The complaint

A 2005 Ford F350 with the 6.0 liter diesel engine and 5R110W transmission has set a P0753 “Pressure Control Solenoid A – Electrical Fault” code and a P2700 “Transmission Friction Element A – Apply Time Out Of Range” code. After a prolonged drive time, DTC P0752 “Pressure Control Solenoid A – Stuck On” and P0973 “Pressure Control Solenoid A – Circuit Low” also set.

The cause

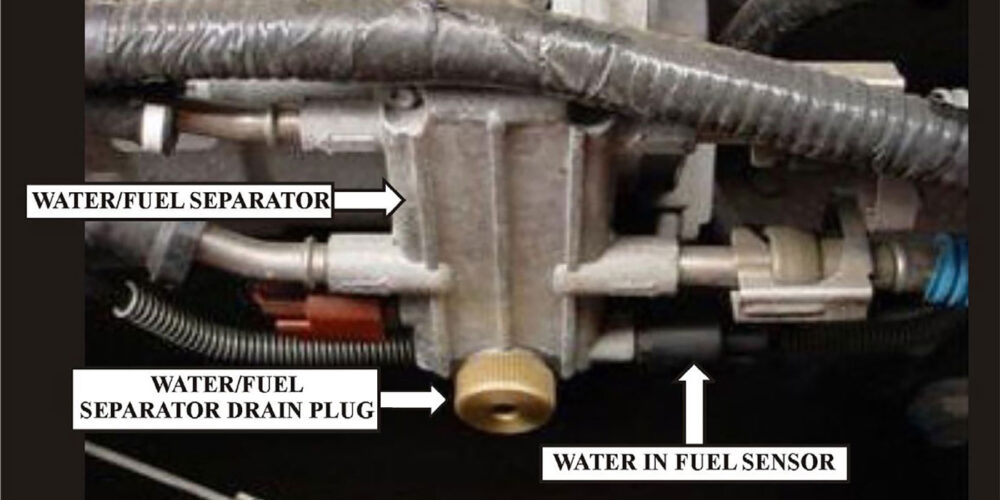

The C138E connector at the PCM was soaked with diesel fuel and the PCM contained about a pint of fuel. The PCM is mounted on the driver side inner fender and the C138E wire harness is routed down, alongside the left side frame rail below the diesel fuel water/fuel separator. Located in the water/fuel separator is the “water in fuel sensor” which was leaking diesel fuel. The diesel fuel leaked onto the C138E connector wire harness, which then wicked the diesel fuel up through the harness and into the connector and the PCM.

The correction

The PCM had to be replaced due to internal damage caused by the diesel fuel as well as the “water in fuel sensor” which is located in the water/fuel separator—refer to Figure 1, above. To remove the “water in fuel sensor,” disconnect the connector, remove the retaining clip, rotate the sensor 1/4 turn counterclockwise and pull it out of the water/fuel separator. Reverse the procedure to install, lubricate the sensor o-ring, a new retaining clip is included in the package—see Figure 2.

Note: It would be a good idea to drain the water fuel separator at this time due to the fact that it is neglected and could cause the “water in fuel” lamp to illuminate sometime after your repairs are completed. The drain plug is located in the lower center area of the water/fuel separator. A drain bucket will be needed; remove the drain plug slowly or the technician will be the recipient of a diesel fuel bath.

The wire harness and C138E connector were cleaned and reused. The DTCs were cleared and did not return.

Service information

6.0L Diesel Water In Fuel Sensor: 6C3Z-9C264-A

Read more articles in our Transmission Tech/Talk series here.