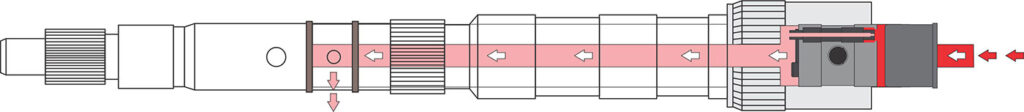

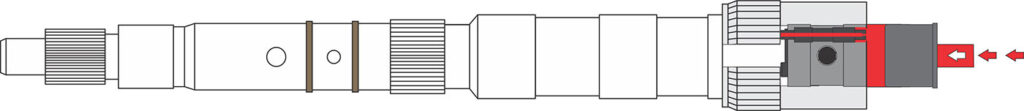

The Chrysler 948TE transmission (seen in the above image) stands out for its unique use of two dog clutches: dog clutch A and dog clutch F. Dog clutch A (Figure 1) is used to drive an annulus/sun gear while dog clutch F (Figure 2) is used to hold a double sun gear stationary.

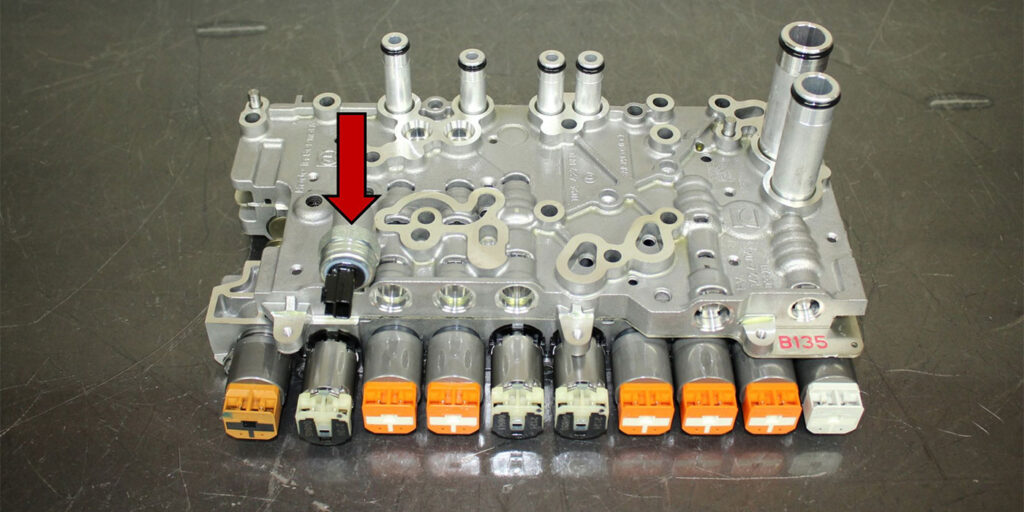

In a manual transmission, what’s called “dog teeth” are integral to a gear. A brass blocker ring is used to synchronize the slider into the dog teeth for a smooth transition into that gear without grinding. But the 948TE does not have a blocker ring to assist in the synchronizing of the dog clutch. The computer needs to do this work controlling the speed of these components during the application so that a smooth transition occurs. One of the ways this is accomplished is for the computer to monitor the position of the dog clutch; it does this with the use of a pressure sensor on the valve body (Figure 3).

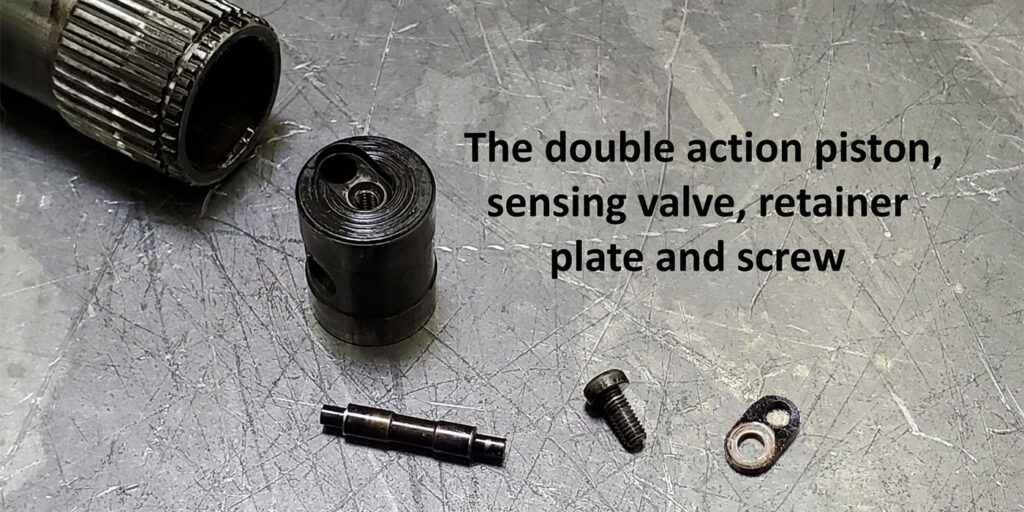

Dog clutch A uses a sensing valve located inside a double action piston to provide its position to the pressure sensor, while dog clutch F does not; it utilizes a much simpler sensing system by using a bleed hole in the piston. Dog clutch A being a bit more involved lends towards it not functioning correctly. And when it does malfunction, it can cause an intermittent loss of forward or a lack of any forward at all.

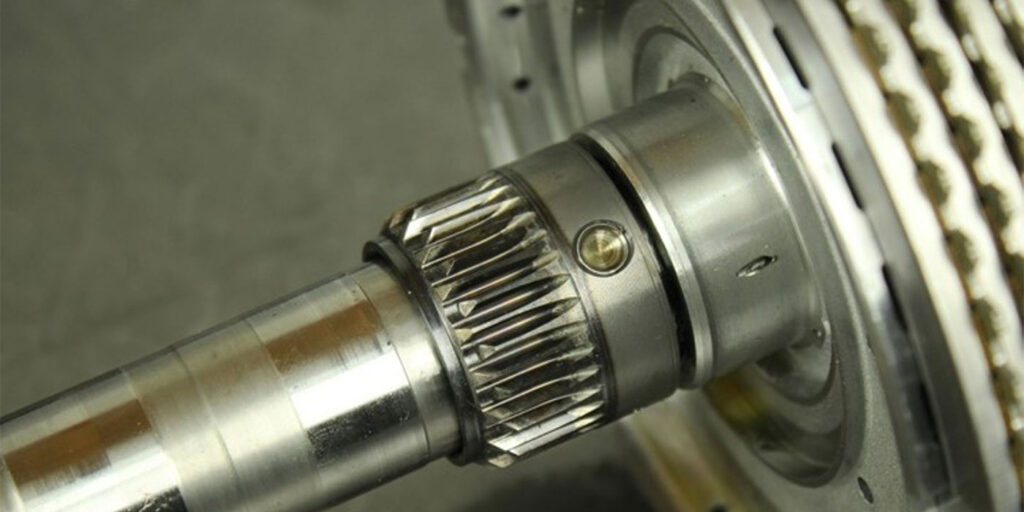

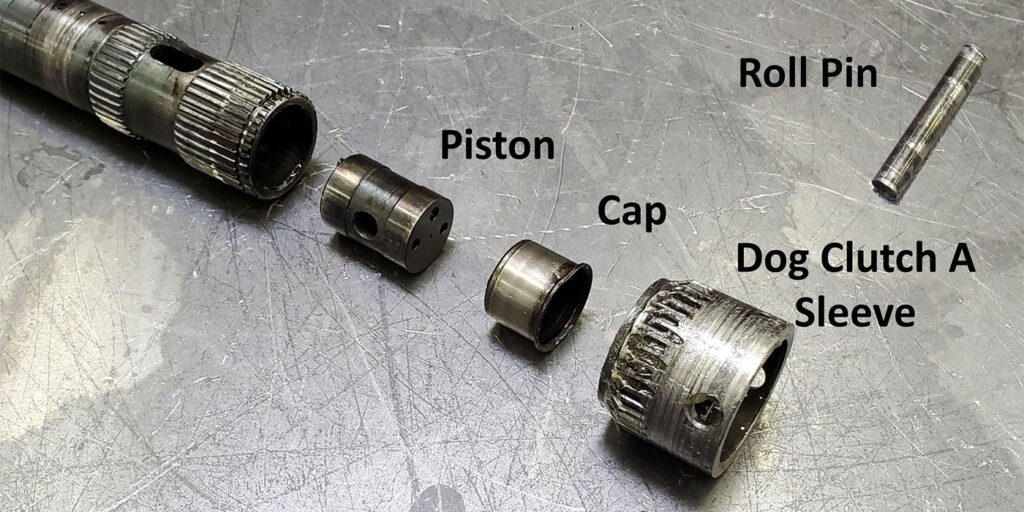

Dog clutch A is a sleeve with both internal and external splines. The internal splines are permanently splined to the turbine shaft. It is attached to a double action piston inside the turbine shaft with a roll pin (Figure 4).

There is a slot in the turbine shaft this roll pin goes through, allowing the piston to engage or disengage the dog clutch. Inside this double action piston is a sensing valve (Figure 5).

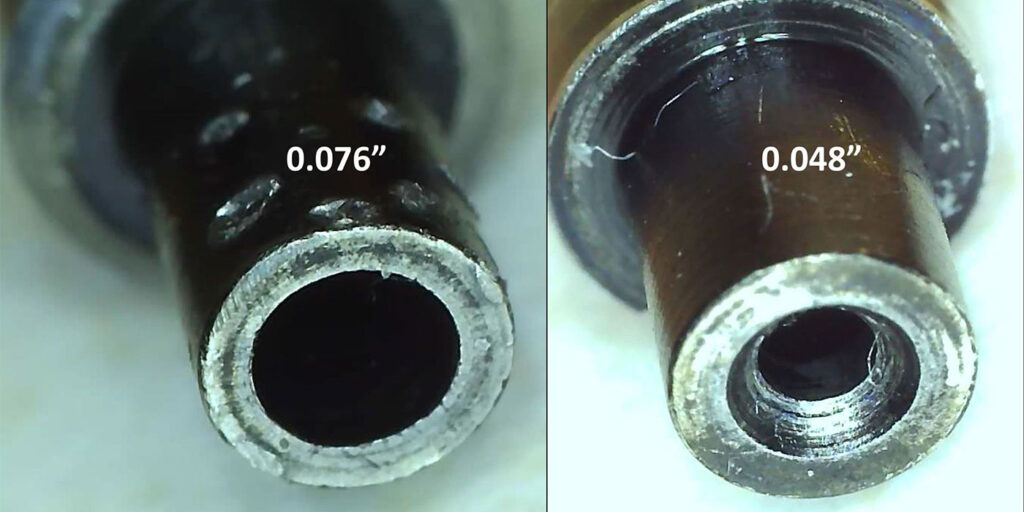

This sensing valve is held into the piston with a screw and cover plate. One end of this sensing valve is a 0.048” orifice while at the opposite end is a 0.076” orifice (Figure 6).

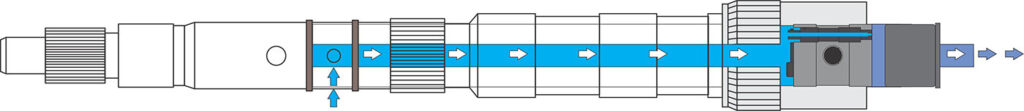

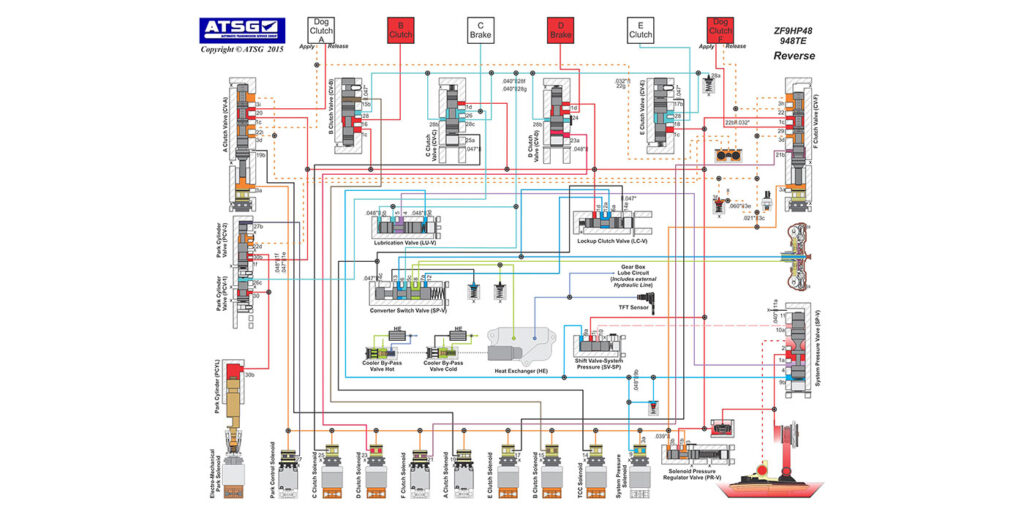

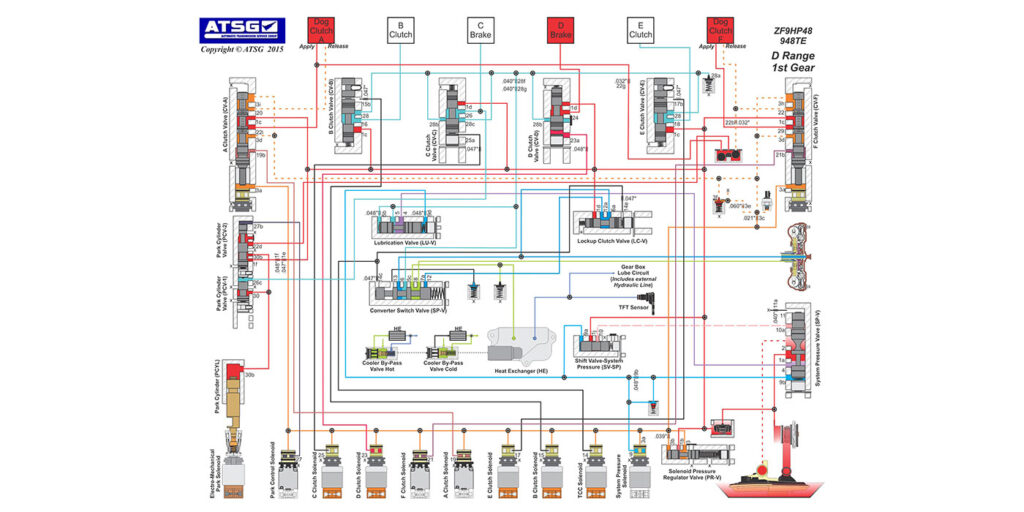

The leakage that passes through this valve as the piston is being applied is approximately 29 PSI and is monitored at the pressure sensor. Once the piston has fully engaged or disengaged the dog clutch, the end of this sensing valve is blocked and the pressure at the sensor goes to 0 PSI. This is how the computer knows when the piston begins moving the dog clutch sleeve, and when it has traveled its complete distance. To illustrate this process, Figure 7 shows the beginning of how the dog clutch sleeve is released.

As pressure is supplied past the sealing rings on the shaft, it travels down the center of the shaft where it enters the piston chamber. As it pushes the piston towards the release position, pressure also passes through the center of the sensing valve metering this oil to the pressure sensor on the valve body. Approximately 29 PSI is present at the sensor during this event. When the piston reaches its full travel where the dog clutch sleeve is released, the end of sensing valve seals against a retaining cap in the shaft (Figure 8).

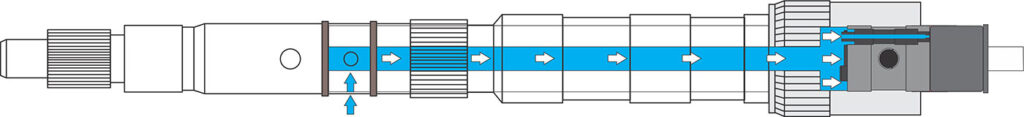

This drops the pressure at the sensor to 0 PSI, informing the computer that this shift event has been completed. The same process occurs when engaging the dog clutch sleeve. Pressure is supplied to the end of the shaft through the inside opening of the retaining cap (Figure 9).

As the piston is moved towards the engagement position, pressure is metered through the sensing valve, past the sealing rings on the shaft and into the pressure sensor on the valve body. Once the dog clutch sleeve is fully engaged, the end of the sensor valve is blocked and pressure at the sensor will drop to 0 PSI (Figure 10).

To see how this is represented in typical hydraulics, Figure 11 shows dog clutch A in the released position while Figure 12 shows it in the applied position. Dog clutch A is in the upper left corner while dog clutch F is in the upper right corner. Below dog clutch F you can locate the pressure sensor.

As you may have noticed by looking at Figure 4 previously, the dog clutch A sleeve has damaged splines as well as being overheated. This, or something worse, is what you may encounter when this system fails. In the dog clutch you see in Figure 4, the little screw that holds the sensing valve retainer plate to the piston was found to be loose. Sometimes this screw backs out enough to the point that its head snaps off. This hampers the full travel of the piston, keeping the end of sensing valve from being sealed off. When this occurs, a continual flow of pressure is supplied to the pressure sensor. The result is erratic sensor readings, erratic engagement of the dog clutch, and an intermittent or complete loss of forward movement—not to mention that some grinding will take place to add a little sparkle to the fluid.

As mentioned earlier, dog clutch F is a much simpler design. The double action piston and cover is located within the bearing support assembly as seen in Figure 13.

Built into the double action piston is a sensing hole rather than having a valve (Figures 14 and 15).

As the piston moves, it provides approximately 29 PSI to the pressure sensor. When the piston has reached its full travel, the hole is closed off by the cover on the top side and the housing on the bottom side. For this system to malfunction, piston and cover seals need to be compromised or clogging of the sensing hole would have to occur—and I have heard of neither of these things happening as of now. But one thing is certain: this is truly a doggy dog transmission.

Read more stories from our Technically Speaking column series here.