Tech to Tech

- Subject: Low-beam headlamps inoperative

- Vehicle Application: 1996 Chevy Tahoe

- Essential Reading: Diagnostician

- Author: Brian Manley

Technician network is key in solving circuit problem

I recently had a vehicle in with a symptom that I thought would be an easy fix, only to have it take up several hours that I had not anticipated losing. Does this sound familiar?

The 1996 Chevy Tahoe had a customer concern of “No low-beam headlamps.”

“How hard could this one be?” I thought to myself. I started with the basics and confirmed that, yes, only the high-beam headlamps functioned. I performed a cursory inspection of the headlamp wiring to the bulbs, searching for any clues such as animal intrusion or substandard repairs. It all looked like it was original-equipment manufacturer and untouched, so I pulled the fuse cover and searched for the headlamp fuses. On this truck there was a 50-amp Maxifuse for headlamps in the underhood fuse/relay box, and a daytime-running-lamp fuse in the underdash fuse box. Both of these tested fine, so I performed my normal “running of the fuses” to ensure that I didn’t overlook a mislabeled blown fuse. I found no open fuses, so I went in search of information regarding the operation of the circuit and found no description on my aftermarket information system.

Next, I needed to pull up the wiring diagram to see all of the circuit components, which included headlamp and dimmer switches, two fuses, daytime-running-lamps relay, module and diode, fog-lamp switch and lamps, wiring, connections and lamps. In the world of copper wires and current flow, everyone is happy as long as there are no interruptions. That’s when we see the cars, when those electrons can no longer get to their designed destination, activating the circuit they were destined to complete.

I spent some time searching for the information needed, but – faced with a backlog of work to get done and a headache from either extended time inverted under the dash or a lack of calories, and since it was way past my lunch time – I decided to stop, grab some food and search iATN (International Automotive Technicians’ Network) for any more clues. I had gone there before, and I have had success searching the “Closed With Fix” section. Sure enough, after some sleuthing, I found a post by an iATN technician-sponsor from Pennsylvania named Bob Leonard, who had seen several of these trucks in his shop and had discovered his own pattern case failure.

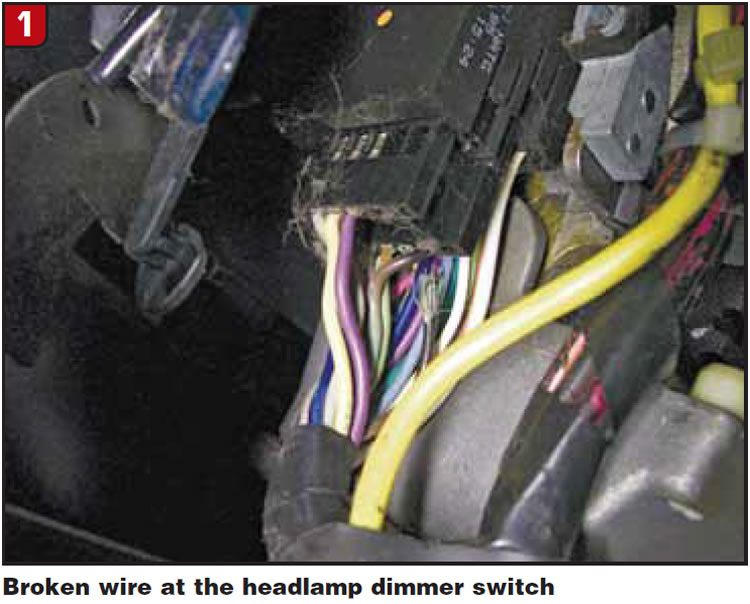

Bob said in his post: “I’ve worked on three vehicles (all the same year, type and options as subject vehicle) that were found to have an overheated wire – to the point of discoloration and breaking – at the turn-signal combination switch. The wire is a tan wire coming from the headlight dimmer switch to the daytime-running-light relay and is powered up in the low-beam position.”

I immediately got a little excited as I dropped my sandwich, grabbed my flashlight and dove back under the dash. Sure enough, twisted around behind the loom and covered by lots of camouflage was a completely broken wire – right at the headlamp dimmer switch! I made a temporary connection and immediately had low-beam headlamps. I was happy to have found the root cause, but why was there discoloration and corrosion at the point of the broken wire, along with both adjacent wires? I’m used to seeing green, fuzzy contamination in exterior locations where exposure to the elements is a big issue, but under a nice, safe dashboard? I searched in vain for the reason for the corrosion but found none. In fact, Bob’s post was the only one that pointed to the root cause.

Bob also said: “I found that some of the prongs on the DRL relay showed discoloration from excessive heat. I checked the rest of the system for excessive voltage drops but could find nothing out of the ordinary … I replaced the DRL relay on all three trucks as a precaution but would feel better if I could find the root problem.” I checked my DRL relay for similar signs of overheating, but mine looked just fine. I also checked for excessive voltage drops or current flow in the affected circuit without any strange numbers.

In a similar case study, I recall finding inoperative headlamps on another popular domestic brand that had me scratching my head for a while. After tracing many circuits and isolating an open circuit in a feed wire to the bulbs, I found a wire that looked normal except for some “bulging” in a remote section, not at a connector. The bulge was hard, and when I cut the insulation there was corrosion sufficient to stop virtually all current flow at that point. The wire appeared undamaged until I got to it.

Did this wire “wick” moisture along its length to that point? Was the wire manufactured with a defect? I never got my answer, and this repair, just as the one with the Tahoe, reminds me that high-resistance circuits can happen even without any apparent outside trauma. How many open circuits or high-resistance repairs have you made that resemble these two case studies?

I am grateful to Bob for leading me to the root cause sooner than I would have gotten there by myself. This is a great case study that underscores how important technician networks can be for the professional-technician community.

Brian Manley is a vocational automotive instructor for the Cherry Creek school district in Aurora, Colo. He is an ASE master certified automobile technician and a former member of the National Automotive Technicians Education Foundation board of trustees. You can reach him at [email protected].

The copyrighted article featured above is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive service and repair professionals, visit www.ASAshop.org or call (800) 272-7467.