“The great majority of the 150 people we employ are involved in the warehouse plant operations,” reflects Dennis Marshall, the owner/president of Precision International. “Those operations include shipping and receiving, quality control and the actual packaging of the kits we provide to warehouse distributors, production remanufacturers and to OE customers. Our warehouse manager, Jack Schweit, actually oversees everything that takes place within the facility itself.”

Marshall observes that sales, purchasing and development teams are all focused on putting the orders and the means to fulfill those orders together so that the plant can produce just what customers are wanting, just when the customers wants it and at a price the customers are happy with.

Schweit describes the process saying, “When the kits come through the development process, I’ll get a heads-up and we start making room to store the parts those kits require. That’s becoming more and more the challenge as we’re running out of room with more than 35,000 different part numbers in our warehouse.

“In addition, there are packaging considerations for some new kits. There may be something like an oversized piston, for instance. Early on we need to start planning a packaging solution whether it means new boxes or whatever it’s going to take to get all those parts into a single package. Once purchasing has sourced the components we will actually put a prototype kit together to make sure that everything’s going to fit as expected. All these things have to happen before we put the kit on the line and start assembly.”

Also needing storage in the facility are sufficient inventories of finished kits for about 450 different transmission units. There are many more than 450 when one considers that there are master, banner and overhaul variants as well as private labeled versions and possibly additional versions packaged for production remanufacturing facilities, Schweit said.

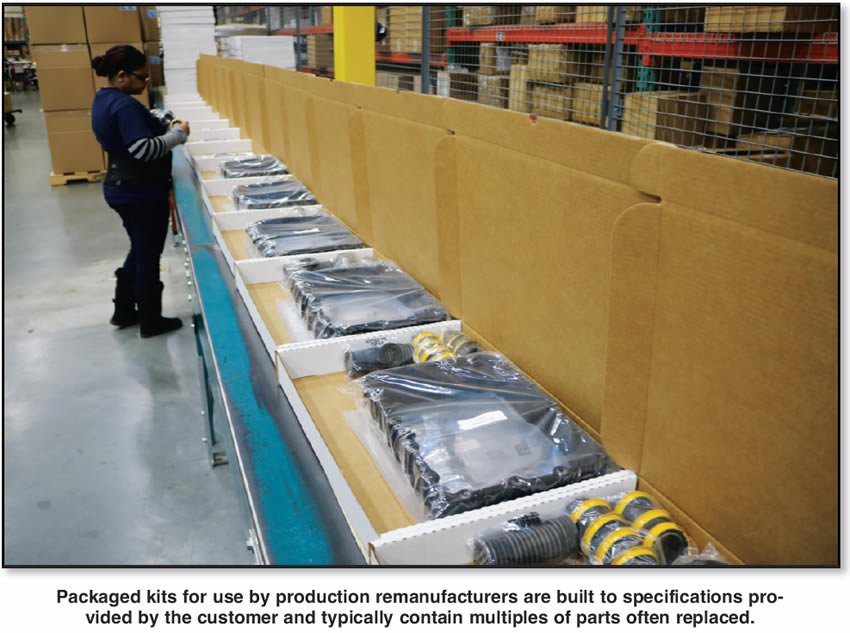

Precision Vice President of Sales John Sollazzo explains that maintaining large quantities of both individual components and finished packages in inventory is one of the realities of doing business in today’s marketplace. And, he says that both customer expectations and the physical makeup of parts have greatly changed over the years. “The responsibility for packaging the overhaul kits has, over the years, moved from the distributors to us. Like us, the distributor is limited on what his shelves will hold. Today, that distributor relies on us to maintain an inventory of all those parts, to box them into a kit and to be able to ship them immediately.

“Originally, the main Precision International product line was the traditional paper and rubber kit. In that kit you wouldn’t find things like oil seals or sealing rings. The parts distributors would source those items directly from the suppliers. As time went on, distributors wanted us to package an overhaul kit with the sealing rings and metal clad seals included. Then molded pistons came out and we needed to find a way to include maybe six or eight of those into the bag. Sometimes that doesn’t work so we have to box the kit.

“For anything new that comes out, domestic or import, we offer banner and master kits as well because distributors do not want to have to bring in case lots on plates for limited sales, they count on us to do that for them, in the form of masters and banners.”

“So, Jack and his people not only worry about the 70 or 80 parts required for the paper and rubber set or overhaul kit on a given transmission, he has to find space to store the pistons and clutch plates and everything else we need to package an overhaul version, a banner version and a master version of these kits.”

Schweit adds, “There’s nothing hard and fast but we’re probably bringing in three or four new and/or revised kits every month. What we most need to see in advance is the biggest part and the heaviest part, as those are going to be the main things that are determining the requirements for packaging. My first consideration is to look at a new kit and try to find something similar that we already have in the line. We look to see if we have a box that will work and a board that we’re using that could hold the clutch plates and so on.”

“There are transmission components today that didn’t exist a few years ago – components that need to be included in the kits we produce,” continues Sollazzo. “For instance, molded valve body plates and some of the General Motors units have these big molded gaskets that can’t be folded or just put into a bag. All of this takes place amidst a concern for the cost of the packaging. We rely on some of the companies that supply our boxes to help come up with new packaging schemes. In most instances we’ll mock up something and then have them look it over and see how they can provide that. At the same time, we have to stay cost competitive with other packagers.

“When we introduce a new kit, Jack is getting a bill of materials. Jack then takes those requirements and creates the packaging that will be required. If there’s something out of the norm, then Jack must come up with innovative packaging that not only will keep the components together without damage but is also affordable.”

Vin Soviero, who oversees technical and engineering, says that he will try to get advance notice to Schweit’s team when there’s a particularly large or heavy part that may require newly designed packaging.

“We examine the part or parts and then we have our people review and offer their input and maybe we’ll tweak it a bit more before we settle on how we’ll package it in full production. As time goes on we get better and the packaging takes place on one of our four assembly lines at a faster and faster pace,” Schweit says.

Sollazzo continues saying, “In today’s market we have to keep finished inventory on the shelves for both our Precision line and private label kitting we contract as well. We have to project the usage of each of those and keep our finished-goods shelves stocked so that when we get an order the people can pull those kits off the shelves and ship them immediately. Then we will restock the shelves from the production line.

“It’s a competitive advantage to be able to ship a major order complete within a couple of days of receipt. We have developed business with production reman facilities and have had to learn their preferences. Our customers know that when we get the order we’ll be shipping it the next day with everything they need; this helps them with inventory control and avoids lost sales.

“Our world and our work are different today. In the old days we used to set up for the 700-R4 and run packaging on those kits for the entire week. Now it’s two or three assembly lines set up to run a bunch of stuff because we may need a few hundred of this and 50 of those and a smaller private label kit that are needed right away.

“There are a lot more transmissions now, each used in fewer vehicles than in the past. We might set up to run the 4L60-E for a day, but past that we’re mostly talking short runs. Sometimes it takes more time to turn the line over from packaging one kit to the next than it takes to actually package what we need that day.”

“Very true,” says Schweit. “We run the kits that we have to have to keep up with our aftermarket customers and when we’re finished with those we go back to packaging for GM SPO. The OEM shipments typically take place on Wednesday or Thursday so we’re mindful of a deadline for completing those orders throughout the week.

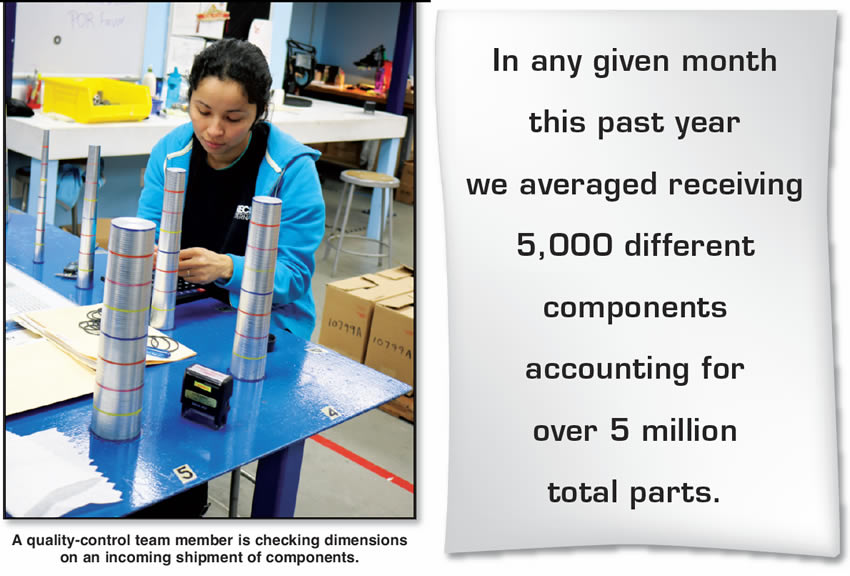

“In any given month this past year we averaged receiving 5,000 different components accounting for over 5 million total parts. Each incoming part is checked for accuracy and then the quality control people sit down and sample the part to make sure that all the dimensional and materials specifications were as ordered. That’s only the first of many checks that the quality control department is conducting. They sample sub-packages to make sure the correct count or the correct components are going into those bags. And we sample the full kits as they come from the assembly lines, again making sure that all the correct components are included. It’s a continuous job of making sure components are to spec and that each package has the correct components so that we maintain our reputation with builders who depend on having everything they need to finish a job correctly and on time.”

“We actively seek the input of guys who work at the shop bench,” Sollazzo says. We found recently that many of the builders didn’t like having all the sub-kitting to tear open. So, on popular transmissions like the 4L60-E we’ve condensed the packaging into fewer sub-kits as we assume that the builders understand how to build those and don’t need the help of breaking the components down into separate bags. In those cases we’ve condensed down to a single sub-package for the small parts. In the end it’s something that saved us time and effort.

“This is a perfect example of why we find it so very important to monitor what the customer is saying. We caught the customers’ concerns, we asked how we could fix it and the customers defined the solution; fewer bags in the overhaul kit.”

Concluding, Precision International General Manager Frank Miller says, “I think that as we move forward the most important habits we can apply to our continuing success will be to combine our vast knowledge and experience in packaging with the concern and flexibility that it takes to discover and react to what our customers need.”