Shift Pointers

- Author: Pete Luban

So this late-model GM car with a 4T65 E comes into your shop needing transmission work, the transmission hits your bench and during disassembly of the transmission you notice that the plastic washer between the channel plate and the drive sprocket is destroyed along with that area of the channel plate.

No problem; you have a core that you can swipe the channel plate from and use it in this unit.

Let’s spring ahead to the point when the transmission has been re-installed, the car has been road tested and all is well – NOT!

The car is finished late in the day and therefore is not delivered. As the center manager goes to back the vehicle out of the shop, he realizes that he has to wait almost half a minute for the car to move.

In the parking lot, he pops the hood to check the fluid level, and it looks to be right on the money. He comes in and tells you what happened (oh no, not one of those days), and you go check it out.

After checking the fluid level for yourself, you see that it is correct, so you take the car for a test drive. The car clicks along like a fine watch; everything is working just as it’s supposed to.

When you get back to the shop, you suggest the car not be delivered until you can check it again after it cools down. You’re already suspecting the possibility of a drainback problem.

Let’s spring ahead again (if only it were that easy). The first thing you do when you reach the car is to check the fluid. Sure enough, it’s way overfull. Now you start the car up and pull it into gear – no movement. You try reverse – no movement. You give it some throttle – no movement. Suddenly you feel it ease into gear and it moves.

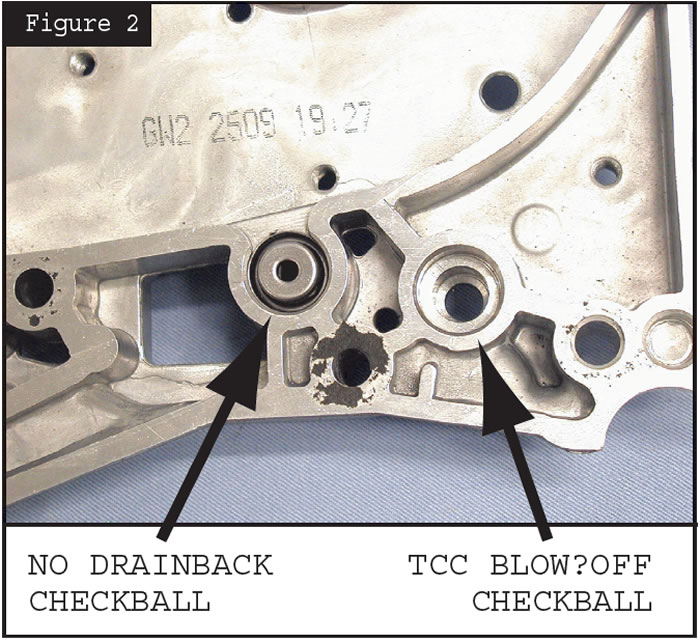

Well, the easiest thing to do at this stage of the game is to check the return cooler-line fitting in the bottom of the case.

When you unscrew the cooler-line fitting you notice that oil comes pouring freely. You now remove the cooler-line fitting, and lo and behold, there’s no #$^&*! checkball in the fitting.

You can’t understand how you could have missed that, but be that as it may, you find a cooler-line fitting with the checkball in it and install it.

Let’s spring ahead again (springing ahead is cool). You let the car sit for a reasonable time (too bad you can’t spring ahead), and now the dipstick does not indicate a severe overfull condition. Sure enough, the car moves as soon as you put it in drive or reverse – problem gone.

This one bothers you for a while, but as busy as the shop is you soon forget about it.

So what happened? Why the mysterious case of the missing drainback checkball?

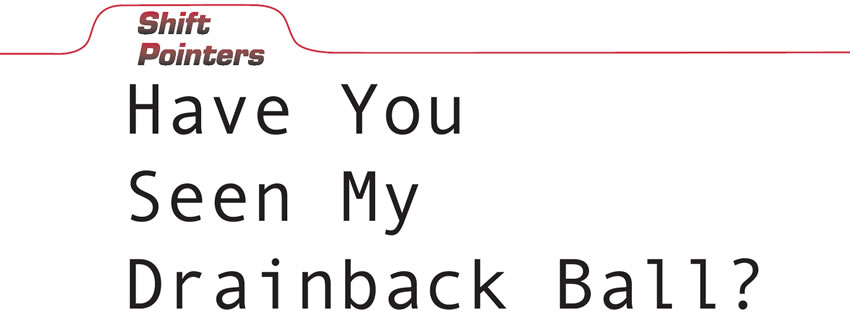

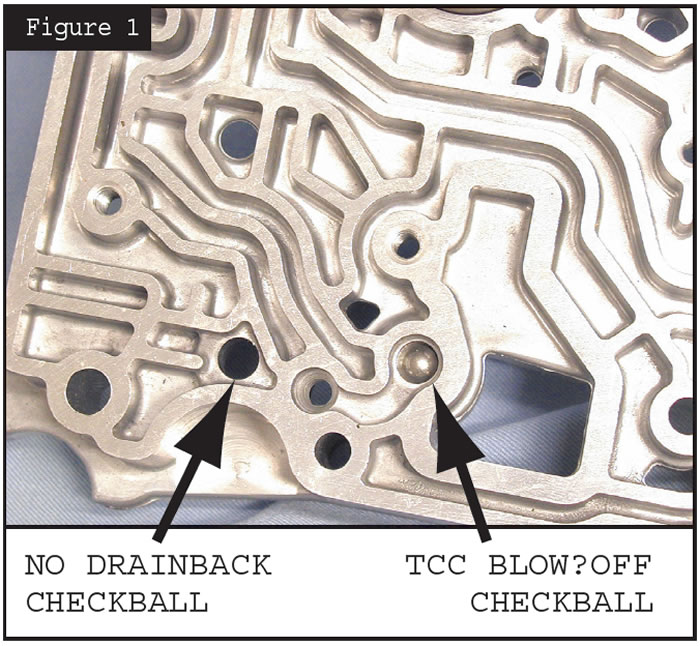

If you look at the channel plate in Figures 1 and 2 (remember that the channel plate was scavenged from a core), you will notice that there is an empty hole next to the TCC blow-off checkball capsule.

Not all channel plates have an empty hole here; some channel plates have a cooler drainback-checkball capsule here.

The original channel plate had the capsule; therefore, there was none in the case fitting for the return cooler line (see Figure 3).

The technician installed the channel plate in Figures 1 and 2, which also has no drainback capsule. End result: drainback!

This story is not over. Let’s suppose that the technician went the other way. Let’s suppose he used a channel plate with a drainback checkball capsule and there also was a checkball in the return cooler-line fitting. Would there be enough of a restriction to cause hard-part damage? I don’t know, because I haven’t seen it done, but the question is, Are you willing to take a chance?

Check your pieces and parts.

Until next time.