In the ongoing quest to improve fuel efficiency, domestic and foreign OEMs turned to Continuously Variable Transmission (CVT) technologies as a solution. In 1989 Subaru introduced the first modern automotive CVT in the U.S., the subcompact Justy model. Other automakers began developing their own CVTs throughout the 1990s and they are even more popular today in passenger cars, SUVs, and trucks. In addition, many of the new hybrid vehicles use CVT transmissions in combination with electric drive motors to improve efficiency even further.

Continuously Variable Transmissions (CVTs) depend on belts or chains running on metal sheaves (variable diameter pulley) to transfer the rotational torque of the engine to the front or rear drive axles of a vehicle. Because of this, one of the most important properties that a CVT fluid must have is the proper coefficient of friction. This is essential to provide the traction for the belt or chain to transfer the torque axially, but still slide smoothly radially on the sheave for seamless ratio changes, all the while providing adequate protection from wear on the sheaves and belts that transfer the power.

This high coefficient of friction of current CVT fluids (making it a “traction” fluid) prevents the metal belt or chain from slipping axially, or in the direction of rotation. If the belt or chain slips under acceleration or other high-torque conditions, there is a high potential for belt or chain wear, causing excess noise and drivetrain shudder unless the fluid is formulated to prevent wear while slipping smoothly.

Even without axial slip, the belt or chain must slide radially on the sheaves as they become wider or narrower and the fluid must provide lubricity for smooth radial sliding.

When CVT fluid is additive-depleted and sheared down, every ratio change contributes to chain wear and material deposition on the sheaves. Reducing wear, and correcting additive depletion are critical for CVT component longevity. Most consumers are not aware that the service intervals are required sooner and more frequently with CVTs than step automatics. Some CVT models require a fluid change every 15 – 20,000 miles. Even with these short service intervals, the fluids additive content tends to degrade faster, resulting in:

- Objectionable noise

- Shudder

- Poor performance

- Belt & chain slippage

- Foaming that causes improper fluid pressure and flow

- Excessive component wear

- Heat that creates sludge

LUBEGARD® CVT RECHARGE & PROTECT® #67010 is a concentrated additive, formulated to provide extreme pressure performance and anti-wear protection for sheaves, belts, chains, and pulleys in order to prevent slippage. It solves problems like shudder, noisy operation, and fluid foaming. LUBEGARD® restores the additive content to consumed CVT fluid and protects new fluid from breaking down as quickly by raising the thermal and oxidative stability of the fluid.

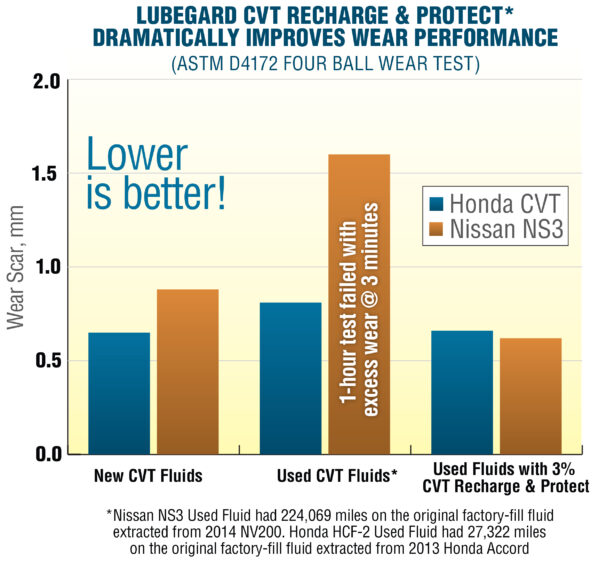

Testing shows LUBEGARD® CVT RECHARGE & PROTECT® dramatically improves anti-wear protection, even in used fluid. It restores the anti-wear properties of high-mileage, used fluid back to the same level as brand new, factory-filled fluids:

When it is time to change the fluid, LUBEGARD® COMPLETE™ CVT FLUID #68112 is the service solution for over 90 OEM CVT fluids! LUBEGARD® COMPLETE™ CVT Fluid is formulated to provide the frictional needs of the transmission for smooth sheave and belt operation while providing the highest level of anti-wear protection to assure long life and smooth trouble-free operation. LUBEGARD does not thicken at frigid temperatures for excellent cold temperature operation and provides superior anti-shudder performance.

Both LUBEGARD® CVT RECHARGE & PROTECT® and LUBEGARD® COMPLETE™ CVT FLUID are formulated with proprietary LXE®(Liquid Wax Ester) Technology that has a molecular structure that allows unsurpassed transfer of heat and cold temperature stability.

LUBEGARD® has been the #1 choice of transmission professionals for over 30 years! Visit our website at Lubegard.com for more information on LUBEGARD® additives and our COMPLETE™ line of whole-fluid service solutions.

This article is sponsored by LUBEGARD®.