BorgWarner Powertrain Distribution Center

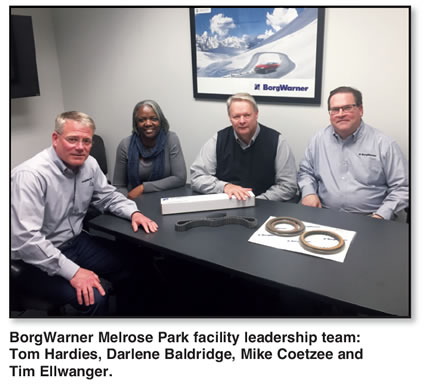

Transmission Digest recently visited the BorgWarner Powertrain Distribution Center in Melrose Park, Ill. A lot has changed since the last visit in 2015 including the new location. The new distribution center is near major transportation hubs including airports and interstates making it cost effective and convenient to bring in BorgWarner products from around the world. The Powertrain Distribution Center manages a supply of components from more than 10 BorgWarner facilities around the world and ships product to more than 100 customers in 17 countries.

Mike Coetzee, Vice President and General Manager of BorgWarner’s North American Transmission Systems Group advised a lot went into the selection of the new facility including the retention of the team and the infrastructure necessary to expand beyond traditional automatic transmission parts. “The next several years will be exciting as we continue to add additional BorgWarner powertrain products to our portfolio,” he says. “Access to BorgWarner’s powertrain product line has improved with the recent addition of our Hy-Vo® Chain from the Morse Systems Division and our plan to offer the AWD Coupling products from the Power Drive Systems Division later this year. As global demand continues to grow, BorgWarner is now engaged with our teams in both Europe and Asia to offer customers in those regions competitive products with shorter lead times.”

Operational excellence

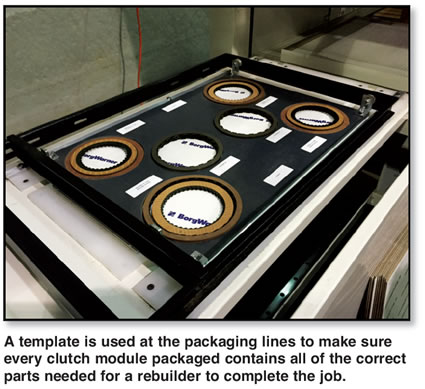

BorgWarner is a technology leader producing powertrain parts for almost every original equipment manufacturer in the world. Supplying these customers’ products at the required levels of quality requires facilities to be extremely clean, organized and efficient. The Melrose Park Distribution Center is no exception, says Darlene Baldridge, Operations and Business Manager of the facility.

Baldridge says, “Since moving into our new location, the warehouse supervisor and team members have focused their efforts on implementing BorgWarner’s’ standard of excellence for a safe working environment. These efforts include incorporating ergonomic lift equipment in our redesigned production areas, replacing our fleet of mobile equipment and implementing 5S work standards throughout the facility. These improvements have greatly increased operational efficiencies and throughput to support new product lines and future growth opportunities.

“Improvements made in our SAP operating systems and the continued education and training of our team members ensures customer orders are received, processed and shipped to meet or exceed lead-time commitments. In addition, recognizing the volatility of market demand, we’ve enhanced our planning tools to increase forecast visibility to our global manufacturing plants. This process improvement will allow the plants to better react to the market demand changes and support our inventory initiatives.

“Of course, customer satisfaction remains the focal point of our business. Maintaining good rapport with long standing customers and developing those same relationships with new customers through growth opportunities is very important to us. We pride ourselves on sustaining an overall order fill rate of 95% or higher. This is mainly accomplished through open communications with our customers and the collaborative work efforts of the Melrose Park team.”

New product lines

New products for the company’s core transmission product lines, including friction plates, one-way clutches, bands and solenoids are routinely introduced. The Melrose Park team says it continuously works closely with other BorgWarner divisions to offer customers one point of contact for many other BorgWarner Powertrain products. The most recent additions to the products handled by the facility are Hy-Vo® chain drives. AWD coupling product and additional transfer case products will be available later in 2018.

Tom Hardies is sales manager / business development for the operation. He observed, “These are exciting times as we work with customers and other BorgWarner divisions to offer products that historically have been difficult to get due to very long lead times or have been too costly after going through multiple distributors. All current transmission part customers can now order BorgWarner transmission and transfer case Hy-Vo® chain and have it included with their order. As Mike said, later this year we will be adding the AWD couplings and additional transfer case products.

“Those AWD coupling parts coming later this year will include oil, filters and pumps for BorgWarner Gen IV and Gen V AWD couplings. Although most demand for these is currently in Europe, demand continues to increase in North America. The oil and filters are typically serviced at 50,000-mile intervals. Pumps, depending on how aggressively driven, are typically replaced at 150,000 miles.

Performance transmission products

The company’s engineers observe that friction technology developed for new eight-, nine- and 10-speed transmissions have performance requirements that far exceed historical three-, four-, five- and six-speeds. BorgWarner’s engineering and business development team continues benchmarking current “performance” friction materials against the new generation of BorgWarner friction materials. The results are very promising and may be game changing for the current performance market. With a lot of bench and lab testing now complete, the next step will be field testing.

Sales Manager / Business Development, Tim Ellwanger and Performance Product Engineer Chris Horbach say they understand the test data for these new friction materials will further demonstrate BorgWarner’s product leadership position. During Phase One, BorgWarner will be partnering with a select group of customers to provide new performance friction technology for targeted uses such as diesel truck applications.

“Our market feedback has provided insight into what the performance market is looking for from BorgWarner,” says Ellwanger.

Adds Horbach: “BorgWarner will utilize standard SAE MuPVT testing across 16 different conditions with varied pressures, velocities and temperatures to demonstrate friction coefficients across a range of conditions. In addition, our SAE step level durability testing will stress a clutch pack to failure by increasing shift energies for a specific number of cycles to demonstrate overall friction material durability. In order to meet or exceed our customer’s requirements, our customers want three specific attributes in our products: performance (MuPVT+Step Level), reliability and quality. BorgWarner is currently planning several new performance product introductions for the Powertrain Expo in November 2018.

Hardies concluded, “The BorgWarner Powertrain Distribution Center team looks forward to the next Transmission Digest visit. If past trends continue that will be in 2021, three years from now. By that time the expansion to offer all of BorgWarner’s Powertrain’s product lines should be complete. And by 2021 the aftermarket four- and five-speeds will have declined sharply and the six- and eight-speed products should be making up the majority of product being sold. Nine- and 10-speed products will be entering the market and those will include new technologies offering significant weight savings and reduced parasitic drag for improved fuel economy. New vehicles entering the market will have significantly more electrification too. That electrification technology is something that BorgWarner is actively developing at the current time. These new products will then be entering the market to replace 10-speed products. It is exciting to see all the opportunities and technologies the future holds. It is great to be part of a company that invests so much in the future and its people.

Highly Engineered Components

The BorgWarner Powertrain Distribution Center and its team of people are one part of a much larger global corporation. BorgWarner Inc. is, according to the company, a product leader in highly engineered components and systems for powertrains around the world. Operating manufacturing and technical facilities at 74 locations in 19 countries, the company delivers innovative powertrain solutions to improve fuel economy, reduce emissions and enhance performance.