Tech to Tech

- Author: Jeff Bach

- Subject Matter: Diagnostics

- Vehicle Application: 2007 Ford F-150 pickup

- Issue: Short in brake-light circuit

An intermittent failure gets an old-school solution

I think one of the most-dreaded jobs a technician can get is an intermittent short. A wire somewhere that is touching a sharp edge or rubbed through to a brace or bracket somewhere just under the right conditions momentarily pops the fuse then goes back to working normally.

These have a tendency to never act up when in for repair; yet, they will invariably blow the fuse before the customer gets the vehicle back home.

Diagnosis on Ford F-150

This week I got one of those in from a customer who was recommended to come here by another shop that had given up on finding the problem. After several attempts and customer drop-offs, the shop couldn’t get the problem to occur. The vehicle was a 2007 Ford F-150 pickup, and the problem was it would occasionally blow the brake-lamp fuse. The circuit seemed simple enough, not like a spider-plant circuit we sometimes run into.

To deal with this type of problem, there are many different techniques available. I like talking with technicians when I can to see which technique works for them. The one I have settled on is an old-school technique that has been working well for me for a long time. The commercially available tools that one can choose from vary between a simple breaker and compass to the electronically controlled version of what I call the “Fox and the Hound” system.

The simple breaker and compass is used generally on a dead short by placing the breaker in place of the blown fuse and following the magnetic field through the body each time the breaker resets and sends current to the short. This method is slow, and often the large current pulse causes the short to burn away or become “unshorted.” To avoid the time-consuming task of having to drive the vehicle during the workday and racking up large labor charges of possibly fruitless diagnostic time, I recommend having the customer drop off the vehicle for me to use as a driver with my equipment connected to it, in hopes that it will act up on me while I’m driving and I can pull over and clock in on it.

This was the case on this vehicle I had been driving without incident when I was on the way back from watching my granddaughter’s recital and I spied a dead skunk on the side of the road with an unusually large amount of white striping going down its back. There was some discussion about whether this was normal or not, which led me to decide to go back and have a better look.

I found a wide drive on the right side of the road and did a sort of U-turn. I was at the apex of the turn when my short detector started flashing the lights. I pulled over and we had ourselves a long gander at the unusually colored skunk (Figure 1).

Getting to the root of problem

I went home without further incident. The next day, I took the truck to a parking lot and tried duplicating the turn. Each time I turned hard to the left with some G force, the short would occur but quit as soon as the force lessened. This was progress. Being able to duplicate the short is half the battle.

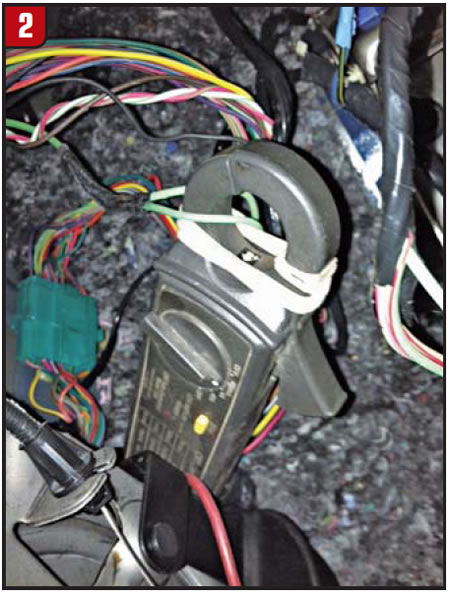

I took the truck back to the shop and tried raising the vehicle from just the left side while inspecting and thumping various suspect areas to no avail. Since I couldn’t effectively move the compass around the cab and chassis while my assistant drove the truck in the high G-force circle without (me) throwing up, I ended up connecting a current probe and scope to the circuit past the brake-light switch at the splice to see which direction the current went during the short (Figure 2).

To use the scope for this type of short-circuit testing, I hook the current probe to it and set it first to free-run while I step on the brake and see how much current is normally going through the circuit without the short occurring.

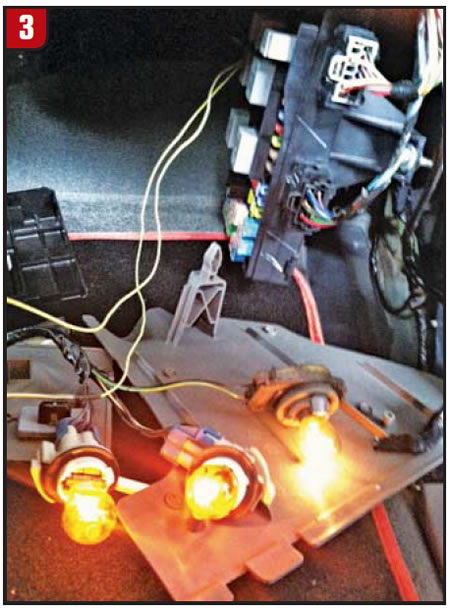

Figure 3 shows my simple, homemade short detector consisting of a three-lamp turn-signal flasher and three turn-signal bulbs wired in series to a fuse adapter. I plug it in place of the fuse that blows, and during normal operation of the circuit the lights are dim and carry enough current for the circuit to operate.

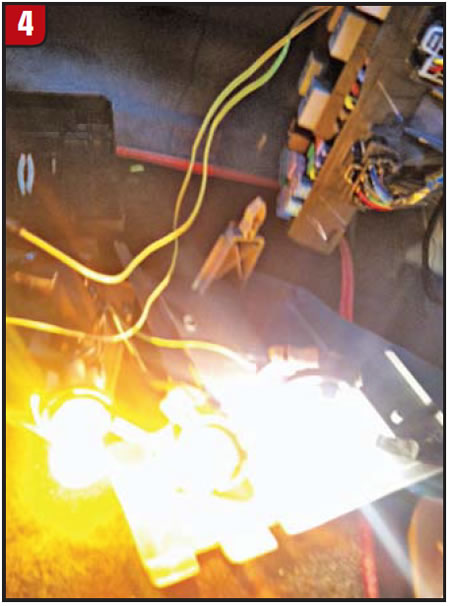

While the short is occurring, the down leg of the circuit shorts to provide a ground and the turn-signal lights get bright and start flashing without damaging the circuit (Figure 4).

This lets me see that the short is occurring and limits the current that can flow in the circuit. Next, I adjust the trigger level above the normal brake, apply current and change the scope’s trigger setting to “wait for trigger.” This way I get a pattern on the scope only while the short is occurring.

Next, I drive the vehicle again “in the pattern” and see whether the short occurs on the side of the splice that goes to the brake lights. I didn’t get a trigger, and I could see my short detector flashing while I was driving in the circle pattern. I switched to the leg of the splice that went to the front of the cab and out into the engine harness to feed a brake on/off (BOO) signal (Ford’s brake input to the ECM) to the right front of the cab where the PCM was mounted. The trigger didn’t occur while the lights were flashing. I moved the probe to the other (final) leg of the splice and drove the truck again.

This time it triggered the scope while the lights were flashing. I knew from the way the pattern went straight up off the screen that this circuit was carrying the short current.

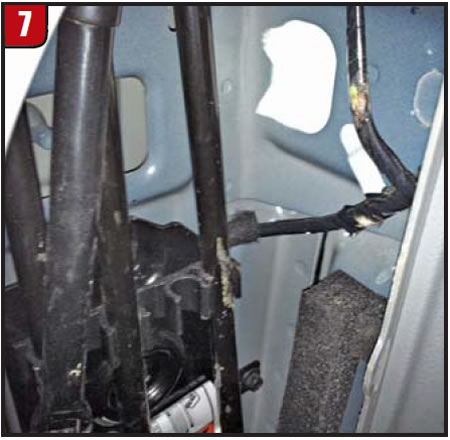

Using the current probe, I followed the wire through the harness; behind the parking brake; down the rocker; up the left-rear cab corner, where I found the body control hidden across the back of the cab; to the right-rear corner, where the tire jack was mounted and not quite bolted down securely (figures 5 and 6).

It turned out to be the wire going up to the high-mount stoplight on the top of the cab (Figure 7). Once I found the location of the short, I could easily duplicate it by pushing gently on the jack (now removed to expose the short). This was one of those hard-to-find problems that took some time and effort to trace. I found out later that I was not the first person to have tried to tackle this problem. The glove box had a bounty of blown 20-amp fuses.

I thought it was ironic that my curiosity about the skunk turned out to be the thing that kept me from getting skunked.

Jeff Bach is the owner of CRT Auto Electronics in Batavia, Ohio. You can reach him at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.