Share What You Know: People Will Listen

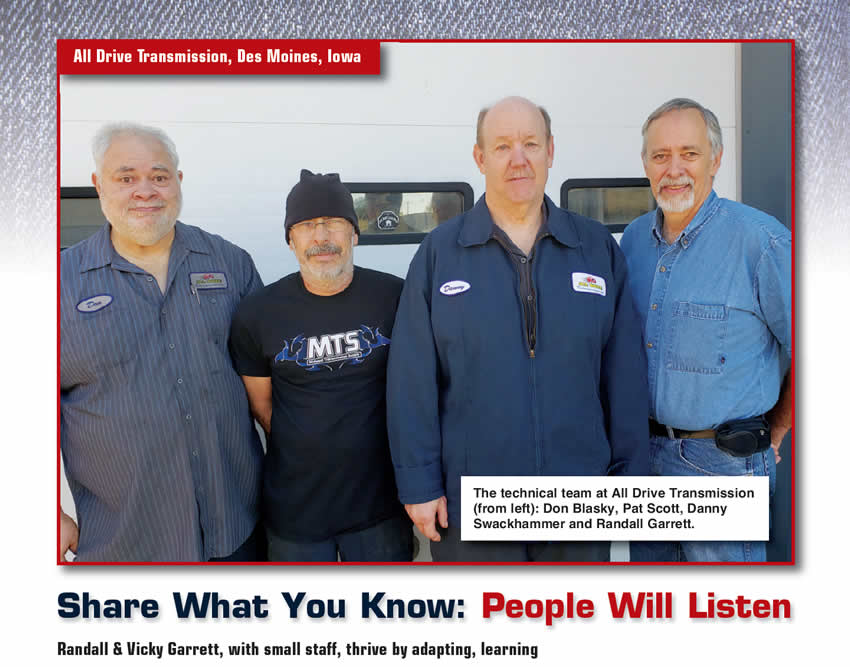

Randall & Vicky Garrett, with small staff, thrive by adapting, learning

The major repairs are getting less and less, and the small repairs are getting more and more, said Randall Garrett, owner of All Drive Transmission, Des Moines, Iowa.

“When we first started out, that was back when there were 350s and 400s, back in the ’80s. There was a lot of major rebuilding. We have more minor repairs now – electronic problems, speed sensor and solenoid problems,” he said. “We’ve had to diversify and get a little more involved with differential repairs and some light automotive repair.”

Randall is looking into expanding the amount of general repair work.

“At this time, it’s something we’re toying with, but as busy as we are, we have enough to handle at this point. If I were to add some technicians to take that on, that’s what I’m looking at.”

The shop has some important assets that are keeping the operation in good shape:

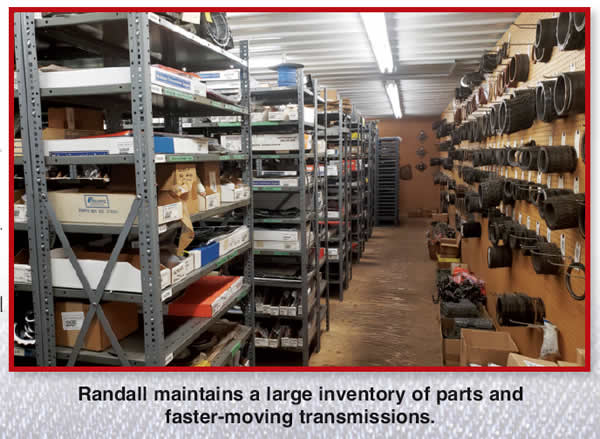

• Space for stocking parts and units: Randall keeps a large inventory of parts, and faster-moving transmissions are in stock.

• The willingness to work on all domestic and import vehicles as possible. They work on 1-ton trucks and F-450s and F-550s.

• An emphasis on training through ATSG and ATRA, providing a nationwide warranty and regular technical seminars

• The affiliation with Certified Transmission, providing quality remanufactured transmissions

• Long-time, capable technicians

Randall and a business partner opened the shop in 1984, bought property and built a small shop from scratch: a three-bay, two-man shop. Randall bought out the partner in 1999.

Over the years, he acquired more property and expanded the building twice, increasing the space by a factor of five. Now the car count is 20-40 per week from customers typically from a radius of 10 miles and others from 40-50 miles.

Retail & wholesale

Randall does not charge for looking at a vehicle.

“We don’t charge for initial inspection, road test or diagnosis,” he said. “We scan the vehicle, check it over externally, and provide from there a determination of what repairs may be needed. We don’t charge for that service, which brings a lot of people in. Some of them just want you to scan them and read the codes. We just do it because we like to provide this service.

“It’s something we like to do. Someone will call with a technical question they might have, some repair question, and we provide free information for that. It’s not something we don’t feel we can’t share. We share a lot of that.”

At All Drive Transmission, the breakdown of work is 65% retail, 35% wholesale.

“I seem to be a go-to guy for technical information on a lot of things. A lot of their customers have established a relationship where we handle a lot of their questions and help them with their work with their customers.”

Employees, owners

The Garretts work in the shop. Vicki, his wife, serves as a receptionist and bookkeeper, and Randall does transmission work and manages the parts inventory, among ownership responsibilities.

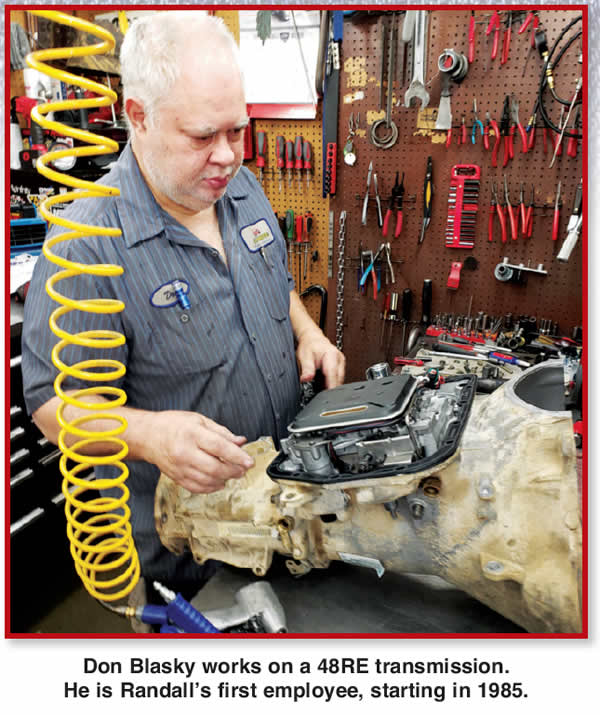

The small staff has been very loyal – such that Randall’s first hire, Don Blasky in 1985, has been working there ever since. “He’s a good friend and a good technician and someone we’re proud to have here,” Randall said, emphasizing that he’s pleased with the whole crew.

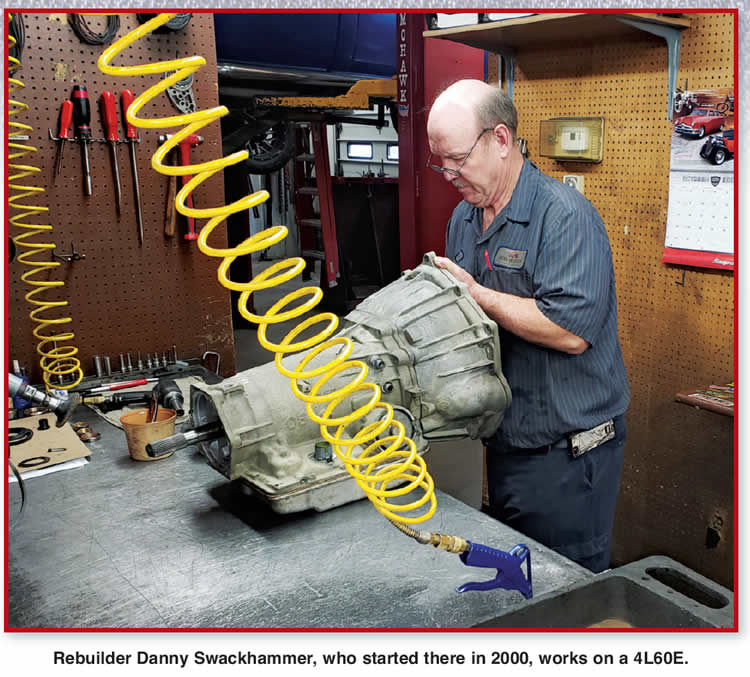

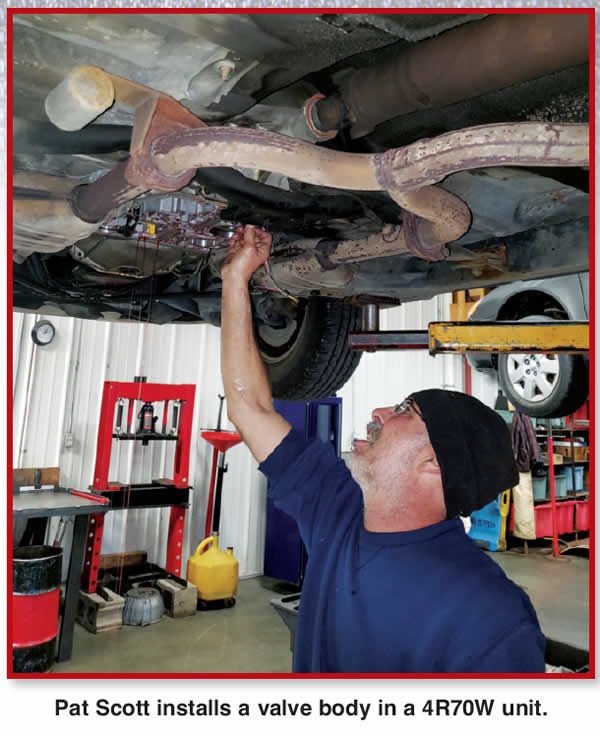

Don – and Danny Swackhammer who started there in 2000 – are the two rebuilders. They also pick up other kinds of work. R&R tech Pat Scott has worked at All Drive since 2002. All the technicians help with R&R and general service.

Must have parts, & more

Pondering how his shop stands out, Randall mentioned quality of work, reputation built over more than three decades, and customer service. One key aspect is ready access to parts.

“I started from a mechanical background. I didn’t jump right into ownership right off the bat,” Randall said. “As far as a technician’s standpoint, I’ve always been a real strong believer that you need to have the parts. You need to have the parts in stock in able to turn around the vehicles as quick as you could. A vehicle tying up your bay because you don’t have parts is costing you money, too. And the technician is able to stay focused on what he needs to do.”

Moreover, an owner must adapt to the changes in the industry. “Currently we don’t do hybrids,” Randall said. “We’re looking at doing more of that. If I had a technician with training in that area, we could do more with that.”

Affiliation with Certified Transmission continues to bring future-oriented outcomes. “A lot of units in the past were hard to price, with having remanufactured transmissions available, now I’m able to price up front what kind of repairs are needed and what they would cost.”

Beyond

The Garretts have not set plans for retirement, but they enjoy their vacation home in Arkansas. “We get down there when we can, and some day we’ll retire. I’d just dabble in what I like to do. I’ve done a lot of custom work on vehicles. We’re currently doing a ’64 Corvette for my brother-in-law,” Randall said. “If I retired, I’d probably do more of that kind of work.”

One thing that Randall finds satisfying that might delay retirement: surprising a customer who had been expecting the worst in the way of a bill.

“As I said, we’ve been doing a lot of minor repairs on vehicles than we ever have, and fixing a lot of things without a complete rebuilt. Sometimes they don’t expect that, and they’re super-pleased that we treat them right and try to care for them the right way.”