Tech to Tech

- Subject: Tips of the trade to help technicians

- Essential Reading: Diagnostician, R & R

- Author: Brian Manley

With close to 30 years of automotive service behind him, this technician and instructor shares his best tips of the trade

Since we are part of an automotive training facility, we must enforce all safety protocol in our shop: Safety glasses and hearing protection are mandatory, aqueous parts cleaner has replaced the “good” stuff, and our shop environment should be as safe as we can make it.

During certain lessons in our training facility, we impart many tips and tricks to our students. Often simple and always handy, these useful “nuggets” reduce headaches, save money and keep us safer. I’ve accumulated these tips during the 15 years that I worked as a full-time technician as well as during the 14 years that I’ve been an automotive instructor. Over the course of my automotive-service career, I have been fortunate to pick up many of these helpful hints from forums, fellow technicians and publications.

Buy bungee cords!

We use these for hanging calipers during brake jobs, and also to secure our alignment heads onto wheels during four-wheel alignments (Figure 1). Since doing this, we have not had one incidence of an expensive alignment head hitting the floor, but they have popped loose due to poor attachment by the tech! Buy a bunch of these and keep ’em handy.

Roll down a window

When you pull a vehicle into the shop, and the keys are inside, roll down a window. Trust me – I learned this the hard way. I started rolling down the driver’s window until one day the window fell off its track and went to the bottom of the door (whoops). So now I roll the driver’s window down a couple of inches and test its stability, or I just pick another window that has a higher probability of functioning.

In addition, we teach young techs to sit in the driver’s seat with their foot on the brake before starting the car, instead of reaching through the window to crank it. Why? Remember those defective parking pawls that would allow an automatic transmission to “slip” into reverse when you slammed the driver’s door?

Buy some sticky tape

Often called “Dum-Dum,” this is the sticky, black tape that is used to bind expansion valves to evaporators. I put a small piece of this inside a universal socket and then insert the nut or bolt into the socket (Figure 2). Presto! The nut or bolt won’t fall out. This can be used on the outside of a “floppy” universal to stabilize it as well. You can Google “Prestite” and order some online. Discarded latex gloves can be cut up and used for this purpose as well. Just insert a piece into the socket to provide some gripping ability for the bolt.

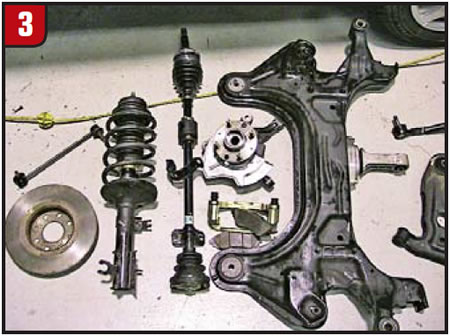

Take digital pictures

This is easy and inexpensive to do these days. My wafer-sized, 1GB “SD” card holds about 1,000 pictures. You can use it to show before-and-after pictures for a repair, or to show orientation of wires, hoses or connections to an engine. For example, Figure 3 shows a pile of steering and suspension parts for use in comparison with new pieces, showing the customer what had been replaced. The last engine swap we did, we took “before” pictures of the engine bay from the front and both sides to aid with hose and wiring-harness routing; it sure saved time when reassembling!

Buy touch-up paint or white-out

I own a bottle of white touch-up paint that I use for marking crankshaft pulleys and timing marks on camshaft gears, distributor rotor-to-base alignment and phasing brake rotors to their hub.

Prevent visible dust

We preach the “no visible dust” rule in our shop; however, we still hear about techs using blow guns on occasion in local dealerships where our students are interns! We recommend “washing” brake assemblies before removing the drums.

I grew up with my hands in Stoddard solvent – you know, the “good” stuff – but we now use only aqueous parts cleaner, including the washer for brake jobs, which slides right under the axle (Figure 4).

Keep track of your gaskets and fluids

Very basic, but extremely important: Double-check your gaskets on your oil filter and drain plugs. I always match my old filter to my new one face to face so I can see if the gasket is missing, and also to see if I have the correct filter. I still catch a few gaskets sticking to the block this way. In addition, we keep a set of new drain-plug gaskets, and plugs with integrated seals, ready for replacement. Some techs will put the drain-plug wrench in plain sight, or in their pants pocket, until they have tightened the plug.

We also pull our dipsticks halfway out of their tubes before fluid service, so we have a good visual before closing the hood that we may have forgotten to fill the crankcase with oil. Some techs will pull the dipsticks out and lay them in plain sight under the hood instead.

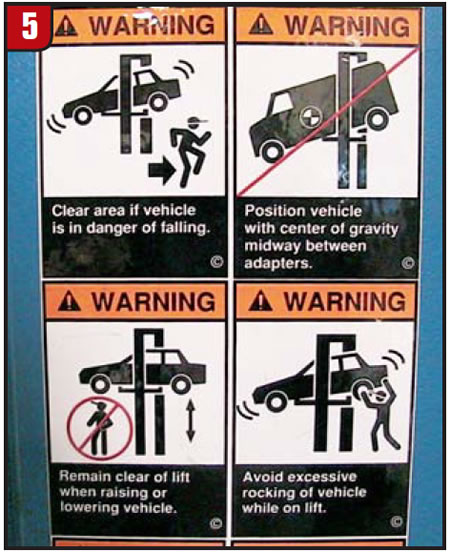

Beware of the dangers of every vehicle you service

I can’t emphasize this enough – especially to young technicians: When you use a floor jack, also use a jack stand. When you set a twin-post rack with “flip-style” arms, face them away from each other (Figure 5). If they are screw-adjustable, make certain that the vehicle is level, and that you shake it vigorously after lifting it off the ground six inches. In addition (and I really messed up a hood in my youth), always watch the clearance between an open hood and the ceiling or hanging pipes while raising the vehicle (whoops again).

Use gloves

I recommend using latex or nitrile gloves – the choice is dictated by allergies to latex or personal preference – and it is a wise habit to adopt. This keeps used oil, grease and chemicals off your skin (Figure 6), and you can “peel-n-go” when you need to go on a test drive. They also contain any bleeding when you cut yourself through the glove!

Protect your eyes

When we undergo our National Automotive Technicians Education Foundation (NATEF) certification, students must be wearing their safety glasses (Figure 7) at all times during the evaluation. We enforce this rule on a daily basis without compromise. I am aware that many shops do not adopt this policy. Use a full face shield with your grinder and your press. How many of us know someone who has either damaged an eye or at least had to go to the emergency room to extract a chunk of metal from their cornea? Ever sprayed brake cleaner, or penetrating oil or carburetor cleaner into your eye (or am I the only one who has done that)?

Always consider an off-the-wall answer

I still keep an eye out for anything unusual, and I am consistently indulged with interesting causes for vehicle symptoms. Whether it is an aftermarket alarm system causing an intermittent no-start, or evidence of chewing or nesting creatures under the hood contributing to “breaks” in wires (Figure 8), I keep my eyes peeled for “what’s wrong with this picture.”

I hope these tips prove useful, and I am curious about how many of you knew these already, or if you picked up one or two “take-aways.” Also, if you have any great tips of your own that you’d like to share, I’d love to hear them. Maybe I will include them in a future article. You can e-mail your tip(s) to me at [email protected].

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation (NATEF) board of trustees. You can reach him at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.asashop.org or call 800-272-7467.