When conducting ATSG seminars, as we are usually covering a specific piece of tech, we’ll often tell attendees that if they put this together wrong, they should let us know what happens. Just recently, Ricky Hodgkinson from AACTION Transmission did just that. He was kind enough to share an incident he recently had with a GM 4T65-E transmission.

A recently rebuilt transmission was being installed, and as they were filling the transmission with fluid, it seemed to want to move forward despite being in Park. When they put it in Reverse it was bound up, while in Neutral it moved forward (the wheels were off the ground on the hoist). In Drive it would shift from first to second but then bound up going into third.

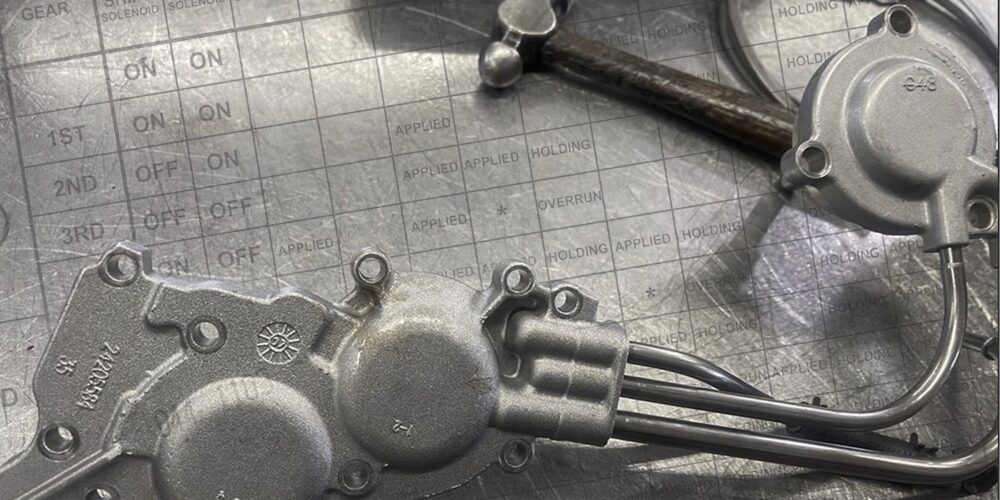

Looking at a clutch application chart in Figure 1, it shows that the input clutches are applied in Park, Reverse, Neutral and Drive first and second gear.

When everything is working correctly, with the input clutches being the only component applied in Park and Neutral, there is no movement. For this to have forward movement in Park and Neutral yet a tie up in Reverse and third gear, another component is being applied hydraulically or is stuck on mechanically.

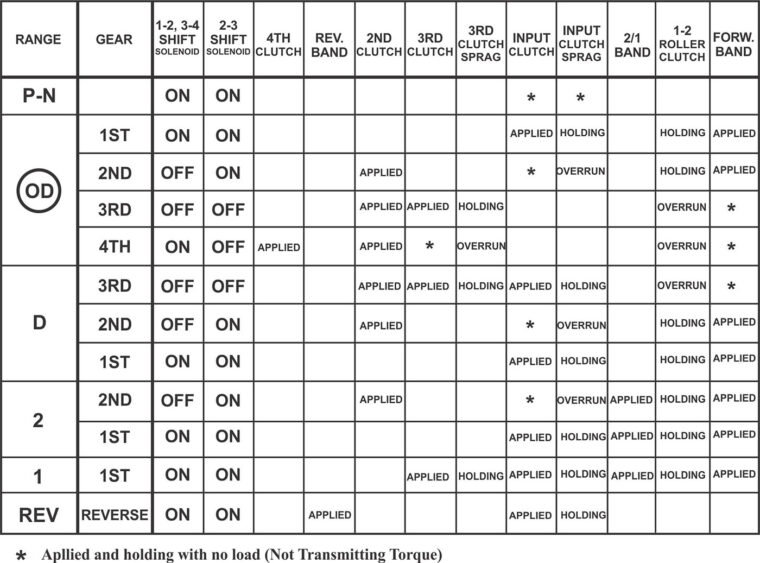

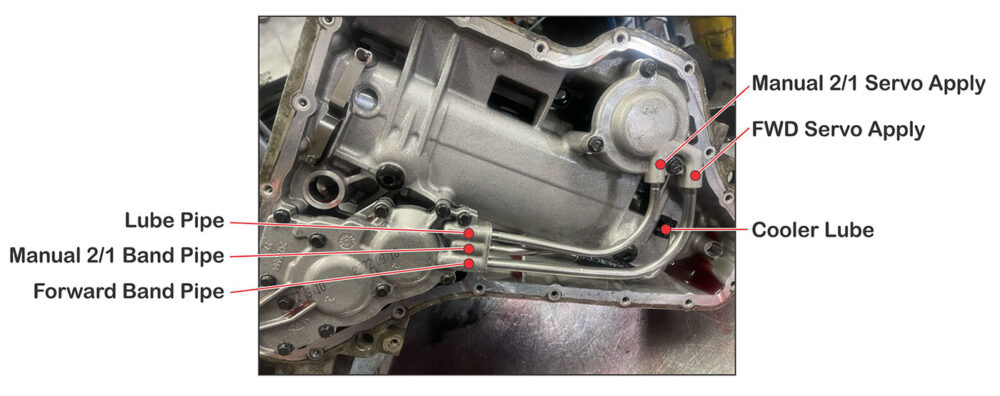

Looking at the application chart once again, the only component that would make sense is the manual 2/1 band. The band was first inspected to see if it was mechanically stuck on in some way, and it wasn’t. This confirmed there was a hydraulic problem taking place. This manual 2/1 band and the forward band are supplied with pressure through pipes that are attached to the accumulator assembly. The third pipe supplies cooler lube to the rear of the gear train.

Since Ricky knew he had these pipes out, he checked with an ATSG TechTran manual and discovered that he had inadvertently crossed the lube pipe with the manual 2/1 band pipe, as figures 2 and 3 show. This explains how the manual 2/1 band was applied at all times.

Normally, cooler lube pressure is very low. Once it leaves the cooler to go into the transmission, since it is used for lube, it dumps into the areas it is channeled to for cooling. There is very little back pressure. But with it dead-ending in a servo, the cooler circuit quickly builds up to whatever converter charge pressure is and the band applies. This is not good for the cooler or the converter.

Meanwhile, there is no lube oil going to the transmission unless the selector lever is placed into manual low. Fortunately, with the transmission exhibiting an immediate problem by wanting to move forward in all ranges, the engine was shut off preventing any further damage to the transmission.

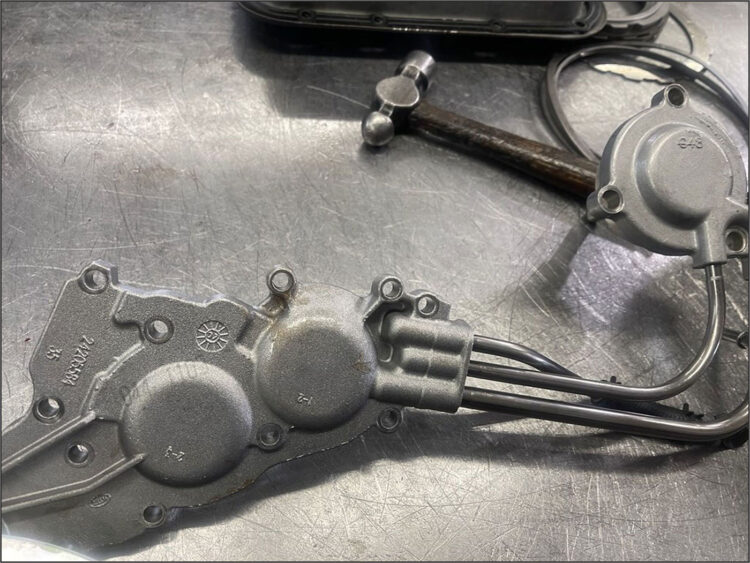

Once the pipes were relocated to their rightful place (as seen in Figure 4), the unit functioned normally. We thank Ricky for sharing this with us.

We had dealt with this mistake with others on our technical help line as far back as 2002, so Ricky wasn’t the first. Although we haven’t heard of this in quite some time, with many older cars being repaired these days, it doesn’t hurt to revisit what has been forgotten as preventative medicine.