As technicians, we are often faced with build issues that can sometimes be frustrating at first. But with a little ingenuity, these frustrations can be turned around and made simple.

In 1989, Dodge came out with the first fully hydraulic electronic-solenoid shifting transmission, the A604 (no shift valves), which later became the 41TE. Originally, there were several issues that had to be worked through, but we now have entered an age in which most late-model transmissions are shifted through electronics.

Still, there are two different methods of controlling the shift, which are:

- Solenoids that control clutch feed oil being directed through the solenoid passageways seating switches — whether that takes the form of controlled switching from a checkball, or in the case of this discussion, separation of switch plugs.

- Solenoids that direct oil to a shifting “switch” valve (such as a valve or plug named 1-2 or 2-3 etc.) that directs the oil to the clutch it controls.

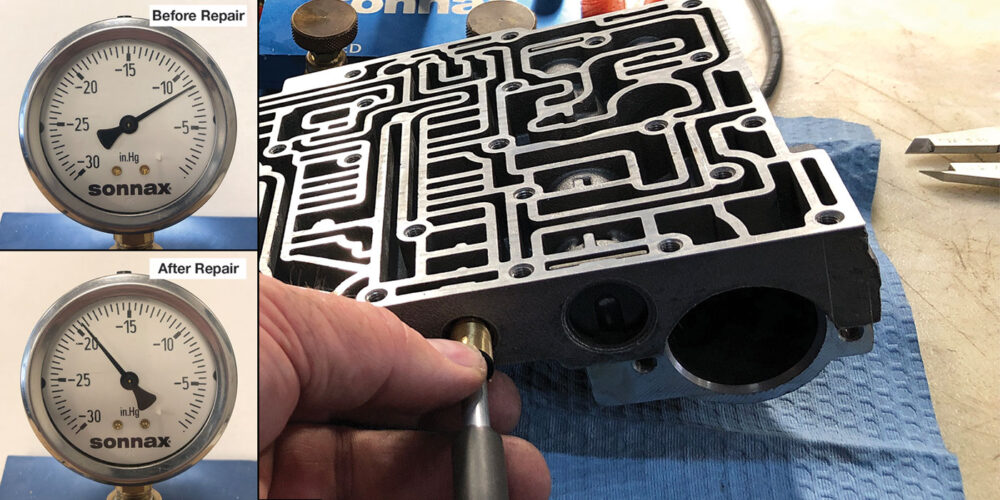

In this family of Dodge transmissions, switch plugs leaking can lead to issues ranging from pressure switch rationality codes—which are monitored through electronics—to burnt clutch assemblies that are being partially applied and smoking the clutches. Testing the bore fit of these plugs can sometimes be frustrating and often result in false answers when using conventional vacuum test procedures with a test plate (see Figure 1).

A good friend, fellow builder and coworker recommended that this article be titled “Don’t get stiffed by the switch.” So, let’s make this simple!

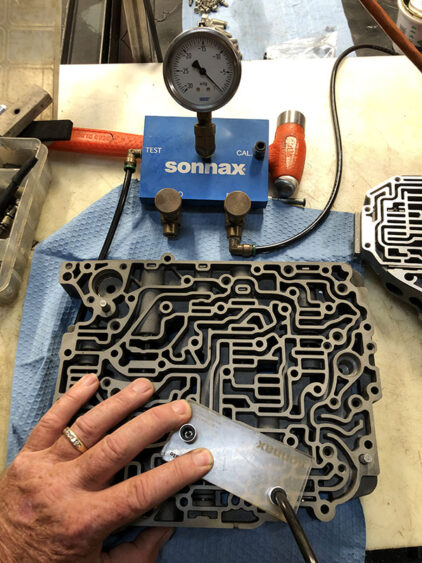

An easy, effective solution is to make your own test tools (like those in Figure 2) using an OE (standard-size) plug as well as the oversized version of the plug (a larger aftermarket part installed after bore reaming to repair wear).

Keep in mind that there are two different sizes of switch plugs used with these units: .420-in. and .453-in. You’ll need to have one of each size OE valve handy. Here is a full list of everything needed to make test tools:

- One standard .420” diameter OE switch plug.

- One standard .453” dia. OE switch plug.

- One oversized replacement switch plug being used. The one used here measures .473-in. dia. after ream.

- A 1/8-in. quick-connect test fitting.

- Measure the OE valve large spool diameter shown to verify which one you have (see Figure 3).

Here is the process:

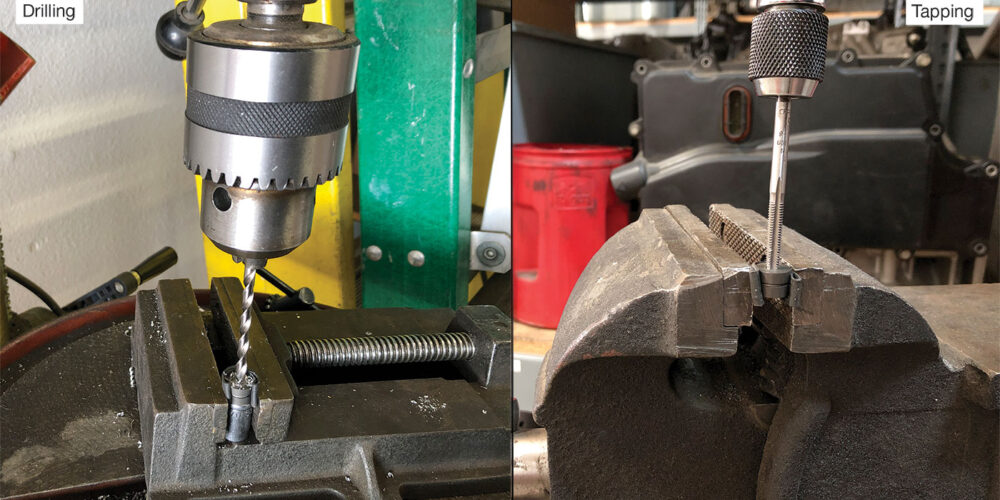

- Using an OE plug (either a used one or a new direct replacement valve), drill a hole with a #21 drill or a drill that measures around 0.174-in. down the middle of the valve.

- Tap the newly drilled hole with a 10-32 thread tap to allow the use of the quick-connect test fitting (see Figure 4).

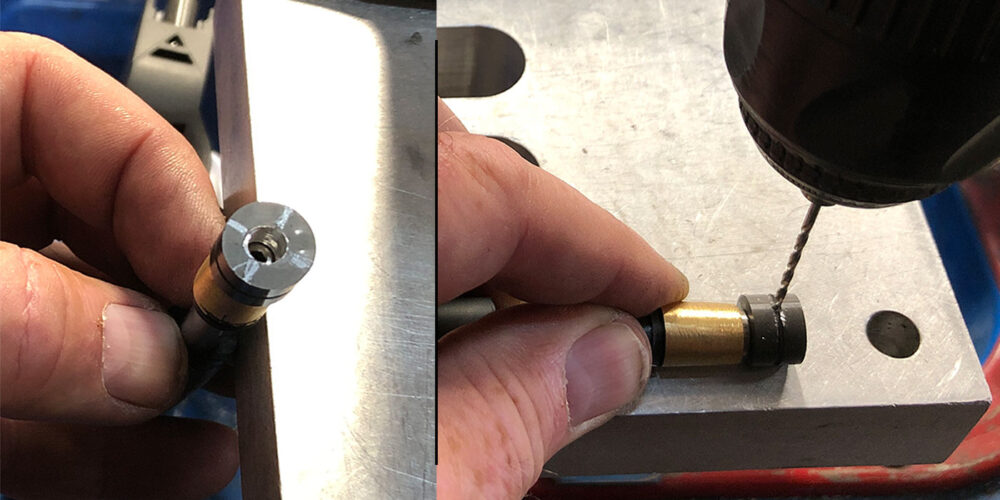

- Drill four holes in the oil grove at 12-, three-, six- and nine-o’clock positions in the valve using a 0.050-in. drill or smaller (see Figure 5). It is important to clean off the burrs from the drilling. It is not recommended to file the burrs; instead, use a simple scraping method (see Figure 6).

- Plug the open end of the center hole that was drilled and tapped by using a suitable plug or a cut end of a 10-32 screw (seal or glue the end of this tool shut). If silicone is used, be careful that it is in the open area of tool not blocking any of the four access holes. Make sure you have time to let the tool set and the silicone harden before use.

- Now, use the tool shown in Figure 7 to vacuum test the switch valve bore. It’s a simple way to get a very accurate test before and after every repair.

Thinking outside the box, you can be creative making homemade tools to ease testing as well as assembly issues. Truthfully, in my travels and teaching, I have not met any technician who doesn’t have an arsenal of homemade tools.

This article is just a simple example of making a tool that makes testing many Chrysler units a breeze. Always think, “how can I make this test easier?” Typically, you will do the rest!

Read more columns from the TASC Force Tips series here.

Randall Schroeder is a Sonnax technical support training specialist. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.