Up to Standards

- Subject: Operating principles, diagnosis and repair

- Unit: BorgWarner 4473 transfer case

- Vehicle Applications: Chevrolet Express, GMC Savanna vans

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

General Motors’ Chevrolet Express van and GMC Savanna van are full-sized vans that come in three versions – 1500, 2500 and 3500 – reflecting gross vehicle weight of 1/2, 3/4 and 1 ton. The design is efficient and very nicely tailored for fleet and commercial use and for a large-capacity people mover. These vehicles are all-wheel drive, which means that the driver has no input.

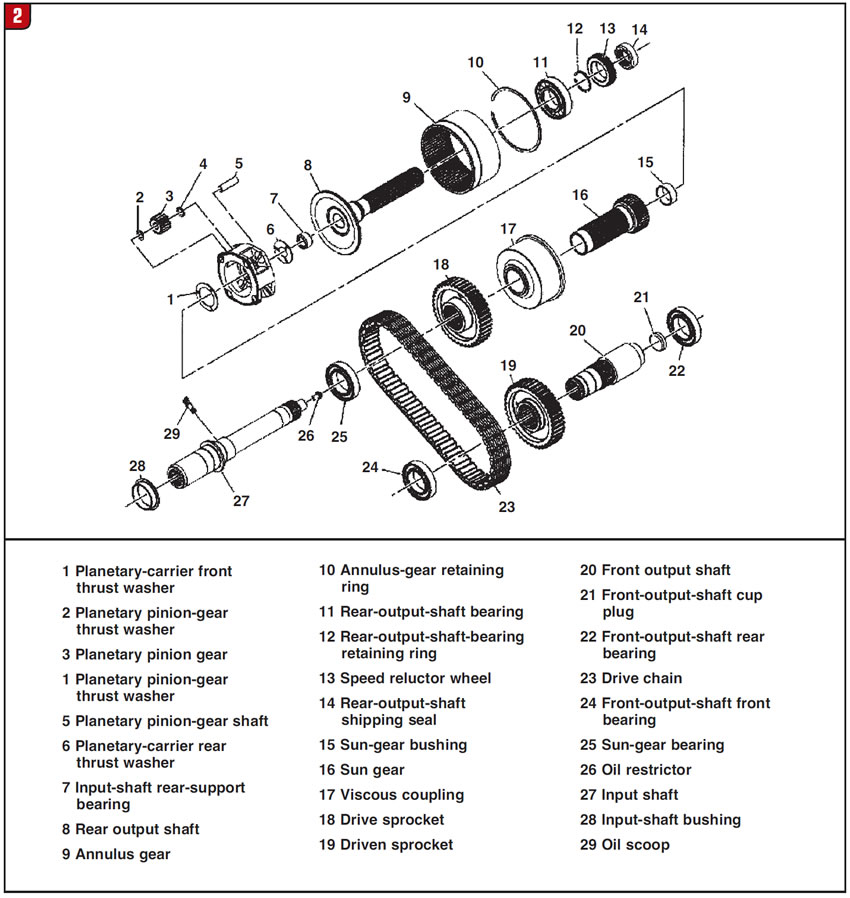

Through the BorgWarner 4473 transfer case, which is full-time all-wheel drive, there is a 35%/65% constant torque split front to rear. The 4473 is a relatively simple transfer case that uses a viscous coupling to control a planetary differential to split the torque. The planetary uses straight-cut gears for the planet pinions and the sun and annulus gears, which means that there is little or no thrust load on the internal components.

The usual issues are present with any vehicle having a viscous coupling, the principal concerning tire size and pressures. The viscous coupling is highly sensitive to mismatched tire sizes and pressures. I have discussed the operation of viscous couplings in previous articles, but we will make a quick review.

The power is transmitted through the viscous coupling, which is a sealed unit containing alternately splined steel discs similar to those in the common clutch pack. These discs, however, are not lined and never touch each other. About one-third of the coupling is filled with a silicone fluid that expands quickly when heated. When the front prop shaft is not rotating at the same speed as the rear shaft, the discs turn, causing the fluid to expand and fill the case of the viscous coupling, and as the discs begin to sheer through the heavy fluid, they now send power to the axle needing it. When prop-shaft speeds equalize, the discs stop turning and the fluid shrinks in the case.

The rolling radius of the tires is critical to the operation of the viscous coupling and its life span. If you do not measure each tire individually with a stagger gauge to make sure they are within 1/4 inch and all tire pressures are identical, you are committing financial suicide. The viscous interprets the difference in rolling radius due to mismatched tire size or pressure as wheel slip and will kill itself in short order trying to equalize the difference. What generally happens in these situations is that the viscous overheats and in doing so ruins the seals on the shafts that are contained inside. As the seals weaken, the lube fill enters the viscous, and since it is overfull it locks up. In other instances, the fluid will leak out of the case of the coupling and the coupling will no longer transfer torque, and all-wheel drive is lost.

Some dos and don’ts with viscous units:

Do not run these units with all four wheels in the air. This will over-speed the planetary differential and cause it to fail. Do not drive the unit on a two-wheel-drive dyno for dynamic emissions testing. Unless all four wheels are turning at road speed the planet will overheat.

It is possible to test the viscous coupling on a lift. The factory test is to install tool J45382 (socket) onto the front output shaft of the transfer case. Put the transmission in neutral and set the parking brake to the rear wheels. Using a pound-inch torque wrench set at 100 lb./in., turn the front output shaft 90° while timing how long it takes to move 1/4 revolution. If the viscous turns easier than 100 lb./in. or takes less than 10 seconds to go 1/4 turn, it is done. If it takes more than 100 lb./in. to turn or longer than 10 seconds to make the 1/4 turn, the coupling is probably locked up and needs to be replaced. A result of 100 lb./in. and 10 seconds indicates a good coupling. Obviously this test is only an approximation, and a little bit off one way or the other is as exact as you can get. Do not operate the unit without both driveshafts in place, as this will damage the viscous and the planetary differential.

These are very simple units, and it is strange to see how much damage they come in with. One of the problems you face in repairing the 4473 is that parts are captive to the dealer and BorgWarner cannot sell them into the aftermarket. This makes it usually cheaper to buy a reman than to buy all the parts required for a proper rebuild.

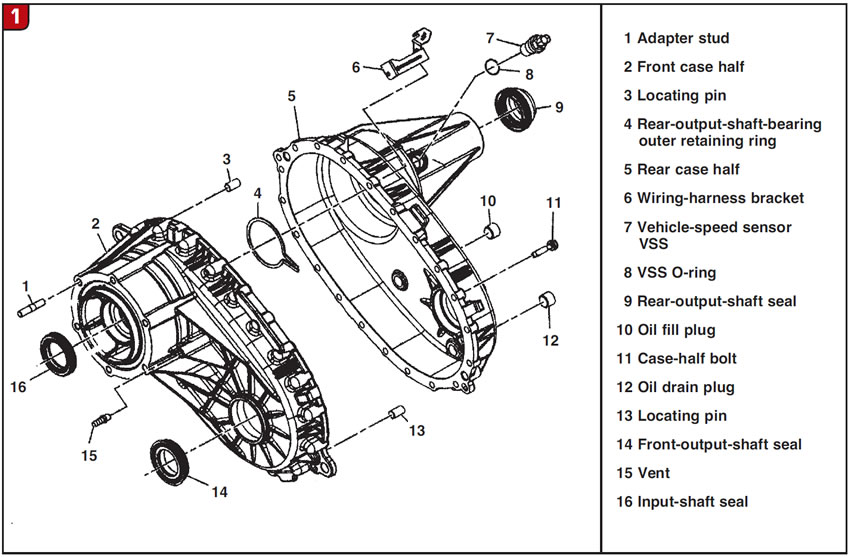

We have a lot of experience with these units and have done a lot of research to understand the causes of failures. The most-common failure is the rear-case output-shaft bushing. The rear case has a bronze bushing molded into it and then machined to size for the rear-driveshaft yoke. This bushing is not replaceable, and failure means replacing the rear case half. Be careful to check the rear driveshafts for balance and straightness, as the commercially used vehicles tend to get driven over obstacle courses. When you replace the rear case, the new one you will get will have a babbitt bushing that is replaceable. Another common failure is that the rear output shaft that is splined to the annulus gear will lose the rear output bearing. Figures 1 and 2 illustrate all these failures. The front case also suffers from the input shaft spinning out the front-case bushing that supports it. The bushing can be replaced, but many times it spins in the case and the case is unsalvageable. This also means that the input shaft may wind up with the front bushing seized to it, requiring replacement also. At the same time you will find many stretched or overheated chains and, of course, the poor old viscous coupling. This is now getting very pricey.

When doing root-cause failure analysis, you need to go through the theory of operations and check how these failures occur step by step. We have a simple straight-cut planetary differential, sun gear and annulus gear. With helical-cut gears one would expect high thrust loads on the components, which could cause the type of damage common in these units, usually caused by overloading or extreme-duty driving. With these straight-cut gears there is no thrust load, so why these problems?

The next step took a lot of research and trial and error, but looking at the operation system helped. The chain is always turning whenever the vehicle is in motion.

The lube fill in this unit is ATF, and the factory fill is 1.4 liters or 47.3 ounces (about 11/2 quarts). Lubrication in these units is by splash with no pressurized pump feed. It had to be lack of lube. How can this be? You fill the unit to the fill-plug level and it should be fine, but this is not the case. The unit needs more oil to live. After you fill one to the fill-plug level and replace the fill plug, you need to remove the speed sensor from the rear case and add one more liter of fluid (1.06 quarts) and replace the speed sensor. GM now has a service bulletin out on this, # 08-04-21-004 issued April 16, 2008. It took only a few years for them to catch up. GM specifies the use of Dexron VI fluid, part number 88861003, but for more security we suggest using 5W30 motor oil, for better film strength and less misting.

Another area on the Express and Savanna vans that needs some attention is the rear ends. The 1500-series vans with six-lug wheels use an 8.6-inch rear; the 2500 and 3500 models use a special Dana Super 60 rear end. This Super 60 is all by itself with a unique ring and pinion. All units use a 7.25-inch independent-suspension front-axle assembly. This is a very small differential for the type of loads that these vehicles take and should be looked at carefully every time you work on one.

Mismatched tire sizes, besides killing the viscous coupling, will overheat the front differential in many instances. Remember, if the tires are mismatched on the front or rear axle, the differential side gears are working all the time as if they were in a turn. When the tire sizes are correct, the side gears will travel at the same speeds with no differentiation.