With a history and reputation dating back to the 1980s, growth is a continuous pattern at Milwaukee’s ETE Reman. CEO Noah Rickun says that ETE is ready to meet the ever-expanding demand for remanufactured transmissions. He points to a combination of available capital to invest in the facilities, equipment, technical capabilities, and the well-trained workforce needed to continue the ETE tradition of supplying quality units to the aftermarket.

“Since its inception, ETE Reman has never experienced a year without double-digit growth—an impressive feat for any business in this up-and-down world of the automotive aftermarket,” Rickun says.

The company was founded by Sam Loshak, Rickun’s father-in-law, in 1985 as Engine and Transmission Exchange, and it rebuilt and installed both engines and transmissions.

“However, as the business was growing, back around 2005 or 2006, we came to a point where we had to make a choice,” Rickun says. “If we really wanted to grow the transmission business, we needed to take as many of our people and as much of our money as possible out of engines and bet on the transmission business. I remember Sam telling me, when we convinced him to shut down the engine factory, that it was like cutting off one of his arms. It was a big part of our life. We were just too small to be able to be expert in both.”

It was a bet that paid off. “Demand for remanufactured transmissions has never been higher,” Rickun says. People are keeping their vehicles longer than ever and the number of transmission rebuilders has been declining steadily as the units become more and more complex and computerized, and as transmissions move into eight-, nine- and ten-speeds. And the decline in builders accelerated even more during the Covid-19 pandemic.

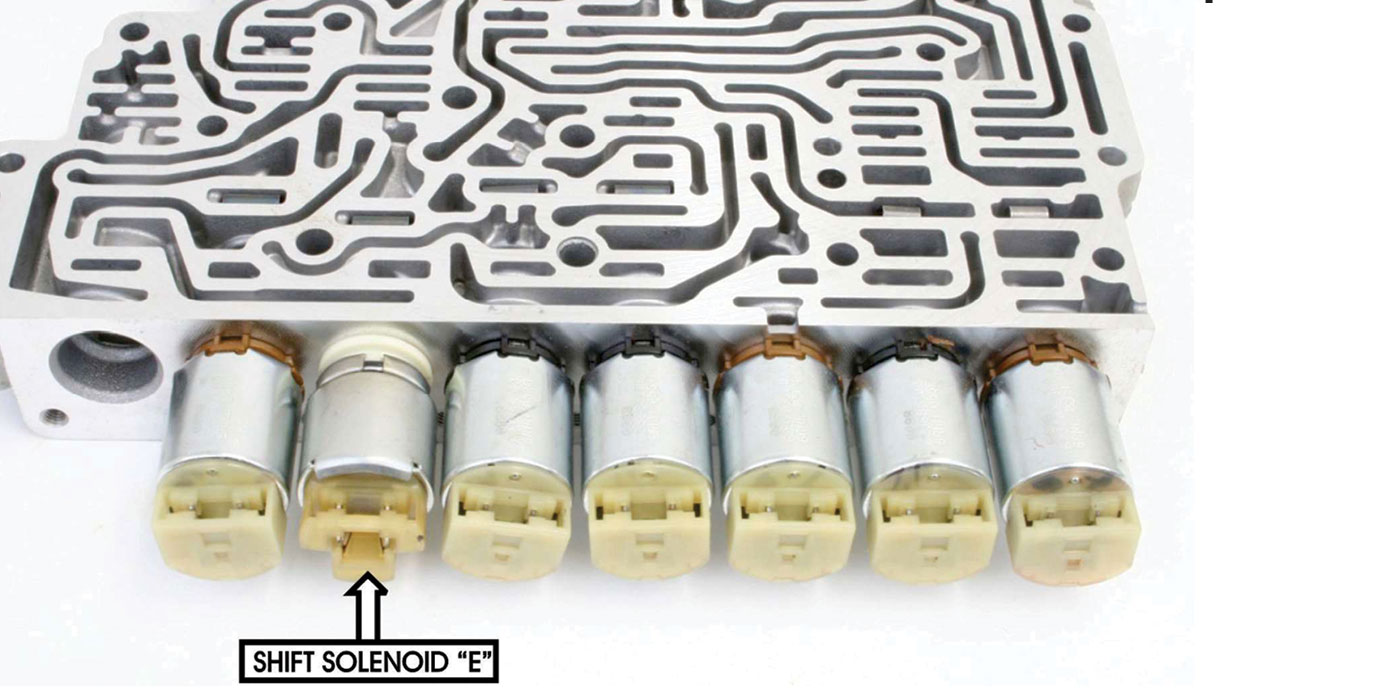

“As a remanufacturer we’ve had to change our hiring process over the last 10 years,” Rickun explains. “We can’t hire builders because they just don’t exist in the numbers we need. We now have 761 employees and are growing every day. I don’t know where we could find 761 transmission builders in this country who are willing to work in Milwaukee. So, we’ve changed our process and broken it up in a way that we can train a person with some mechanical aptitude on how to perform a discrete operation, like a valve body rebuild, a TEHCM reprogramming or a sub-assembly, like a drum or a pump in 30 to 60 days. And that allows us to really broaden our search when we’re looking for new employees.”

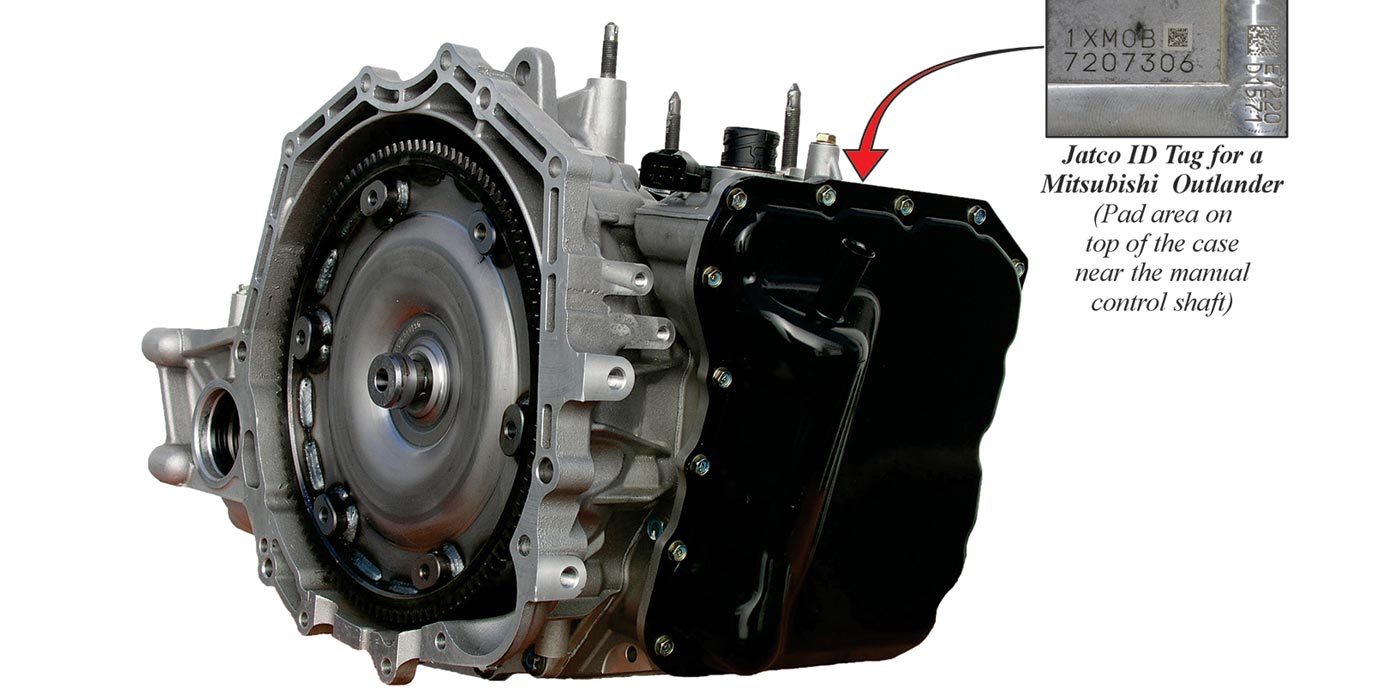

In 2019, ETE acquired the Automatic Transmission Service Group (ATSG) to oversee the technical aspects of reman operations.

“We partnered with ATSG because they know what’s happening in the transmission market before the average remanufacturer knows,” Rickun says. “They’re answering calls every day from shops all around the country.

“Because ATSG knows what’s failing in OEM transmissions in the field, ETE can task its R&D department to find proactive solutions and stay a step ahead of the industry,” he continues. “ATSG literally wrote the book on transmission tech solutions, so ETE uses them as a resource in our remanufacturing process and in quality control. As eight-, nine- and ten-speeds begin entering the aftermarket, we’ll continue to have a leg up because of ATSG.

“With demand ever growing, ETE is always hiring. We’ve won top workplace awards for the past three years and have a wonderful reputation in the Milwaukee market,” Rickun says.

Rickun says that one of the things he’s most excited about is an in-house training program called ATSG academy, which was started last year. “During a new employee’s first week,” he explains, “they’ll spend four days at the academy learning the history of transmissions, the history of ETE, our company’s core values, their role in the company, and how they fit in to the organization.

“Together, during their last class, students build a six-speed transmission from the ground up. It’s a great introduction to our business and a neat thing for them to be able to do. ATSG Academy has helped us continue to increase our quality and has helped reduce production-employee turnover by more than 50 percent.”

Earlier this year, ETE entered into an agreement with Dallas-based equity partner Gauge Capital. “It’s a very founder-friendly firm,” Rickun says. “Gauge is a mid-market company made up of investors, not operators, which allowed our family to retain a significant amount of ownership and control in running the business day-to-day. Everybody wants to know what will change. Nothing for the worse, but we now can grow faster and smarter.

“We had come to the point where it was time to capitalize on growth opportunities in a way that we couldn’t do by ourselves anymore,” he adds. “Taking on a private equity partner was a way for us to continue running the business in the way that we always have, to stay committed to our core values, which are rooted in family values, and take advantage of a nice capital infusion allowing us to grow faster than we would otherwise.”

Rickun added that a newly acquired, 50,000 square-foot warehouse will hold core inventory, allowing additional remanufacturing capacity at ETE’s main production facility. ETE, he says, is committed to helping energize and uplift the local community. The main production facility is a revamped Super Walmart, their original 60,000 square foot production facility is now strictly for the remanufacture of torque converters. Shipping is expedited from what once was Toys R Us retail space, and ETE’s corporate headquarters occupies a former bank office. All five buildings are within a two-mile radius.

As market demand grows, along with their production capacity, we asked which transmission families ETE is focused on. At that, Rickun laughed. “I don’t know who said it, but I’ve always liked the saying that you fish where the fish are,” he says. “We are always looking at where the demand is in the industry. Today, that’s domestic rear wheel drive platform vehicles. That may be changing a little bit with Ford having gone to a front-wheel-drive platform, but it’s still SUVs and trucks. That is the primary market for almost everybody in the transmission business. There are units that we don’t remanufacture, as we’re more concerned about the quality.

“We’re purposely slow to release transmissions to the marketplace. We want to be sure they’re dialed in perfectly before we do,” he says. “Quality is job one, two and three in our business. In 1985, we began by actually working on customers’ vehicles, and we still do. In fact, some of the same employees that Sam opened with are still with us.”

ETE has two retail shops, one with 21 lifts and the other with 12.

“Not only are they profitable businesses,” Rickun says, “but they’re also great R&D centers for us. Besides dyno testing every transmission that goes out the door, we also get to test many improvements in our own shops before we send them out to other shops. So, it’s a great learning opportunity for us, and it’s how we’re able to confidently say that our transmissions are, ‘like new, only better.’”