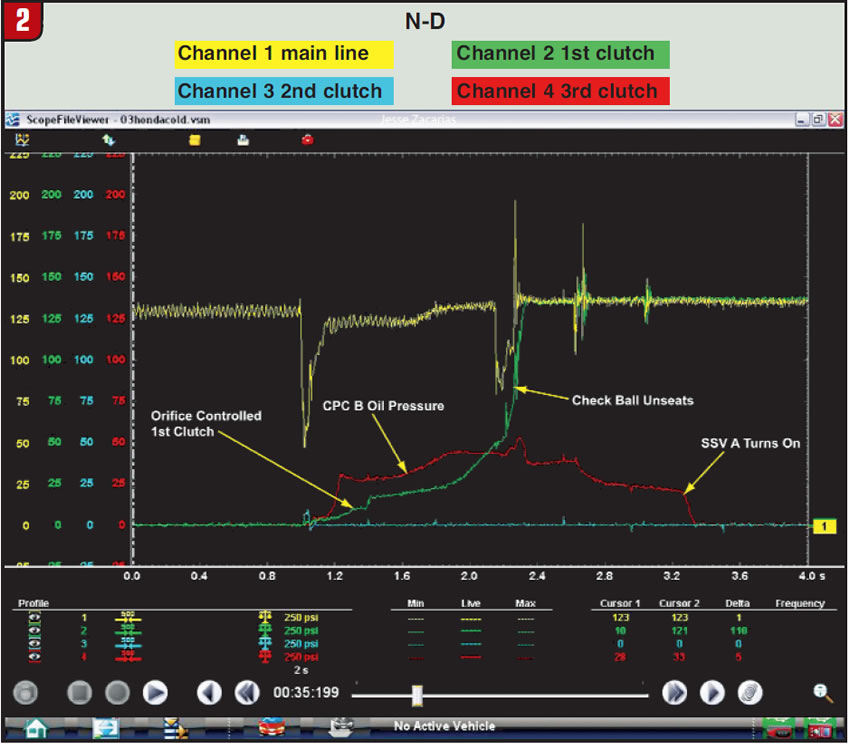

Let’s start by looking into the Neutral-to-Drive engagement.

See Figure 2 for the Neutral-to-Drive explanation. In Neutral, SSV C and SSV A are off while SSV B is on. When the transmission is placed in Drive, main line pressure starts to enter the first clutch through an orifice (channel 2) at the same time linear solenoid B, which is at 1 amp, starts to decrease amperage, which causes CPC B pressure to increase and to enter the third-clutch circuit (channel 4). Linear solenoid A is turned to minimum pressure at 0.2 amp. Linear solenoid C is modulated to produce CPC C pressure that is routed to fill the first-accumulator back side.

When orifice control pressure unseats the checkball, then main line pressure enters undisturbed to the first clutch. By this time CPC B pressure has increased enough to engage the third clutches for a smooth engagement (around 35 psi). Shortly after the first clutch is fully engaged, the PCM turns on SSV A first, to exhaust CPC B pressure from the third-clutch circuit at H3X exhaust, and then later SSV C is turned on in preparation for future shifts. All this takes place in about two seconds. The transmission is in first gear and SSV A, SSV B and SSV C are on.

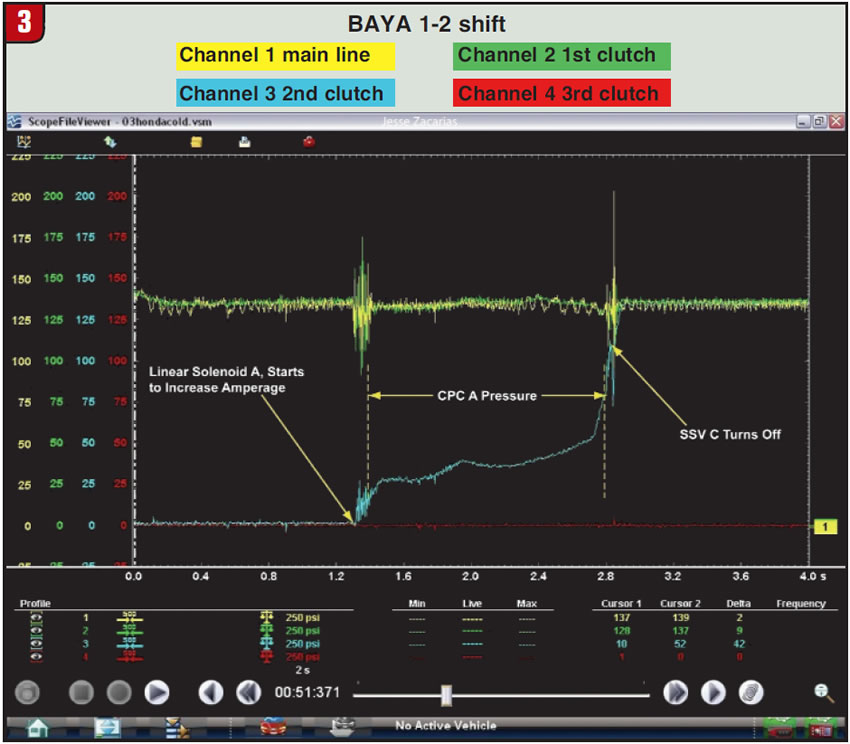

See Figure 3 for the explanation of the 1-2 shift. In first gear, SSV A, SSV B and SSV C are on and linear solenoids A and B are at 0.2 amp. As the road speed increases before the shift to second, the PCM starts to increase amperage to linear solenoids A and B. As the amperage increases, CPC A pressure increases and CPC B decreases. You can see the increase of CPC A pressure entering the second clutch in channel 3 (blue tracer). At a predetermined pressure increase the PCM sees the change in output-shaft speed and turns off SSV C, causing shift valve C to stroke, thus connecting second-clutch pressure directly to main line pressure that is present at shift valve C. Since the first clutch is now being released there is no need to time the apply clutches. The sprag starts to freewheel so no power is transmitted through the first clutch. All this takes place in about 1.6 seconds, and the transmission is now in second gear.

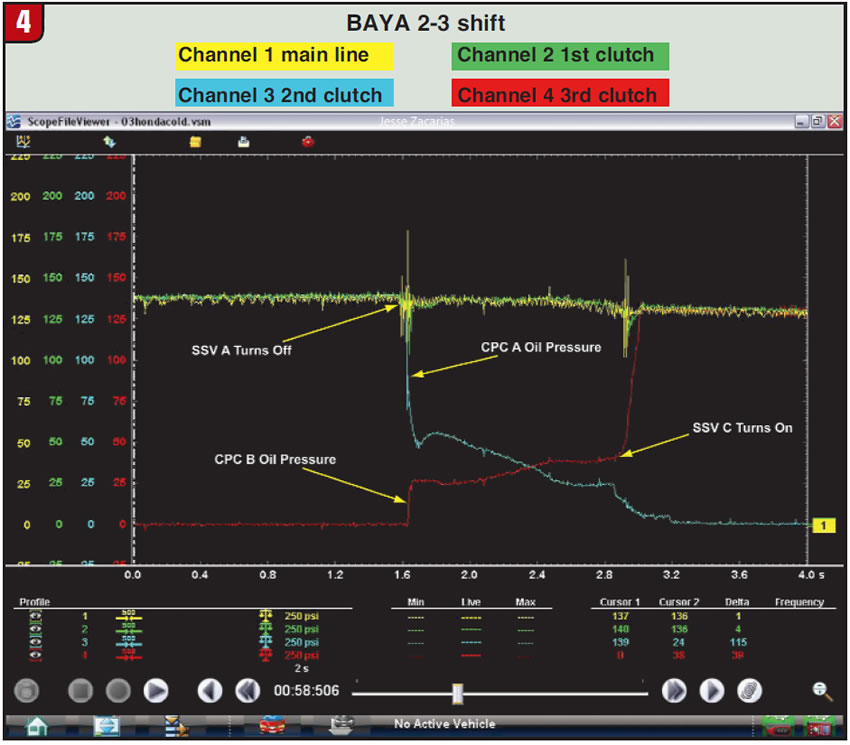

See Figure 4 for the 2-3 shift. In second gear, SSV A and SSV B are on while SSV C is off; linear solenoids A and B are at 1.0 amp. To initiate the 2-3 shift, SSV A is turned off, stroking shift valve A. This connects second-clutch pressure to CPC A pressure, which is being dropped gradually; thus, CPC A pressure becomes the releasing pressure (channel 3, blue tracer). At the same time shift valve A also connects CPC B oil pressure that is being increased gradually to the third clutch; this is the on-going clutch (channel 4, red tracer).

When the PCM sees the third pressure switch turning off, and CPC B pressure has reached a predetermined pressure, it finishes the 2-3 shift by commanding SSV C on, causing shift valve C to stroke. This connects second off-going pressure to exhaust H2X and on-going third clutch to main line pressure. The 2-3 shift is finished and the transmission is in third gear, all in about 1.4 seconds.

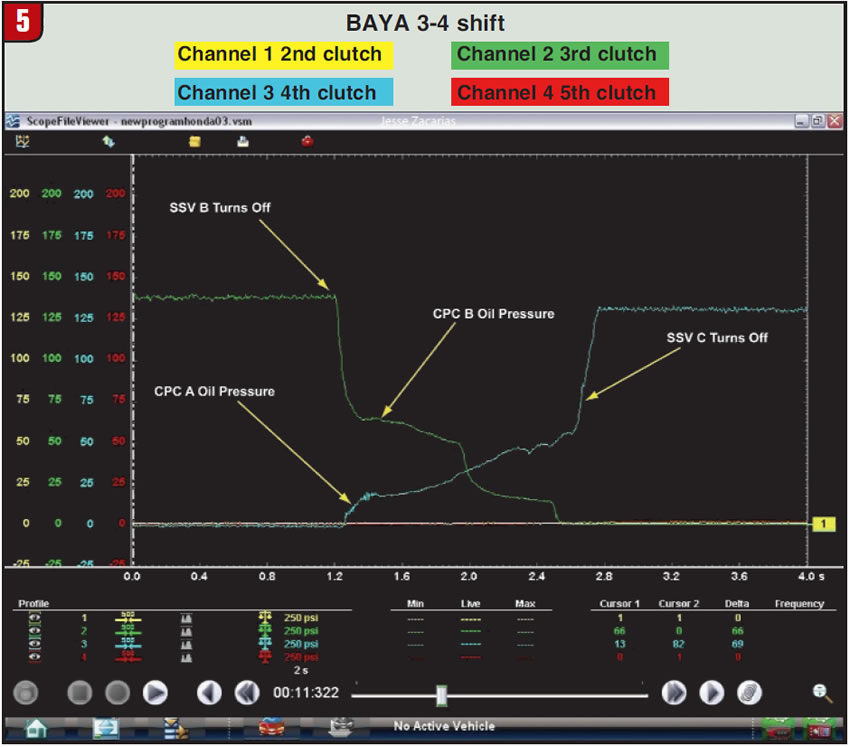

For explanation of the 3-4 shift see Figure 5. In third gear, SSV B and SSV C are on while SSV A is off; linear solenoids A and B are at 0.2 amp. To initiate the 3-4 shift, PCM turns SSV B off, stroking shift valve B. This connects the third clutch to CPC B oil pressure that is being gradually lowered, and the third clutch thus becomes the off-going clutch. This also connects the fourth clutch to CPC A pressure that is being gradually increased, and it becomes the on-going clutch.

When CPC A pressure has reached a predetermined level the PCM turns off SSV C, stroking shift valve C and connecting off-going third CPC B pressure to exhaust H1X and connecting the on-going fourth clutch to main line pressure. The vehicle is in fourth gear and SSV A, SSV B and SSV C are all off. This is accomplished in about 1.6 seconds.

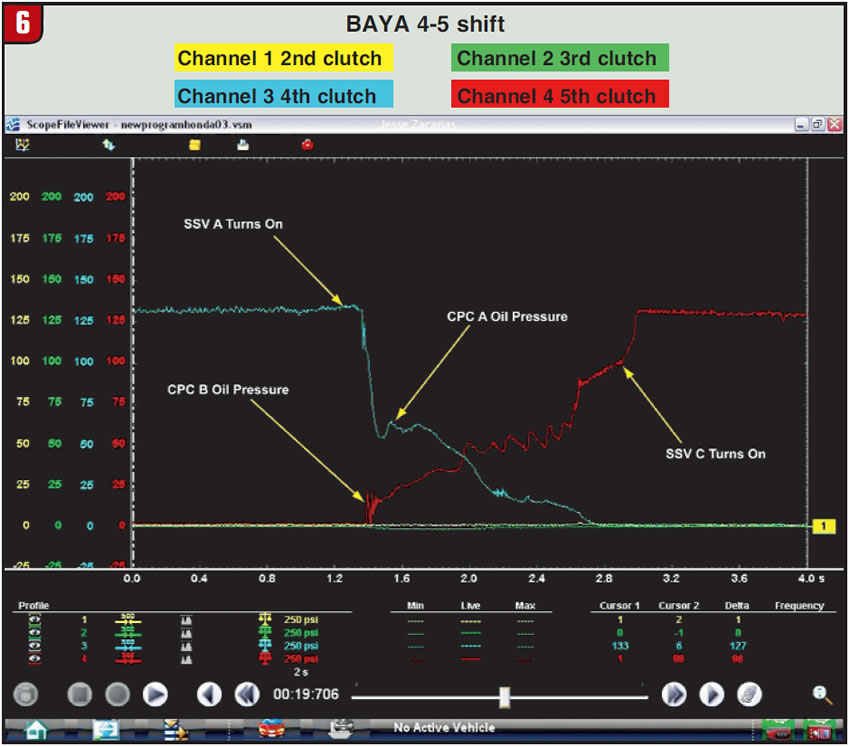

For explanation of the 4-5 shift see Figure 6. In fourth gear SSV A, SSV B and SSV C are off. To initiate the 4-5 shift, the PCM turns on SSV A, stroking shift valve A. This action connects the fourth clutch to CPC A pressure that is being lowered gradually, and the fourth clutch becomes the off-going clutch. At the same time CPC B pressure is connected to the fifth clutch, the on-going clutch.

When CPC B pressure reaches a predetermined level, the PCM turns on SSV C, stroking shift valve C. This action connects the off-going CPC A pressure to exhaust H2X and on-going CPC B pressure to main line pressure, and the shift is done in about two seconds. The vehicle is in fifth gear and SSV A and SSV C are on, while SSV B remains off.

When a Honda five-speed has shifting concerns, we have seen parts replaced unnecessarily because of the lack of understanding. Linear solenoids are prone to sticking, and the pressure switches can become unreliable to the point of causing flares or bind-ups during an upshift or downshift. Linear solenoid C can cause problems with torque-converter-clutch engagement or harsh neutral-to-drive engagements. We hope this information helps you to better understand the shifting characteristics of the Honda five-speeds and the role that the SSV solenoids and linear solenoids play.

Special thanks to Bill Turney from Snap-on for his help with the graphics.

Jesse Zacarias is the owner of Elec-Tran Diagnostics (www.electrandiagnostics.com) in Gilroy, Calif. Roy Delfran is with Snap-on Diagnostics “Ask-a-Tech Web Services” (http://askatech.snapon.com).