If you have ever watched the movie Forrest Gump, you know the quote, “Life is like a box of chocolates. You never know what you’re going to get.” That quote holds a lot of value in the transmission industry these days.

Transmissions may look the same from the outside, however, it is what is on the inside that can make a difference between a successful repair or a costly one. What am I talking about, you ask? Gear ratios.

The modern car is very integrated from one module to the next and from one gear ratio to another. When you are replacing parts, or the entire transmission assembly, you need to know what ratios you are removing so you can install the correct one. Otherwise, you may create a problem that you did not have with the original transmission.

One example was a customer with a 2015 Jeep. This vehicle came in with a P0215C code and a rough coast downshift. This vehicle was fitted with a 948TE 9-speed transaxle with a 3.2L engine and a 4WD drivetrain. It arrived from a local dealer where they installed a used transmission. The used replacement transmission solved the unknown problems with the original transmission; however, it now had a recurring coast downshift clunk and a P0215C with the replacement transmission. It did not have these problems with the original transmission according to the dealership technician.

Diagnosis

The first item on the diagnostic hit list is the P0215C. The downshift clunk is most likely being induced from the DTC P0215C which is not allowing full adaption with the code present.

DTC P0215C definition: Vehicle speed to wheel speed correlation out of range.

The definition means that the powertrain control module (PCM) has detected a discrepancy between the vehicle speed sensor and one (or more) of the wheel speed sensors.

The vehicle speed sensor and the wheel speed sensor are both intended to detect vehicle speed. The PCM is constantly monitoring vehicle speed when the vehicle is moving forward. The individual wheel speed sensors are constantly monitored by the anti-lock brake control module (ABCM), or electronic brake control module (EBCM). These two controllers share data via the CAN Bus network and compare the signals anytime the vehicle is in forward motion.

If either controller detects a discrepancy between the vehicle speed and the wheel speed that exceeds the maximum threshold, the code P0215C will be set and stored. Also, the malfunction indicator lamp will be illuminated.

Causes for the P0215C code may include:

- Excessive metallic debris on transmission speed sensor

- Defective wheel speed sensor

- Cut or damaged wiring or connectors

- Broken, damaged or worn reluctor gear teeth

- Mechanical faults with transmission gearing

- Faulty PCM, ABCM or EBCM

- Interference or damaged wiring in the CAN Bus system

First things first. Now that we know the definition of the P0215C code, and what will set it, I asked the shop tech to provide some scan tool information. In this example, the scanner data graph for the vehicle speed sensor is running slower than the wheel speed sensors. I researched my archive of Snap-On data movies for this transmission and found that the readings indicated were incorrect. This was the first clue into the P0215C code. The vehicle speed sensor assembly reads off the teeth on the final drive pinion gear.

To further complicate matters, these vehicles are available with several powertrain configurations and ratios:

- 2.4L FWD

- 2.4L AWD with single speed transfer case (PTU) referred to as “Active Drive”

- 3.2L FWD

- 3.2L 4X4 with 2 speed transfer case (PTU) and 2 speed rear differential

- 3.2L 4X4 with 2 speed transfer case (PTU) and 2 speed locker rear differential

- 3.2L AWD with single speed transfer case (PTU) referred to as “Active Drive”

Both the 2.4L and the 3.2L transmissions are available with a trailer tow option. Vehicles equipped with the trailer tow option will have a lower transmission final drive ratio. The 2.4L engines have a final drive ratio of 3.73. The 2.4L engines, with the trailer tow package have a final drive ratio of 4.08. The 3.2L engines have a standard ratio of 3.25, and the models with the trailer tow option have a 3.51.1 ratio. The rear differential is also available as a locking type as well. Please keep in mind this information is for the 2015 model year only. The ratios and options may vary based on the production year and model.

Once the diagnostic investigation was under way, I looked up the part number for the transmission assembly by the VIN number. The search results indicated that there was only one selectable part number listed for this VIN code, it had a 3.51 ratio. The listing also had the part number for the 3.21 ratio unit as well. The 3.21 unit could not be selected from the list, which indicated to me that it was not the correct transmission for the VIN number entered into the search. To satisfy my curiosity, I did another search without the VIN. I discovered that I could choose either ratio; however, I was prompted to order by the VIN.

Service transmission part number assembly: RL225760AP 3.21 Ratio

Service transmission part number assembly: RL225761AP 3.51 Ratio.

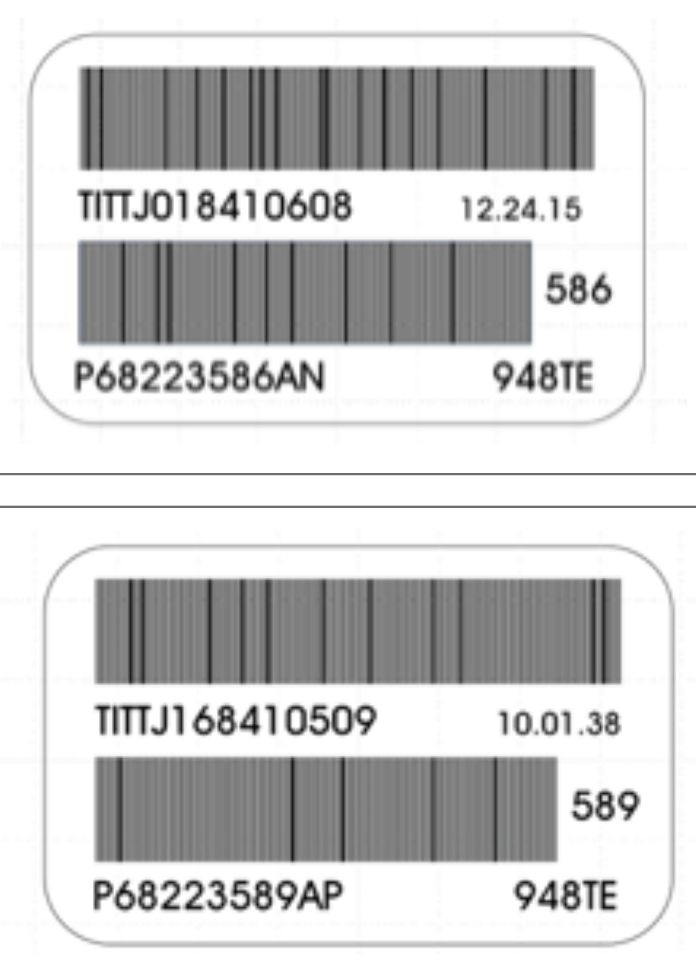

Fortunately, the repair shop was given the original transmission. The ID numbers on the tags (Jeep only) were different between the original transmission and the used replacement as seen in Figures 1 and 2.

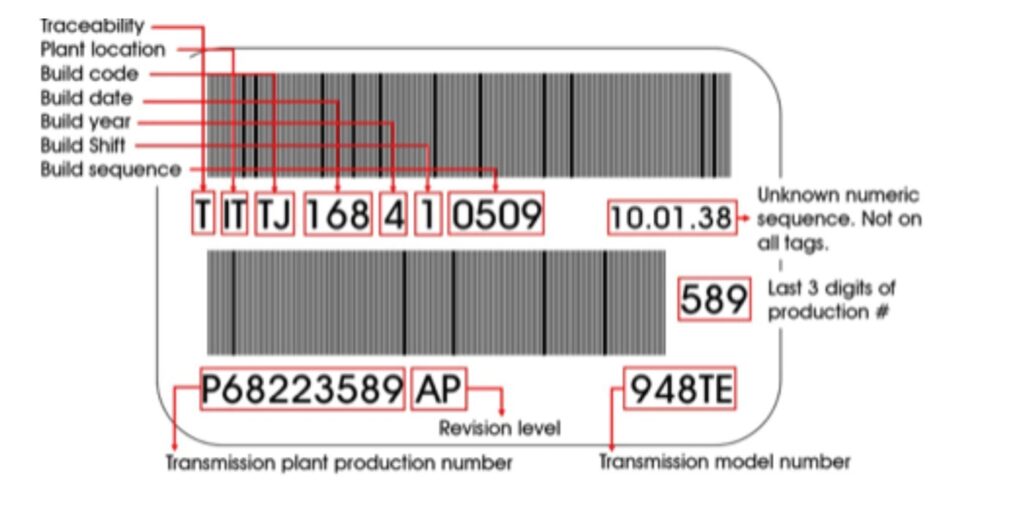

In my search efforts to determine what the meaning of ID tag numbers were, I learned what you can see in Figure 3, at the top of the page).

The transmission plant production number on the tag is the number that is associated with the service replacement transmission part number listed by FCA. A search of the service replacement part number, not the plant production number, indicated that the vehicle had the wrong ratio installed. The used transmission that was installed had a 3.21 ratio when this vehicle required a 3.51 ratio. This tells us the vehicle was built with the trailer tow option.

The correct ratio transmission was installed, the rough downshift and the P0215C was eliminated.