Most certainly one of the pioneers of the transmission aftermarket, Precision International founder and CEO Dennis Marshall recalls the formative days of his company, and for that matter, the industry we know today. Precision International is soon to celebrate a legacy of 50 years serving the powertrain aftermarket. The company opened for business as Manufacturing Gaskets Worldwide (MGW) and was located in Deer Park in a 10,000-square-foot facility on Long Island.

Marshall’s story is made more compelling in an industry that’s experienced a 25-year consolidation by way of a succession of mergers and acquisitions. Precision International remains a family business boasting both a very long-serving leadership team and a family succession plan. Marshall’s family members working at the company include his daughter, purchasing manager Tina Parente; and two granddaughters: Toni, who also works in purchasing, and Kacy, who has duties in the accounting department.

From the conference room of the company’s 90,000 square foot facility in Yaphank, Long Island, Marshall talks about leaving his job at Allomatic, where he began working in 1959 as a warehouse worker working himself up to sales manager and trusted confidant. He left to start his own business in 1975.

“I gave Beno (Bordiga, founder of Allomatic) a year’s notice. I’m probably the only one to have left there with everybody feeling nicely. And I worked with Beno even after the year was finished, I handled some of the sales meetings and customer interactions when he moved to Queens. We stayed very friendly until he passed away,” Marshall recalls. “Part of our agreement was that I would not compete on similar products, hence the foray into paper and rubber and overhaul kits.

“Those were difficult years when we first started; getting parts was the issue,” he continued. “We had no trouble getting customers because I’d been in the business a long time before I started this company and I had many contacts and friends. But then, a lot of suppliers would not sell to us. So that, certainly, was our most difficult challenge.

“It was Western Acadia at the time [later ACA] that promised me they were going to sell to me. One of the people there made sure we didn’t get what we wanted to purchase. But we got a GM contract within six months, and he was really upset. I had a lot of contacts at GM from my days at Allomatic. So I got an order to package GM kits, and that forced Acadia to sell to us.”

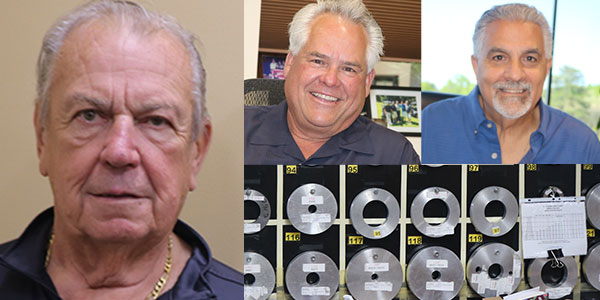

Marshall points to a framed photo on the conference room wall (seen in the image at the top of the page) and says, “that kit is for the C4. That’s the first one we ever made and it was an easy kit to make. Our earliest kits were that one, the TorqueFlite 6 and TorqueFlite 8, small basic paper and rubber sets.

“As we grew bigger and bigger, the name change was just by accident. We branded our foreign kits ‘International.’ That what was printed on the bag and all. I don’t remember whether it was Frank Miller, John Sollazzo or somebody else at the company who asked, ‘well, why don’t we just make it Precision International?’ And that’s how the name change came to be.

“Initially the kits were being packed up and shipped out right away,” he continues. “We kept some minimal inventory. But, you know at that time there were something like seven basic domestic transmissions and a small handful of foreign. There were a couple of Toyotas, a Honda, a Nissan. So we concentrated on units like C4, C6, TH350, TH400, TorqueFlite 6 and TorqueFlite 8. We ran those ‘til the cows came home; every day we’d run 5,000 or 6,000 of those.”

“When [Dennis] got into this business,” shares John Sollazzo, the company’s vice president of sales and marketing, “he had established customers like Ajax Transmissions and Altran, who at the time were very large national distributors. They were local to us. We were their warehouse, in effect. We would run the kits and then put them in a truck and deliver to them as needed. They weren’t putting it on their shelf they shipped the kits right away all over the country. They ordered them and we’d package them and deliver them to them, and they were filling orders. This was an everyday process.

“The kit business is not easy,” Sollazzo observes. “If it was, any number of companies would have done it long ago and there are dozens who were once in the kit packaging business who are now long gone. This makes Dennis’ journey even more impressive.”

Marshall says that the challenges have evolved over time but that the business has always been one of knowing what the builder needs, finding reliable sources of components, acquiring the parts, packaging them accurately and moving the finished kits to market.

Today’s most notable challenges revolve around specifying and then finding sources for the thousands of parts that go into the kits. “When we talk about rings, I don’t know how much I can lighten the car going to a plastic from a metal ring. But for these plastic rings the tooling is like $20,000 to $30,000 per ring. So, all of a sudden, you’ve got a very large investment,” Marshall explains.

Sollazzo adds, “Back in the day, you just went and bought the Seal Power ring. We knew what the metal ring was. You’d go to Seal Power, you’d tell them part number B-216, and they’d send you B-216. And you were happy. It’s not like that now. We have to design the ring and send it to the Teflon supplier. Not only are we sending it, TransTec is sending it and SAP is sending it too. No longer is there a single company source for a commodity that can supply all of the packagers. Our engineering team is constantly specifying parts that the purchasing people then find one or more sources of supply to acquire those components that make up our kits.”

While Precision International has grown its market share substantially in the AT aftermarket over the last several years, the company has also taken advantage of its packaging expertise to supply 300-400 assorted kits to General Motors (GMSPO); 75% are transmission-related with the balance being engine-related. In that role, the bill of materials is supplied by the OEM while the kit itself with complete installer instructions is the responsibility of Marshall’s team. Precision International has won six Supplier of the Year awards from GM in recognition of the creation, packaging design and delivery of those kits.

Marshall, Sollazzo and executive VP Frank Miller say that for the immediate future the company will continue doing what it does. The growth of EVs is certainly a long-range consideration; however, the internal combustion powertrains are going to be on the roads for a long, long time. For the foreseeable future, the company’s concentration will continue to be creating and supplying kitted component solutions to serve transmission rebuilders and their businesses.