Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: 2004 Subaru Forester

- Issue: Consistent chatter

Mike Riley investigates a 2004 Sbaru Forrester that jerked while accelerating on a right turn.

Complaint/Concern:

The owner of a Subaru started to experience something with his vehicle that he felt was unusual but really could not discern what it was initially. As time went on, though, the sensation became more pronounced, and he finally realized that under certain conditions the vehicle would jerk while accelerating on a tight turn. What the vehicle owner did not know was that his problem was as common to Subarus as the flu.

By the time that the owner brought the vehicle to the shop, the chatter while on a turn was pretty consistent, especially when hot. The Subaru was a 2004 Forester AWD equipped with a 2.5L non-turbo engine and four-speed automatic transmission. The vehicle had 97,000 miles on it and was in great condition. The engine ran well and the transmission functioned fairly well considering the mileage, except of course for the chatter. It didn’t appear that anything was ever done to the transmission.

Cause/Condition:

As with previous model AWD Subaru vehicles equipped with a four-speed automatic transmission, there were several possible causes of turning chatter affecting the Forester that had to be ruled out. Since nothing was ever done to the transmission it was decided to start with a fluid change to see if that would have any effect with the chatter. The pan was dropped along with the filter to look for any wear and tear as well as to check the condition of the fluid. The pan and filter were pretty clean and although the fluid did have a slight odor and discoloration was not in too bad of shape.

Due to the mileage the fluid and filter were changed and the vehicle was taken for a road check. Initially, the unit worked well; however, as the vehicle warmed up the chatter returned, to no one’s surprise even though the used-up fluid can certainly cause the problem.

With step one completed unsuccessfully, step two meant yanking off the extension housing to examine all of the transfer-clutch stuff. Before the transfer clutches were removed from the drum, the assembly was air checked to ensure that the apply piston was not leaking. The piston seemed to apply normally, without a hint of leakage, and the frictions and steels locked together accordingly. The clutch plates were then removed from the drum and inspected to look for any sign of slippage or chatter. Overall, the frictions seemed to be in pretty good shape and the steels were heat-treated with no sign of damage.

The next item on the list had to do with the controls. Even before the fluid was changed a scanner was connected to the vehicle to look for any computer-related signal issues, and everything appeared to be firing normally. Since there has also been solenoid-related issues concerning chatter, the transfer clutch solenoid was removed and tested to make sure that it was operating correctly, which it seemed to be.

The remaining item on the list of things to do was to inspect the transfer clutch solenoid body to look for a sticking or worn valve or bore. During the removal process, though, the builder noticed something else that could have contributed to the problem that had nothing to do with bad clutches, solenoids or bodies. The oil distribution tube was so loose that it could almost fall out on its own.

Correction/Modification:

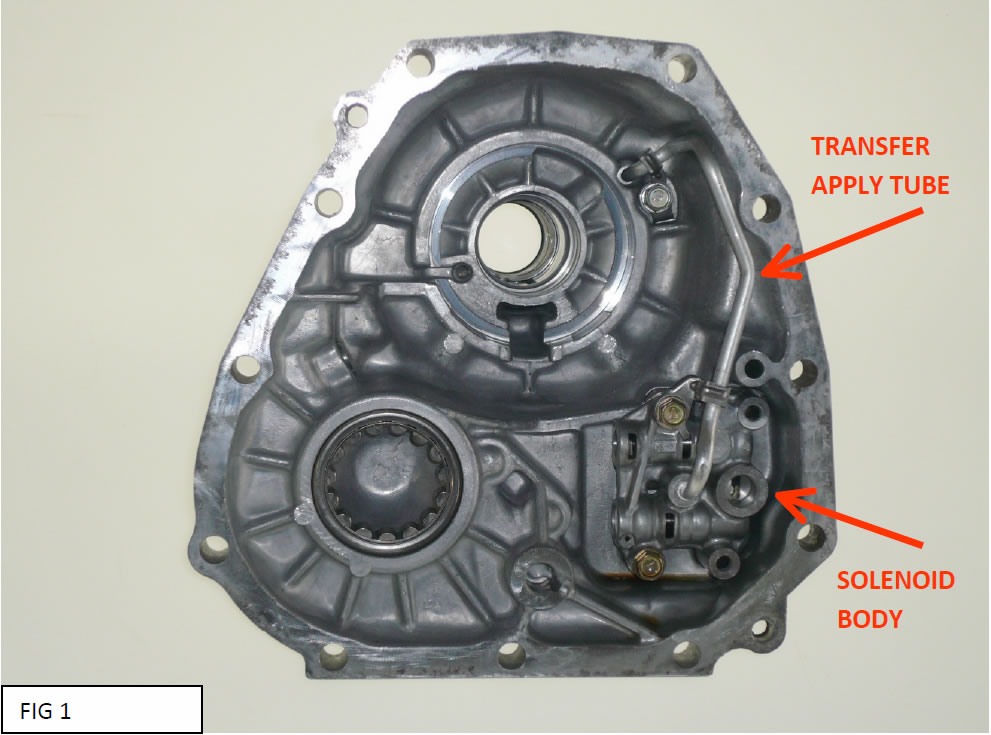

The transfer clutch in a Subaru four-speed automatic transmission can be fed a couple of different ways depending on transmission design. The first-design four-speed unit launched in 1987, was the R4AX-EL which had a transfer clutch solenoid and valve body bolted to the extension housing (Figure 1). The tube distributes apply oil directly from the solenoid body to the extension housing sealing ring bore and is held in place by a couple of clips. The tube is aluminum and can fatigue and loosen after a period of time and create a leak in the circuit.

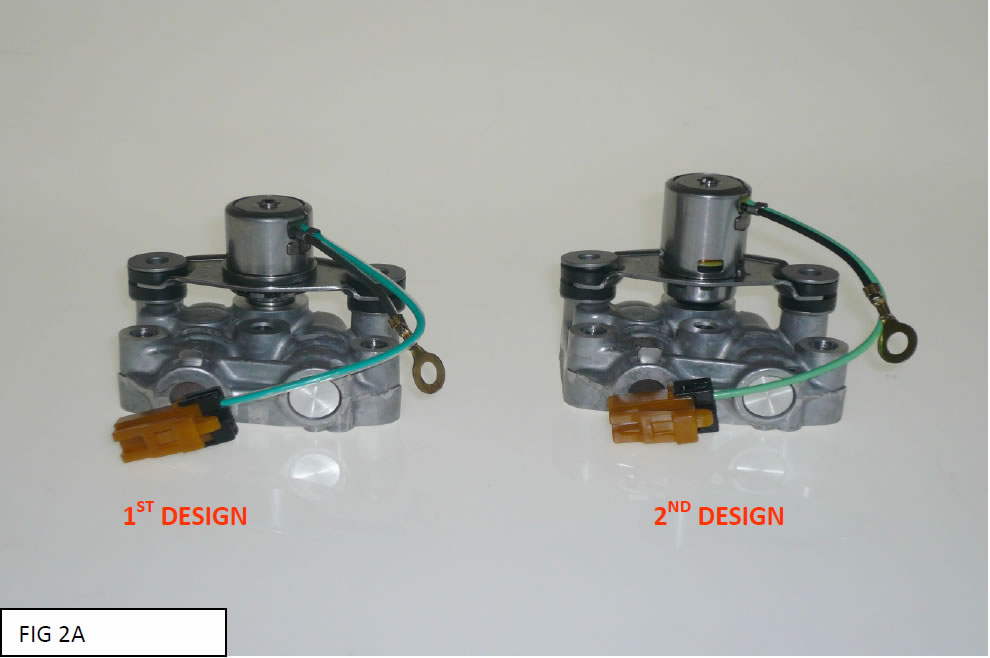

Although there has not been massive changes to Subaru four-speed transmissions, for some reason the transfer clutch system has been modified just a tad. The first design solenoid body, which is somewhat rectangular, contains two valves and was basically unchanged over the years. That cannot be said for the solenoid itself (Figure 2A). For some reason Subaru decided to modify the solenoid slightly in mid-’95 creating a second part number. Both the first and second design valve bodies contain the transfer-clutch oil-apply hole for the tube, (Figure 2B). When purchasing the solenoid, the body is provided free of charge. The first design part number is 31942-AA061 and the second design number is 31942-AA090.

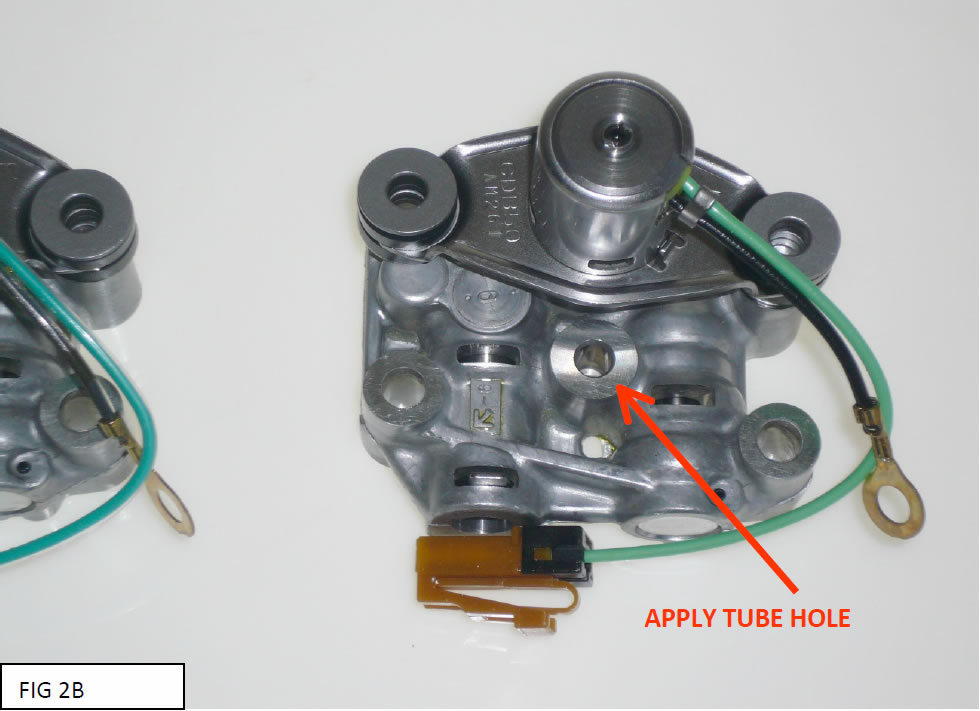

Subaru launched its second-design four-speed transmission in late 1998, which is referred to as phase II, with several notable component differences from the first design transmission, including the transfer clutch stuff. The first item of note is that the solenoid body was moved from the extension housing to the back of the case (Figure 3).

Regardless as to the reason why is the fact that there is still an aluminum distribution tube to contend with, which is what caused the chatter issue on the Forester. In addition to the tube, there is also a flat compression seal that goes between the extension housing and transfer solenoid body that must also be replaced.

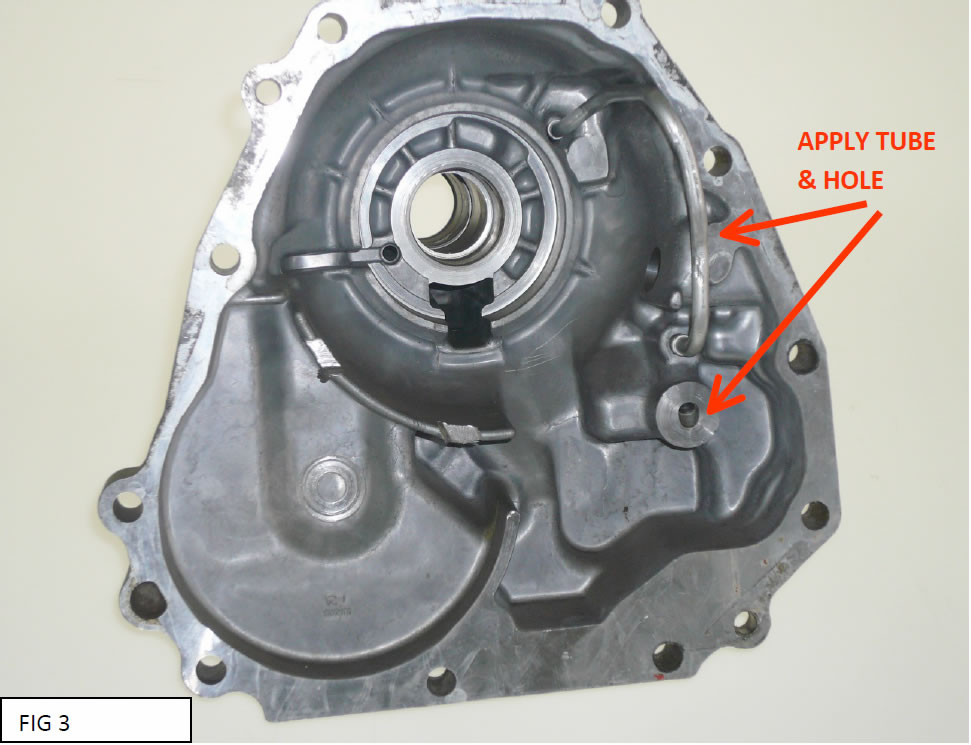

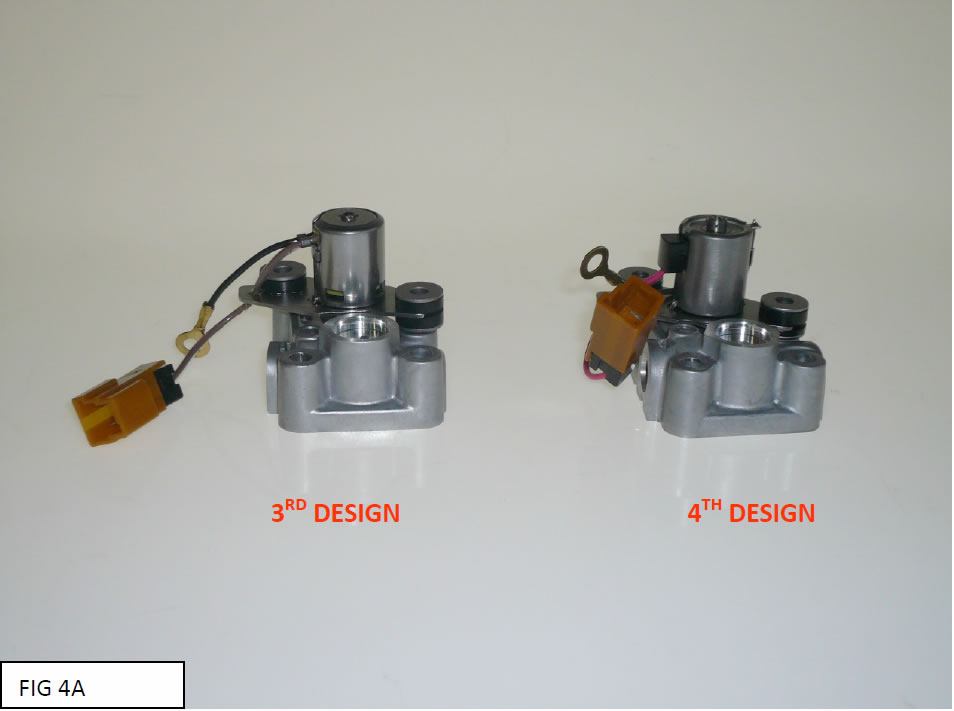

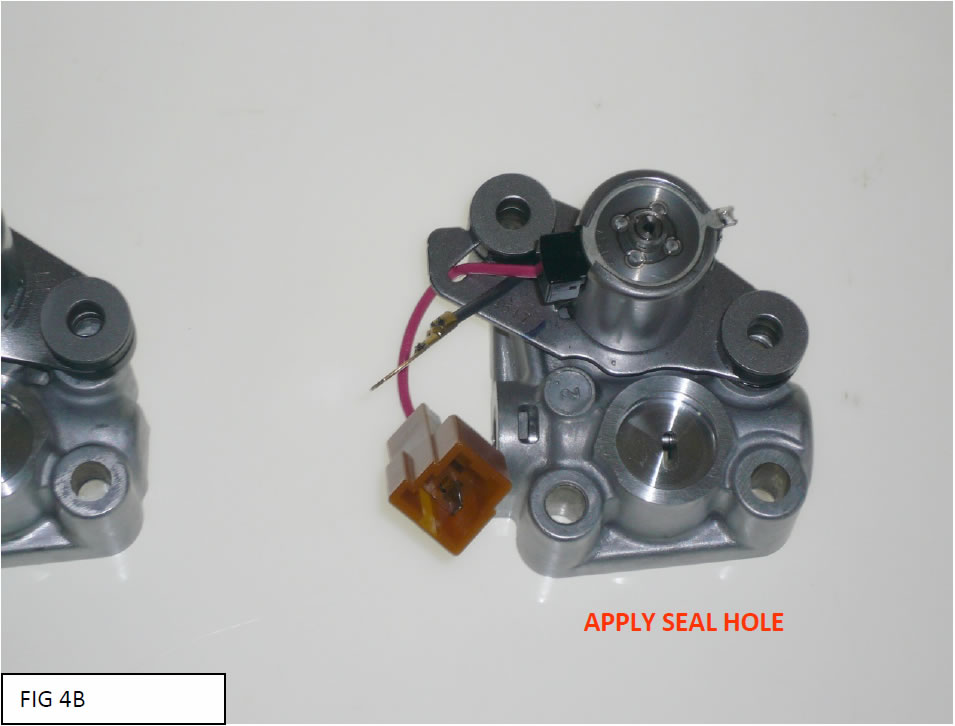

When the new-design transmission was released, a new-design transfer clutch solenoid and body was also developed. Unfortunately, just like the previous design transmission, Subaru decided to make another change to the transfer clutch solenoid and body in mid-’03 (Figure 4A). Unlike the previous scenario, though, the oil passages are different between the third and fourth design bodies as well as the solenoids themselves. Both design bodies are somewhat triangular and only contain one valve, unlike the earlier models. The solenoid body contains the pocket for the compression seal that goes between the extension housing (Figure 4B). As with previous design solenoids, the third- and fourth-design solenoids and valve bodies are only available as a complete assembly.

The third-design part number is 31942-AA103 and the fourth-design assembly is part number 31942-AA130.

Lastly, in 2004 and depending on vehicle model, Subaru gave the four-speed another facelift involving not only the transfer clutch system but also the main valve body as well. The new phase II version II model transmission now has the transfer clutch solenoid as part of the main valve body and currently is not available separately. Fortunately, Rostra has addressed this issue by releasing a modified solenoid assembly to avoid replacing the entire main valve body (Figure 5). In effect, Rostra uses a solenoid from a VW AG4 along with a special fixture to adapt to the Subaru valve body. Hopefully, Subaru is done with the changes. The 2004 Forester, for instance, could have either transmission design based upon having a turbo or non-turbo engine.

In the end, the chatter issue was fixed by merely making the oil distribution tube fit tightly and applying an epoxy sealant, not by changing a lot of parts.