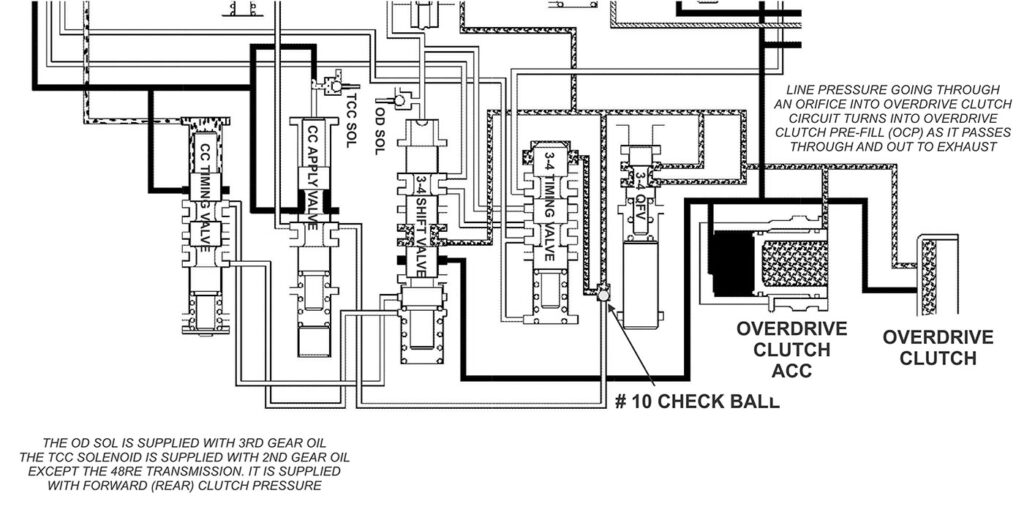

Twenty-five years ago, Chrysler introduced a 0.187-in. (4.77mm) steel, #10 check ball (figure 1, above) in the 42RE valve body which continued to be used throughout the entire RE series of transmissions (42, 44, 46, 47 and 48RE) as they were launched.

This small check ball is quite active, having several functions during the course of one complete drive cycle. The #10 check ball was implemented to ensure smooth sequential downshifts. These are its three basic functions:

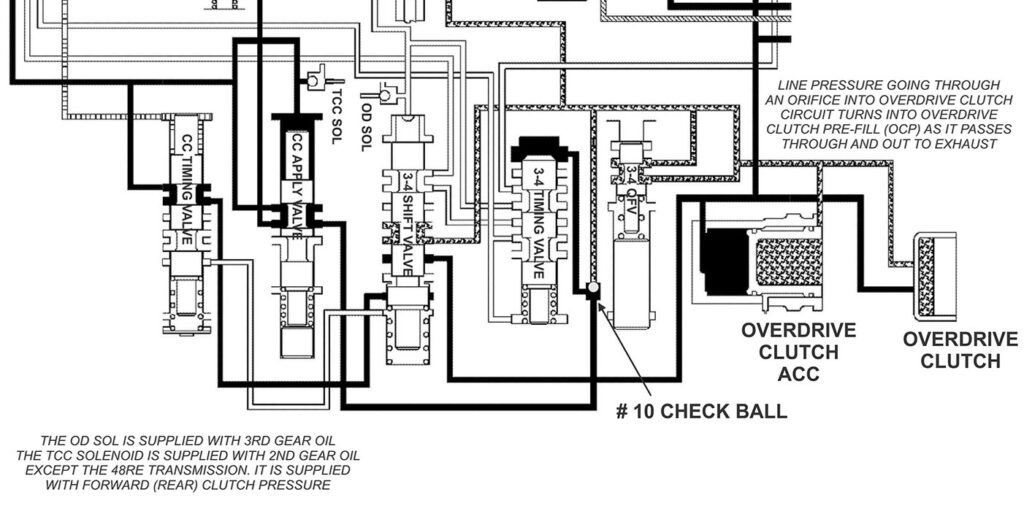

Function #1: When the converter clutch is off, it sends Overdrive Clutch Prefill (OCP) pressure (0-5 PSI) to the 3-4 Timing Valve while simultaneously blocking it from entering the converter clutch apply circuit (as seen in figure 2).

Function #2: When the converter clutch is commanded on before fourth gear, this ball will then block OCP pressure to the 3-4 Timing Valve, allowing pressure from the converter clutch apply valve to stroke the 3-4 Timing Valve (as seen in figure 3).

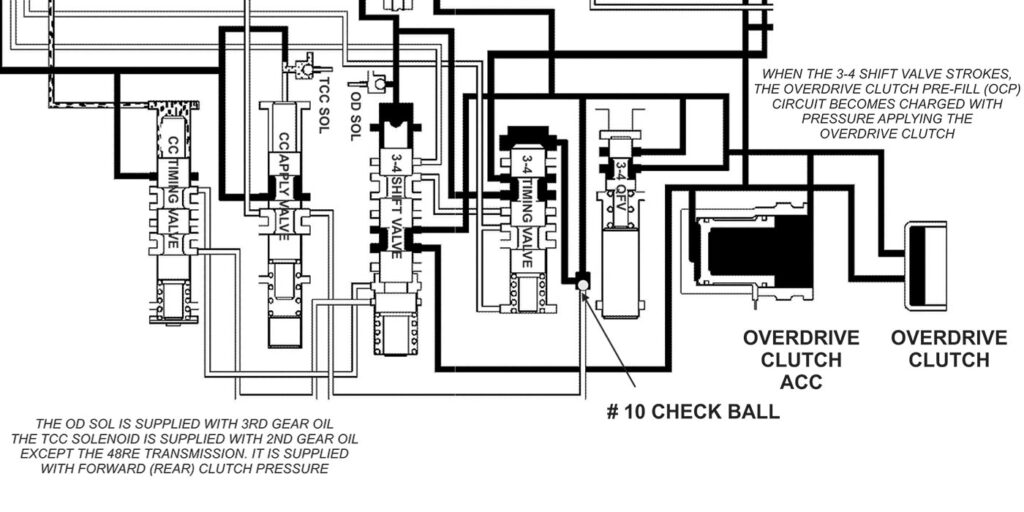

Function #3: When a shift into fourth gear takes place, Lock-up turns off and the Overdrive Solenoid turns on stroking the 3-4 Shift Valve. Once the 3-4 Shift Valve strokes, it fills the OCP circuit with pressure, applying the Overdrive Clutch. This same pressure is routed to the 3-4 Quick Valve, the Accumulator and the # 10 check ball where it is then sent to stroke the 3-4 Timing Valve (as seen in figure 4).

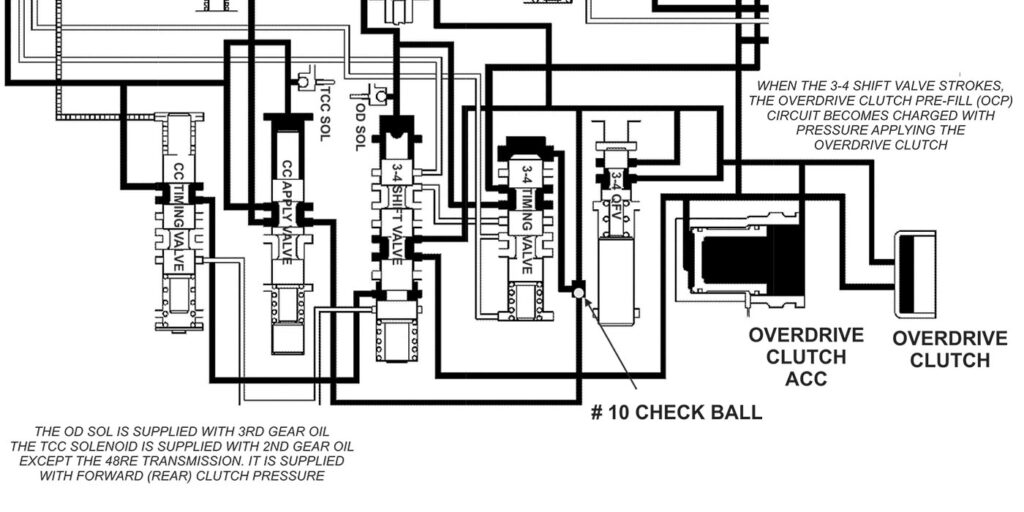

There is an additional hydraulic function that took place when this ball was added. It occurs when the converter clutch is commanded on in fourth gear. When the computer turns the lock-up solenoid on, it strokes the converter clutch apply valve. This charges a circuit that causes the converter clutch timing valve to stroke. The converter clutch timing valve then sends line pressure to the rear spool of the 3-4 shift valve (as seen in figure 5).

This is added insurance to keep the shift valve stroked. And again, all this is done to assist in providing a smooth sequential release of the converter clutch, followed by a downshift. It prevents the converter clutch from releasing on top of a downshift which would be felt as a harsh downshift.

Let’s now talk about one of the failures that can be experienced with this hydraulic system. The complaint that typically accompanies this failure is when there are no forced throttle downshifts when the transmission is hot. This complaint only occurs once the transmission has shifted into overdrive followed by the converter clutch being commanded on. The scan tool data reveals that at wide open throttle the lock up solenoid and the overdrive solenoid are being command off, yet the transmission remains in overdrive with the TCC applied. If you pull the shift lever from the “drive to the number 2 position” it will downshift to 2nd gear. A careful road test may also reveal that once the transmission is hot, the lock up clutch may engage after the 1-2 up shift.

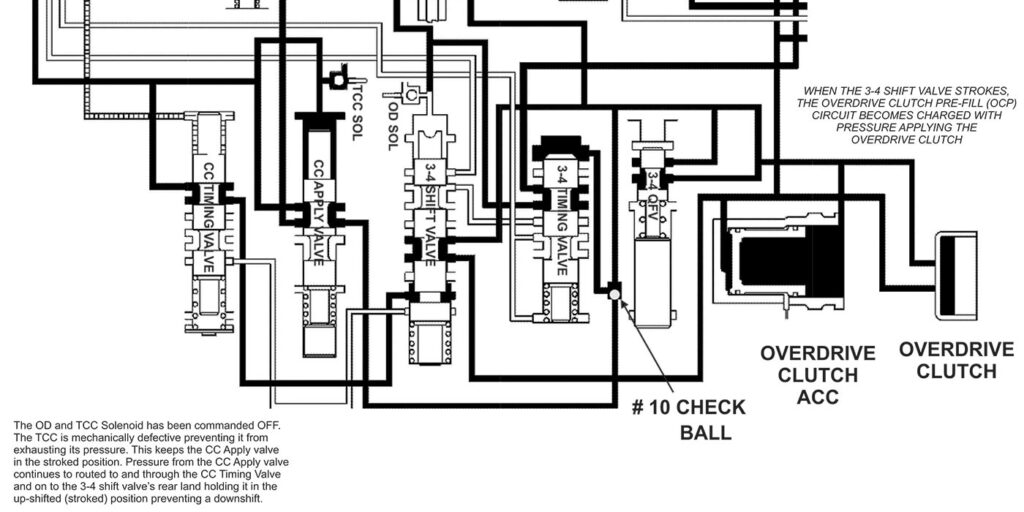

The cause is that the lock up solenoid has mechanically failed, preventing it from exhausting when it has been commanded off by the computer (as seen in figure 6).

This keeps both the converter clutch apply valve and 3-4 shift valve stroked in the upshifted position. The converter clutch switch valve is also kept stroked, keeping the converter clutch applied. By installing a new TCC/OD solenoid assembly, these malfunctions are resolved.