It’s no secret that the auto industry is making big moves these days, but while a lot is new, one thing that never changes is that the men and women servicing vehicles need to be learning almost constantly in order to do their jobs safely and effectively. Everybody knows not to touch hot exhaust parts, unplug ignition wires bare-handed or wear a necktie around spinning fans and pulleys. A few decades ago, airbag systems surprised a few techs before it became common knowledge what those yellow wires running around the car did. And today, we can add stop-start accumulators to the list of new hardware that bites back when disrespected.

When I was a teenager, I drove a car that would occasionally shut down when I pulled up to a red light or stop sign. I didn’t really know why — it just happened sometimes. If I was lucky, I could restart the engine and move along without too much delay.

My car was probably just ahead of its time because, nowadays, lots of cars and trucks are built to do this on purpose, all in the name of saving fuel. For quite some time, there have been some hybrids with electric motors that are big enough to get the car rolling before the engine starts. But in more recent years, cars equipped only with a gas engine have also begun shutting off the engine when the vehicle comes to a stop.

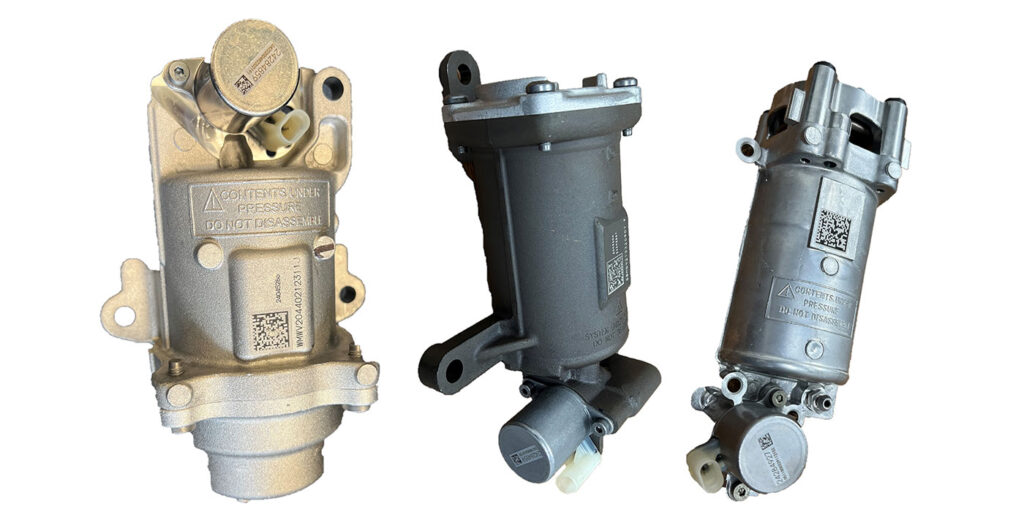

Since it’s the engine that drives the automatic transmission pump, shutting the engine off usually requires additional hardware to make sure the transmission has pressure available in a hurry when it’s time to move again. There have been a few methods developed to accomplish this. For example, some cars had electric pumps that would maintain transmission pressure while the engine was off, but a few years ago GM came up with the idea of storing pressurized ATF in a spring-loaded stop-start accumulator. There are at least three variants of these: one for the GF6 (6T40), an internal unit for the 8L45 and 8L90, and one that GM and Ford share for the 9T50/8F35 transmissions.

Read more columns from the TASC Force Tips series here.

For the most part, the accumulator just sits on (or in) the transmission, very quietly doing its job of accumulating pressurized ATF while the engine runs and the transmission pump spins until it’s fully charged. When the engine shuts down, it can hold the pressurized oil for quite a while — a surprisingly long time, in fact. And when the driver releases the brake, the solenoid valve opens to release all that oil very quickly, pre-pressurizing the system so the clutches have the torque capacity needed to pull away smoothly from a stop. This usually happens in just a few tenths of a second, which is much faster than the transmission pump would have been able to supply pressure to the system.

However, the same characteristics that make these accumulators so good at their job also gives them some potential to injure the folks who handle them. You might have guessed from the earlier description that they pack a bit of a hydraulic punch. When they’re off the transmission, it still only takes that same .2 to .3 seconds to spit out around 100 mL of hot, 200+ PSI transmission oil. And if you try to remove the solenoid valve while the unit is charged, you get a one-two combo of the valve becoming a missile with that jet of hot oil right behind it.

That should already be more than enough reason to use appropriate caution around these, but just in case you need a little more, there are also a couple of really beefy springs inside that are compressed even when the accumulator is completely discharged. Imagine that the coil springs on the front of the car had teenage kids; that’s about the size we’re talking about. They’re much larger than anything you’ll see in a valve body, and they’d love to come out and meet anyone who dares to remove the cover screws.

The bottom line is that stop-start accumulators must be handled properly in order to avoid injury. In all cases, it should be considered a requirement, not just a suggestion, to read and fully understand the appropriate service manual procedures for safe removal, discharge and handling of these units. Furthermore, it’s imperative to respect the warnings NOT to attempt disassembly — there’s a good reason those are cast into the hardware. There is more than enough fluid, thermal and mechanical energy in these to send a tech to the ER if he or she makes the wrong move.

Matt Allbert is an aftermarket engineer at Solero Technologies. Solero is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of industry technical specialists, transmission rebuilders and Sonnax technicians.