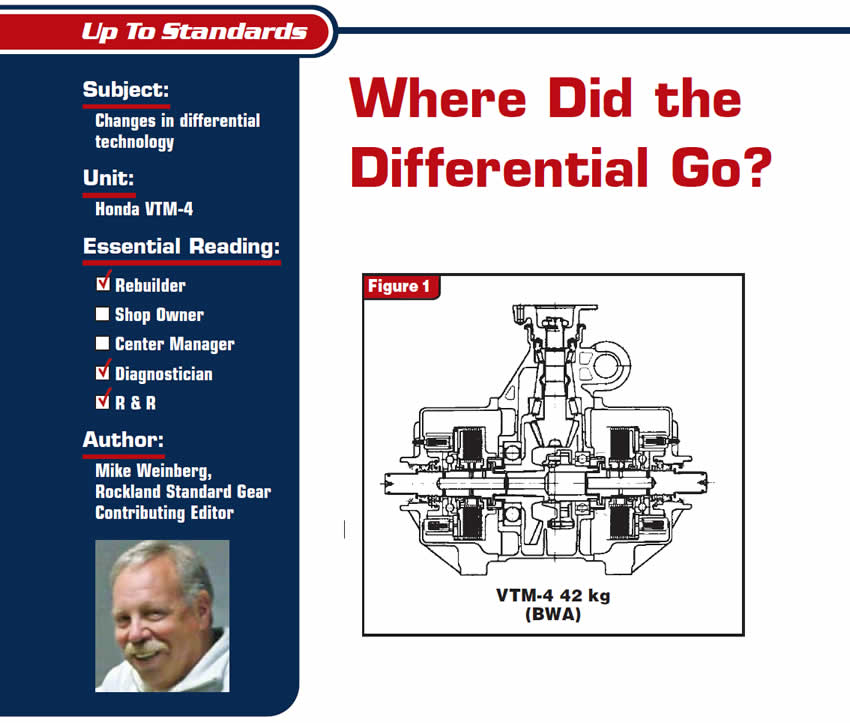

Where Did the Differential Go?

Traditionally, all motor-vehicle final-drive elements (differentials, or rear ends) have consisted of a ring and pinion, with the ring gear mounted on a differential carrier. The differential carrier contained a set of side gears splined to the drive axles and a set of pinion gears allowing the side gears to rotate at different speeds.

The differential is necessary because the outside wheel on an axle has to cover more distance in a turn than the inside wheel. This means that the outboard wheels must rotate faster than the inboard wheels; hence, the “differential” in wheel speed.

The Great Unknown

Replacing parts is the last step in the repair process. The first step should be a methodical diagnosis to isolate the cause of the malfunction. This is not possible unless you understand how the component you are working on is supposed to operate and how it is related to the other systems that make up the modern motor vehicle.

Myths and Mysteries: The Top 15 Tech Calls Involving Transfer Cases

The first consideration for anyone in the automotive-repair business must be customer satisfaction, as the best advertising is the word of mouth generated by happy customers. As a buyer of parts you also should be concerned with customer satisfaction, since you are the customer. One of the necessities of this increasingly complex business is that your vendors supply you with not only quality parts but also technical help to ensure your success in diagnosing and repairing the unit you are working on. This article covers the 15 most-frequent transfer-case inquiries that we receive on the tech line, with No. 1 being the most-commonly asked question.

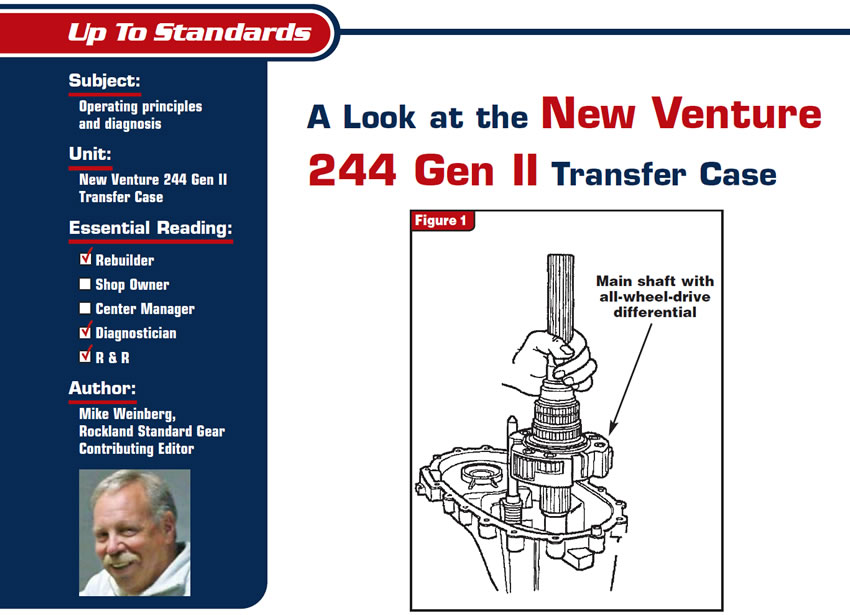

A Look at the New Venture 244 Gen II Transfer Case

We have become used to a never-ending stream of new technology and the introduction of many new models of transmissions and transfer cases. I remember the days when we had only about 20 transmissions to worry about and roughly a half dozen transfer cases; now, you need a computer to keep track of all the different units.

Worldwide Conditions and New Transmission Technology

With the technological advances of the past 100 years the world has become smaller. Fax machines, the Internet, cell phones and the globalization of industry have created a business climate that is evolving at an incredibly rapid pace.

How Things Work: Four-Wheel-Drive Systems

The transfer case is a very simple concept. It is basically a power divider mounted on a transmission that is capable of splitting torque produced by the engine to drive both sets of axles on the vehicle.

What Went Wrong and Why: Root-Cause Failure Analysis

Comebacks will have many causes, including some that are beyond the shop’s control – such as human error and new parts that are defective right out of the box. If a shop is not running at a comeback rate of 5% or less, it will be dangerously close to failing as a business. This is because there are two costs involved in repairing a comeback: The first is the parts and labor invested for free in honoring your warranty; the second loss is called “lost-opportunity costs,” which reflect the fact that when working on a comeback you cannot be working on a paying job. We will examine here how to make a comeback into a positive experience even though it costs money, and how to cut your losses and protect yourself from further wasted labor and parts dollars.

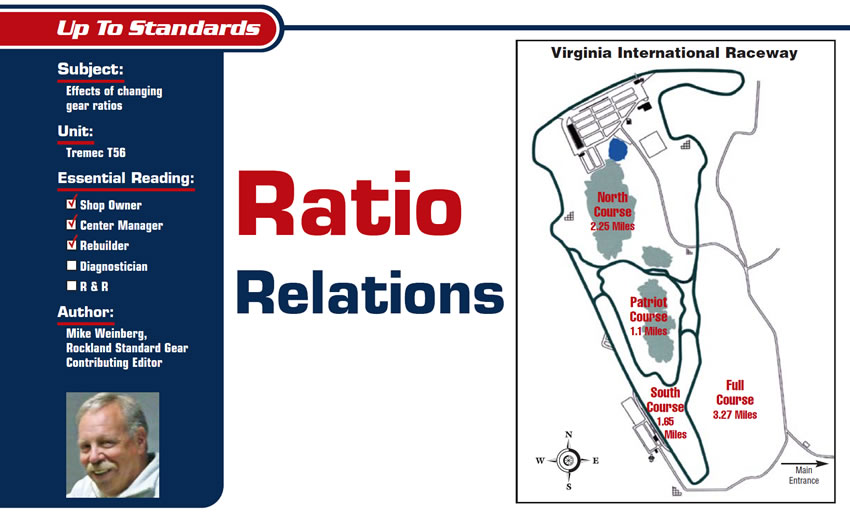

Ratio Relations

What is little understood by the public is how much work goes into developing a new race car. The platform of the stock GTO is modified to the maximum the rules allow. The car will compete at 2,800 pounds and has 260 linear feet of roll cage in it. A fuel cell, a modified LS6 engine equipped with Crane cams and producing 420 horsepower at the rear wheels, adjustable gas shocks, racing brakes, an Exedy racing clutch and a Tremec T56 six-speed transmission all work to make this car capable of 160-180 mph.

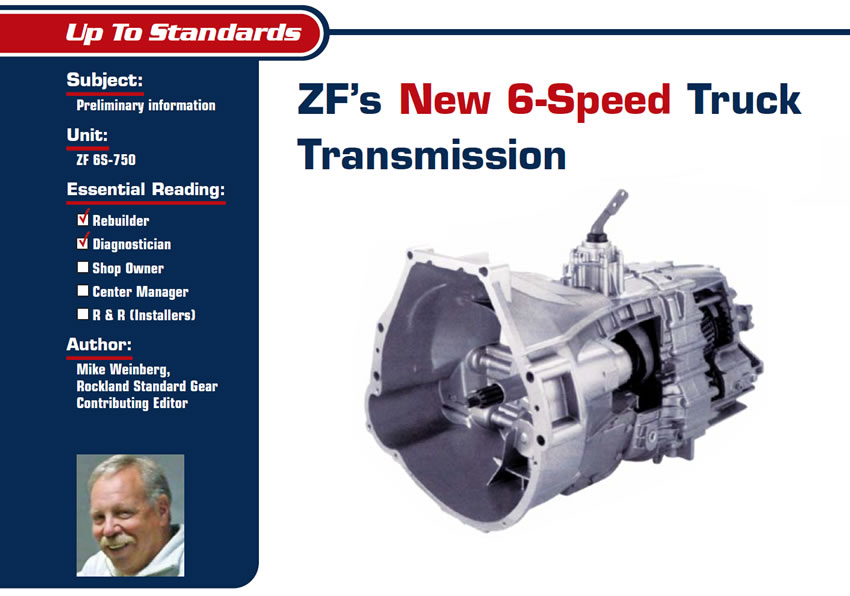

ZF’’s New 6-Speed Truck Transmission

At this point, anyone working in our industry should be familiar with ZF transmissions. ZF Friedrichshafen AG is a world-class manufacturer of driveline components to the auto manufacturers. ZF designs and builds some of the most-advanced and sophisticated manual and automatic transmissions for cars and light trucks. The company also is big in medium- and heavy-duty on- and off-road transmissions as well as steering gear, and other driveline components.

The Rear Up Front

With four-wheel-drive and all-wheel-drive vehicles being produced in such huge numbers, these trucks and cars have become an important source of repair business for our industry. Transmissions and transfer cases are now a huge part of the repair and reman market. It is also obvious that these designs use both front and rear differentials to transfer power to both sets of drive axles. This has effectively doubled the amount of differential work that will find its way to the repair shop.

Breaking the Code on Encoders

Transfer cases have become quite sophisticated, and many designs have extensive diagnostic routines. From what we see on tech-line calls and in helping customers resolve field problems, there is a great lack of information and understanding at the shop level. This article is devoted to understanding the electronic shift functions of the New Venture Gear transfer cases.

Beginning Again – Happy New Year

2005 is now in the history books, and I hope all of our readers enjoyed the holidays. It is a time-worn habit to make resolutions and try to improve our situations for the new year.

Time is a human creation. All other forms of life and some primitive tribes do not have any understanding of time. They are driven by instinct, seasonal changes and their life cycles, but we are the only species that has created the concept of time. This ability to measure each day precisely and then make future plans is a blessing and, at the same time, the source of tremendous pressure, which is self-induced.