Technically Speaking

- Subject: Valve-body components and operation

- Unit: VW DSG 02E

- Vehicle Applications: 2004-up New Beetle, New Jetta, Golf GTI

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

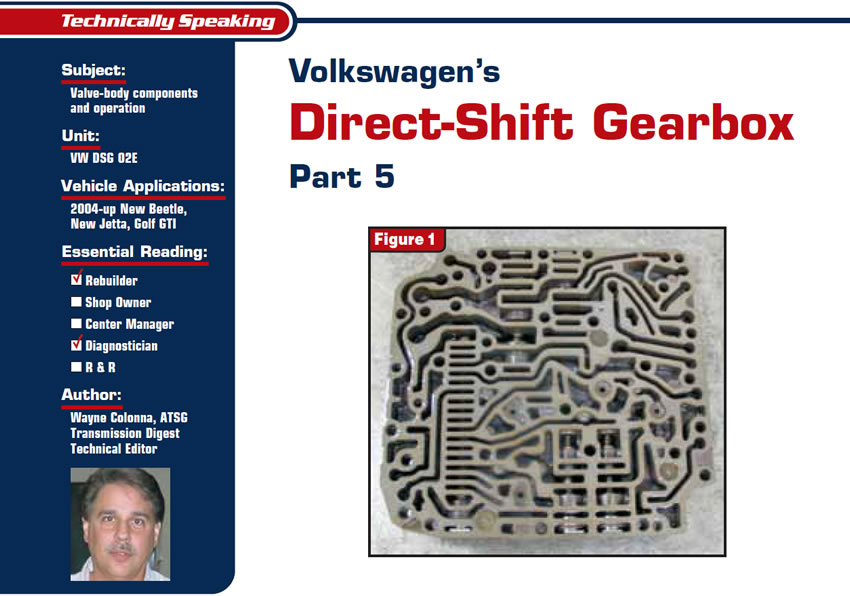

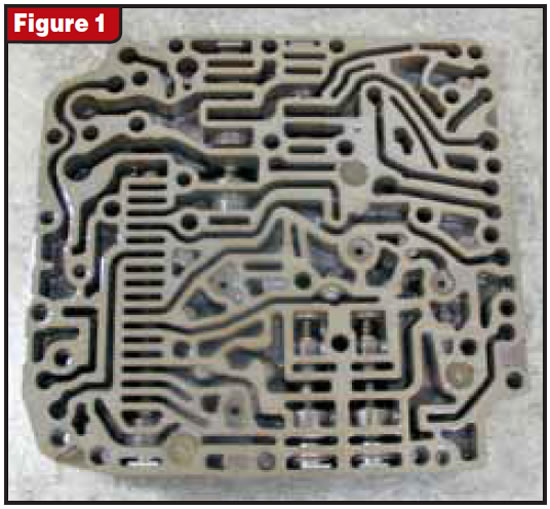

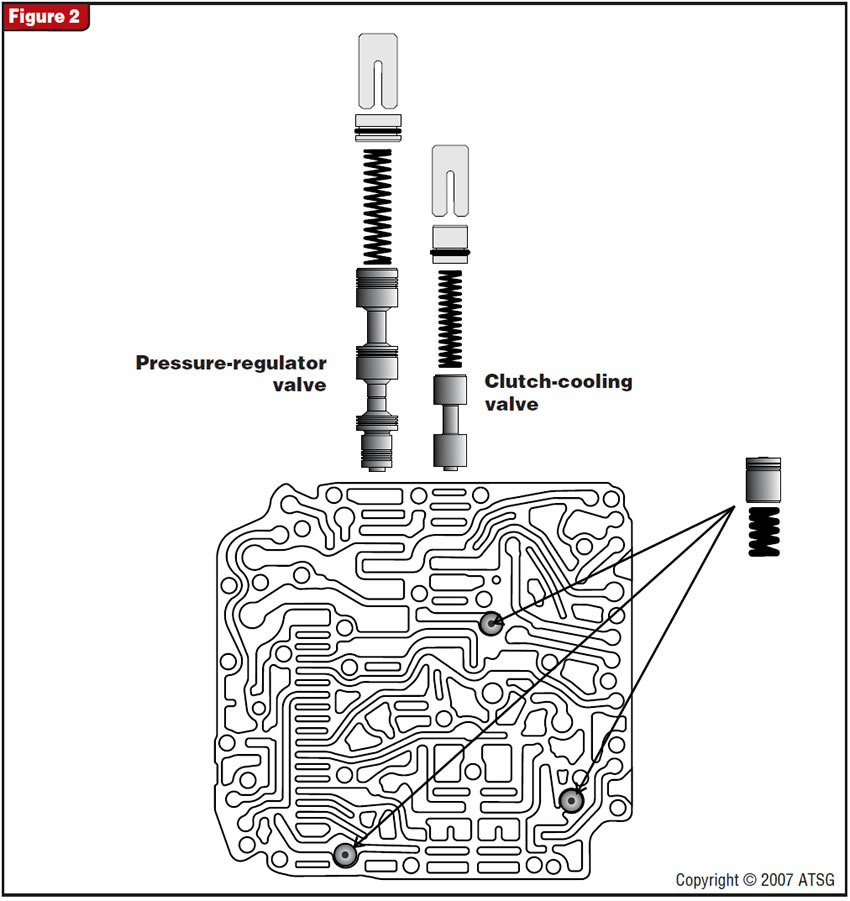

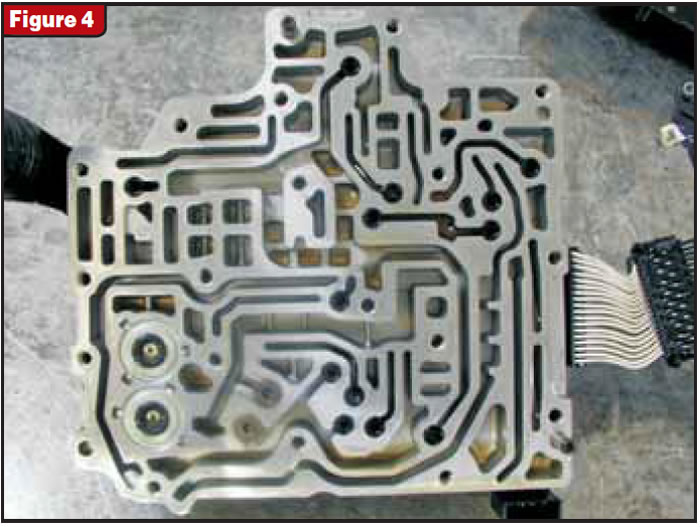

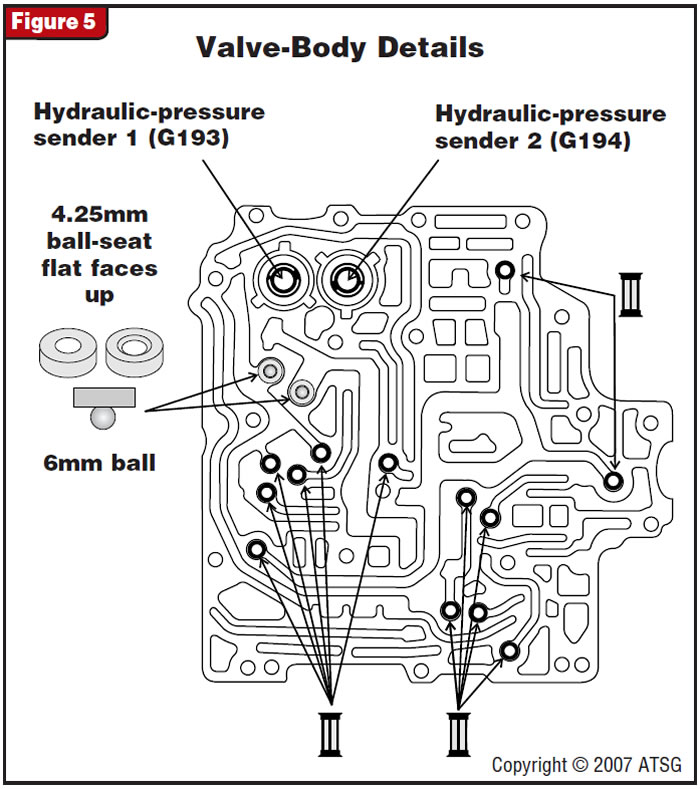

The DSG valve body is definitely one of the simplest we have seen in transmissions (see figures 1 through 5). It contains only five valve line-ups, two checkballs, three damper assemblies, two pressure senders (pressure sensors/transducers) and 13 filters (see figures 2, 3 and 5).

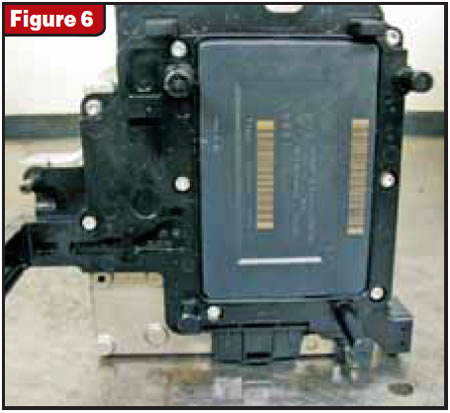

The two checkballs and pressure senders are in the K1- and K2-clutch pressure circuits, which are being used for precise clutch-pressure control and release. These sensors are integral to the TCM and are staked into the channel-plate portion of the valve body (see Figure 4), making these sensors non-serviceable separately. This also means that the TCM cannot be easily removed from the valve body even if you remove all the bolts (see Figure 6). So it appears that if a pressure sender fails, you will be buying a TCM/valve-body assembly to correct the problem.

It is no secret that the manufacturers are doing everything they can to get us to the place where all we can do is unit replacements – very un-American, in my opinion. If you prevent the middle-class working man from earning a living, you weaken a country. It is not typical of me to get on a soapbox like this, but the things we are seeing in the automotive business have me very concerned.

Try to buy transmission parts for a Nissan Murano; it cannot be done. You are forced to buy a whole transmission. Our politicians do not give a hoot about America, just their back pocket. It sure would be nice if our automotive associations had more clout on The Hill. OK, I am done; back to tech. Thank you for giving me a few minutes to blow off some steam.

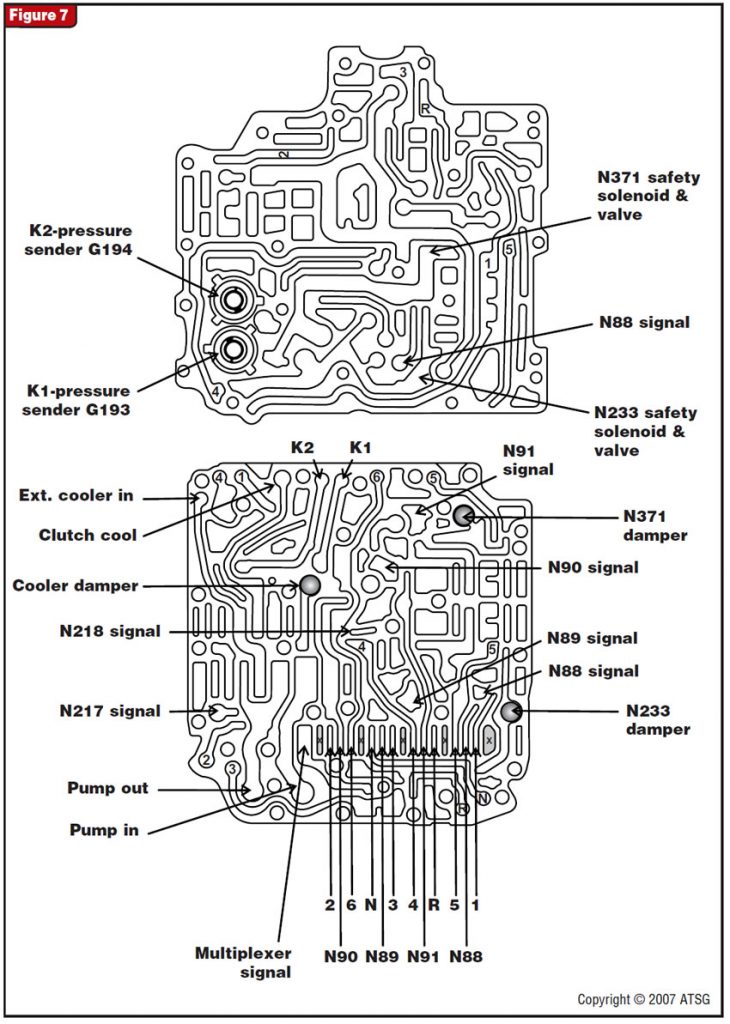

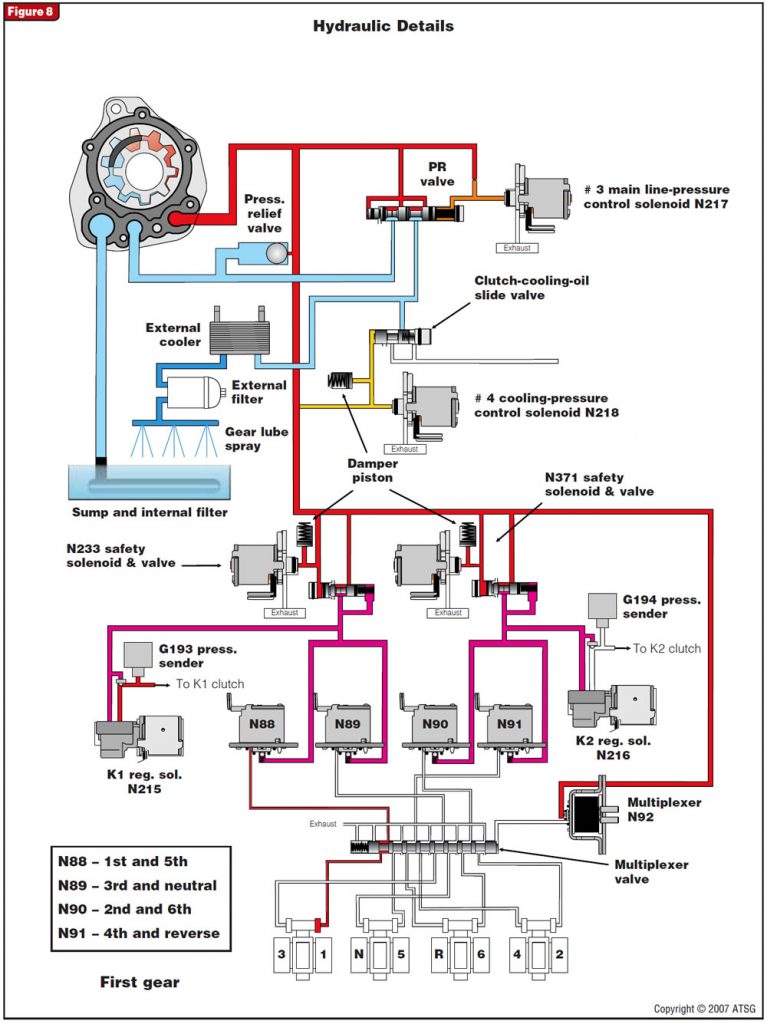

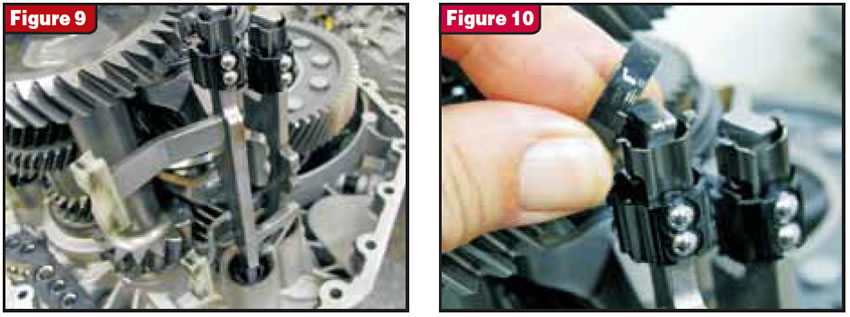

With the valve body as simple as it is, it does not take much effort to identify and trace hydraulic circuits, as I did in Figure 7. This becomes helpful in identifying case passages for testing. For example, if you look below the multiplexer valve in the hydraulic circuit shown in Figure 8, the shift rails inside the transmission are represented. From left to right you have the 3-1 shift rail, the N-5, the R-6 and then the 4-6. Each end of these shift rails sits inside a cylinder containing a piston seal known as a gear actuator (see figures 9 and 10). When you look at Figure 11, you can see how one can inspect these gear actuators for leaks with compressed air through their respective case passages.

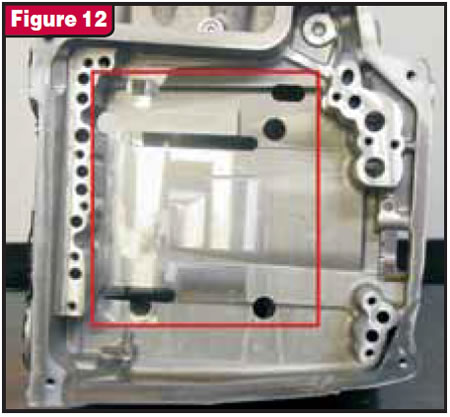

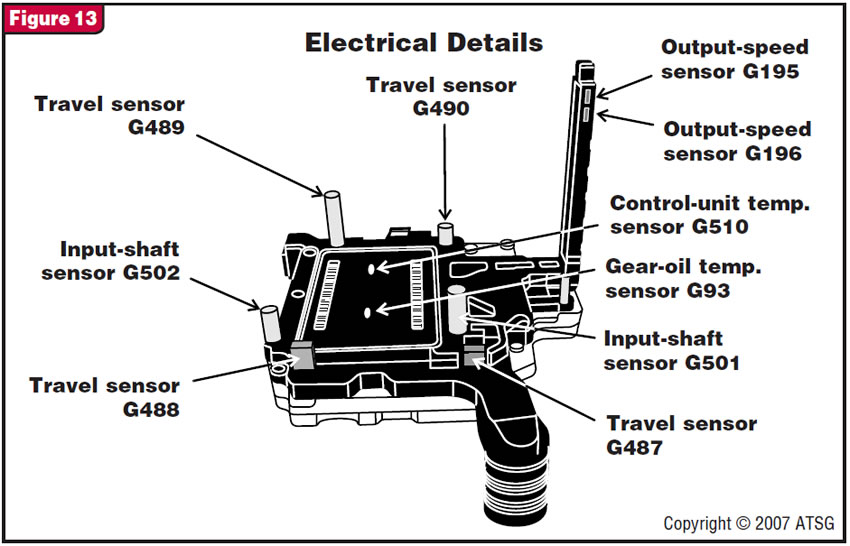

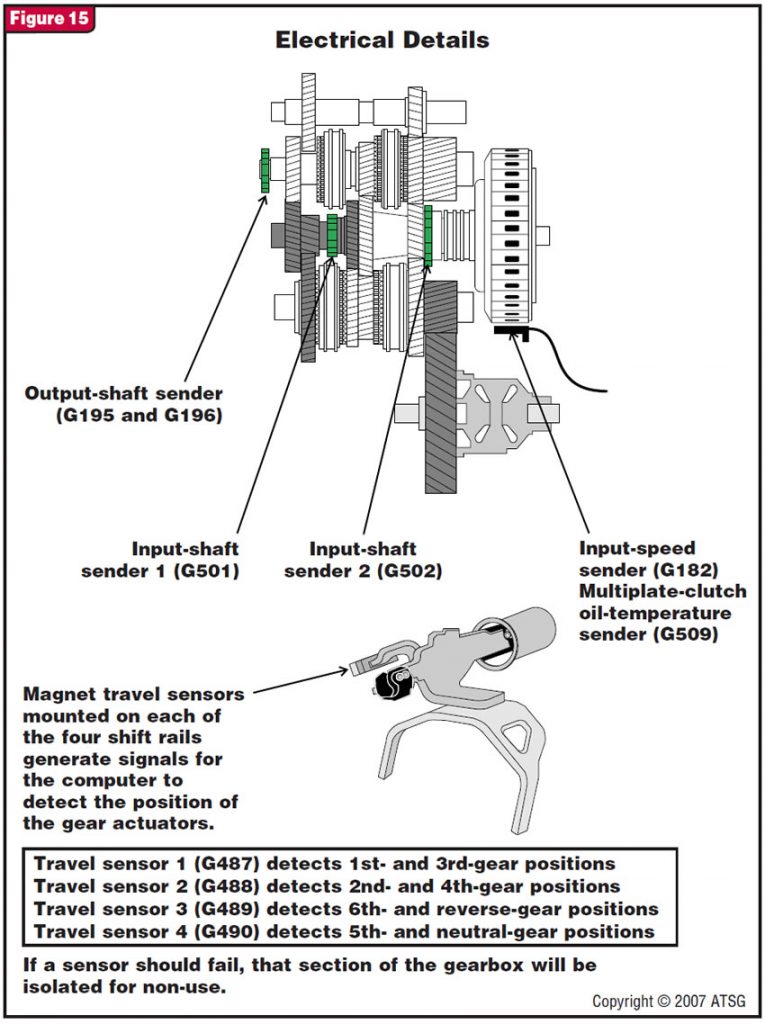

You also will notice that there are slots and holes within the center of the case as shown in Figure 12. These are openings for various sensors built into the TCM, which are identified in Figure 13. Four of those sensors are called “travel sensors.” They monitor the position of the four shift rails by reading the magnet travel senders that are affixed to each of the rails (see figures 14 and 15).

The other sensors and senders identified in figures 13 and 15 are:

• The input-speed sender (G182) is a Hall-effect sensor that reads the outside of the K1/K2-clutch drum, which rotates at engine speed. This signal is used to calculate clutch slip for a more-precise control of clutch apply and release. In the event of a failure, the redundancy backup is an engine-speed signal, which the transmission computer receives over the CAN (controller area network) bus.

• The multiplate-clutch oil-temperature sender (G509) is also inside the same housing as the input-speed sender, and it measures the temperature of the oil as it comes from the outlet ports in the drum assembly. From this input, the transmission computer regulates the flow of clutch-cooling oil and initiates further measures to protect the gearbox. It measures temperatures rapidly and works within a range from –55° C to +180° C. As a backup should this sensor fail, the transmission computer uses signals from the gear-oil temperature sensor G93 and the control-unit temperature sensor G510, both inside the transmission computer.

• Input-shaft speed sensor 1 (G501) and input-shaft speed sensor 2 (G502) are both Hall-effect sensors inside the transmission computer. These sensors are excited by the wheel-speed sensors mounted on each shaft. These signals are used in conjunction with the input-speed signal (G182) to determine the output slip of clutches K1 and K2. Besides using these signals to tailor clutch-slip control, it also can determine whether the right gear ratio has been selected. If sender G501 fails, only second gear can be achieved. If sensor G502 fails, only 1st and 3rd can be achieved.

Output-speed sensor G195 and G196 are also Hall-effect sensors inside the transmission computer. They, too, are excited by a wheel-sensor mounted on the shaft. By having two output-speed signals that are offset, the computer can detect direction of travel. The G195 sends a “high” signal and the G196 sends a “low” signal. As a redundancy should these sensors fail, ABS wheel-speed signals are substituted for both direction of travel and road speed.

• Gear-oil temperature sender G93 and control-unit temperature sender G510 are both inside the Mechatronic transmission-control unit. With this unit being placed inside the transmission, the oil temperature can be monitored. These two sensor signals are used to check the Mechatronic’s temperature, they are used to start a warm-up program and they check each other for faults. If an over temp is detected, measures are initiated to reduce oil temperature as rapidly as possible to avoid excessive heat generation in the Mechatronic unit. At temperatures that exceed 138° C, the Mechatronic unit initiates a reduction in engine torque. Above 145° C, oil no longer is supplied to the K1 and K2 clutches, placing the transmission in neutral.

This concludes the series on the DSG 02E gearbox designed to give you an idea of the type of transmissions we can expect to see more of. Its compact design and the elimination of a torque converter are quite favorable for the manufacturer.

So now we have CVTs, DSGs, six-speed front- and rear-wheel-drive transmissions, AWD transmissions and, yes, there is now an eight-speed rear-wheel-drive transmission by ZF. It looks as if we could do well in the transmission business if we could buy parts. Is the right to rebuild being taken from us one transmission at a time?