Tech to Tech

- Subject: Technician safety

- Essential Reading: Everyone

- Author: Brian Manley

Basic steps or precautions can save your shop unwanted injuries

A recent newspaper column circulating on the Internet caught my eye with the headline “Mechanic Injured When Garage Burns.” How could I not read it! The story goes, “The employee was trying to cut a gas tank off a car and it fell on top of a lamp, which caused a spark and there was still some gas in the tank that caused it to catch on fire.” Thirty-six firefighters were needed to extinguish the blaze, which left the building a total loss and the technician with second- to third-degree burns. That is the part that hurts – literally.

Yet another recent headline reads “Officers Revive Home Mechanic After Car Falls on Him.” All you need to know about this story is that the young man was replacing a starter motor while the car was propped on a scissor-style jack – with no jack stands. These reports, along with a recent flesh wound I sustained, have me pondering the safety of my shop – and yours.

As a young tech, I witnessed my co-worker welding a piece in a vise on a bench with an oxyacetylene welder, and when he moved the torch to the side and lifted his mask, he inadvertently set the solvent tank on fire. That was a fast flash of fire, a frantic race for the extinguisher and a quick decision to put him out, then the solvent tank. No major injuries, thank goodness.

How honest are we with ourselves in regard to our safety practices? Do we occasionally find ourselves cutting corners or ignoring safety practices in our bays?

According to the U.S. Department of Labor, from 2003 to 2005, 147 mechanics lost their lives on the job. In 2005, non-fatal injuries and illnesses led to mechanics missing 15,680 days from work. The No. 1 event or exposure for workplace fatalities during 2003 to 2005 was contact with objects and equipment. The primary sources of fatalities were vehicles (44.9%), bullets (19%), and parts and materials (10.2%). Sixty-six cases were cited as ones where the vehicle was the source of the fatality. Of those cases, 40.9% were transportation incidents and 34.8% were from being struck by falling objects, such as a car falling off a lift, rack or jack. Rounding out the list, asphyxiations and suffocations comprised 15.6% of the fatalities to mechanics during this two-year period.

If we take the bullets out of the equation – and I almost never service a vehicle with those anymore – those are some sobering statistics.

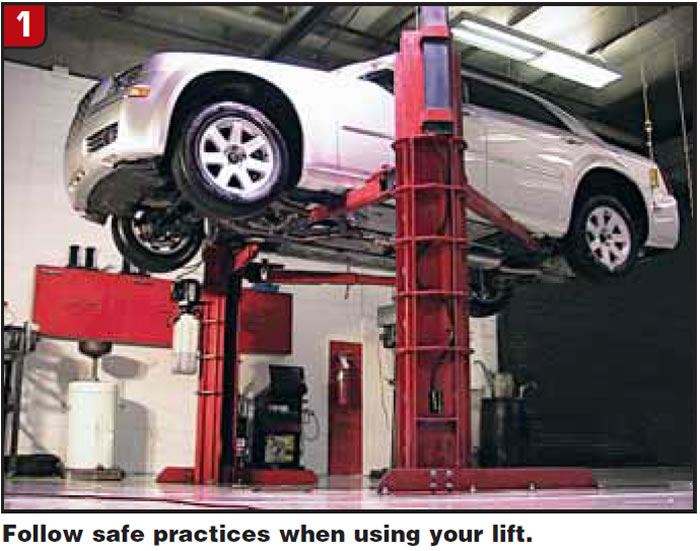

Let’s begin with our lifts. How many of you are using a vehicle lift with frayed lift cables, leaking hydraulic cylinders or missing lift pads? I have distinct memories of a shop long ago where the hydraulic, center-post, in-ground lift would “shoot” up while raising a car when the lift reached three-fourths of its travel! It would also “drop” several inches when lowering; a scary time, and a lift that was long overdue for service!

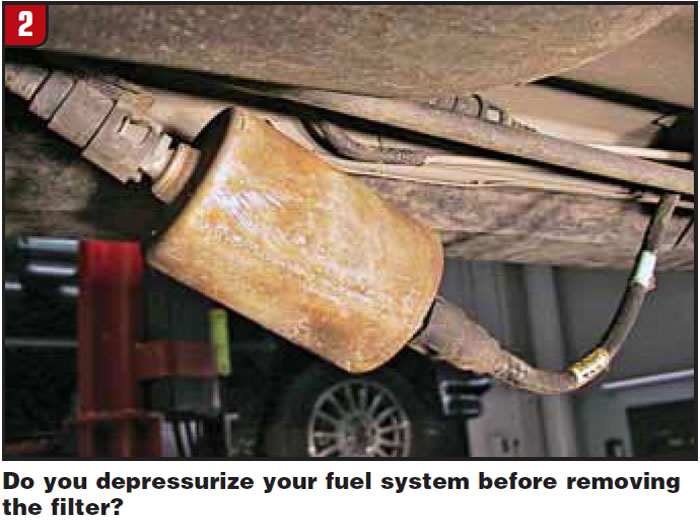

How many of you depressurize the fuel system before popping off those retaining clips and letting a little (or a lot) of fuel squirt? When it does squirt, is it hitting you in the eye, or, worse yet, do you have an older, hot, incandescent light bulb hanging nearby?

How is your personal protection? Safety glasses (and safety glasses that fit over regular glasses) are often optional in shops, and used only during grinding. That being said, have you, or anyone you know, ever had a serious piece of metal or debris cause discomfort or a trip to the E.R.? How many of you are using fluorescent lights (to minimize risk of fire)?

In our training program, we require that all techs-in-training wear safety glasses. We are constantly checking (and adjusting) jack-stand placement and lift-arm location and looking for oil spills on the floor. We switched to an aqueous parts-washing solution for its healthier-than-the-old-solvent feature and. in hindsight, for its non-flammable qualities as well.

When you are servicing brakes, are you practicing the “no visible dust” rule for brake service? Are you taking every precaution to avoid inhaling harmful dust and chemicals? The older I get, the more I worry about the long-term effects of those chemicals I had my hands in, and the brake dust that I inhaled so many years ago.

Are you using the right gloves in the right situations in your shop? As I write this, my wound is still healing (and it got me even through my glove!). How up to date is your first-aid kit? I discovered that after my cut, we were running low on antibiotic cream and Band-Aids, so I restocked. I shouldn’t have had to have a bloody reminder to check our stock of bandages.

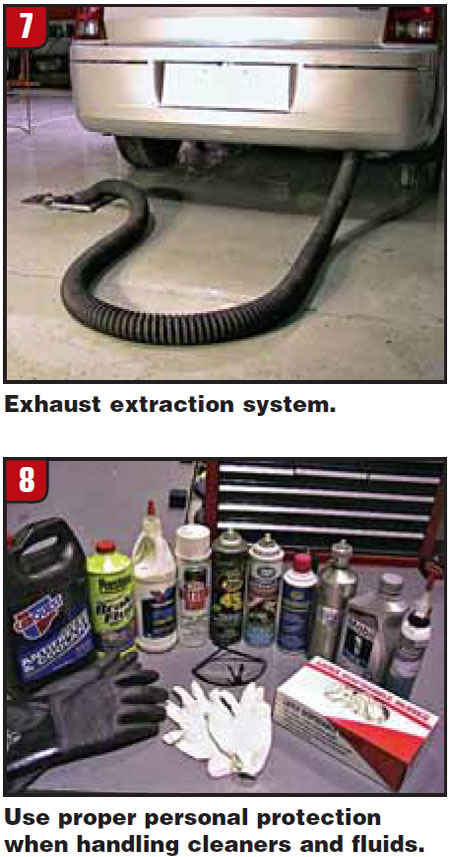

Do you ever run a vehicle for “just a little while” in the shop and suffer a headache as a result? I see technicians do this, and the carbon monoxide affects everyone in the shop and lingers. Some hoses push through a garage door, and others, like ours, have an in-ground system with an exhaust fan. Yes, we sometimes still have our young techs “forget” to turn on the exhaust fan!

As technicians, we all have a responsibility to maintain a safe working environment, free from falling objects and as many dangerous chemicals as possible. It makes sense to take a few minutes to discuss this with your co-workers and perform a quick inspection of:

- Clutter

- Oil spills and cleanup procedure

- Eye protection

- MSDS sheets

- Exhaust-system integrity and correct tailpipe adapters

- All lift components

- First-aid kit

- Grinder rest, stone and face shield

- Adequate supply of protective gloves

- Brake-parts-washer function

- Oxyacetylene-torch hoses and gauges

- Power and extension cords

- Floor jacks and stands

- Droplight type and function

- Fire-extinguisher location and inspection date

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation board of trustees. He can be reached at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.