Tech to Tech

- Subject: Engine miss

- Vehicle Application: 1998 Cadillac Seville

- Essential Reading: Diagnostician

- Author: Jeff Bach

Seville gets a lot of new parts, but the problem persists

When times get hard, people tend to do things themselves as much as possible before spending money to pay a professional. That’s completely understandable. It’s when they reach the point that it’s costing them more to do it themselves and yet they keep throwing money at the problem that I can’t understand. That’s the point where ego overrides logic. I guess once you get in so deep, it’s hard to cut your losses. It seems to me that it’s about the “twice-what-it-should-have-cost” point that I’ll get that phone call.

That call started on this ’98 Cadillac Seville with a 4.6-liter Northstar engine. The caller started out by saying, “I hear you are ‘The Man’ when it comes to fixing these Caddys.”

Stroking my ego won’t help me pay the bills, I’m thinking.

“I’ve fixed a few of them,” I say.

“Well, this one doesn’t seem to be responding too well to everything I’ve done so far,” the caller says.

“Tell me a little bit about what started going wrong with it and what changed, if anything, when the diagnosing began,” I say.

“Well, I first noticed a little rough idle when I came to a stop, then it started getting worse and I could feel it missing when I was driving,” he says. “I thought maybe it just needed a tuneup.”

I ask, “So what all have you done to it?”

“I tuned it up with new plugs, spark-plug wires, air filter, fuel filter and a new PCV valve,” he replies.

“Did that help it at all?”

“Not really,” he says. “A mechanic friend of mine told me these Caddys have a lot of problems with the injectors so I got a set and put them in. That didn’t seem to help either. Then I read on the Internet that they have problems with the crank sensors on these Northstars, so I put in a new set of them.

“That didn’t fix it either, so I also tried a new coil pack on it, since I saw online that they had problems with them, too. Now I’ve run out of things to try and everyone I call around here says to take it to you, so here I am.”

Because I’m familiar with this model of Caddy, a lot of thoughts are rolling through my mind – things like: Injectors don’t seem to be much of a problem with these cars, crank sensors didn’t start showing up as a problem with the Northstar until 2000. Head gaskets were a big issue on the ’98s, causing a miss, but that usually was limited to the first few minutes of driving – then the miss went away until the gasket got bad enough to start making the car lose coolant.

I thought about saying something smart like, “Good thing you didn’t step in it,” but I managed to bite my tongue and muster the words: “Looks like you’ve done all the hard work; now all I have to do is find the miss.”

He asks, “Can you hook it up to your computer and tell me what’s wrong?”

“We’ll hook it up to the computer, the scope and a scan tool. I’m sure one of these machines will tell us what the problem is,” I assure him.

It’s always a good out for these guys to know that some piece of equipment that they don’t have access to was required to find the problem. It has nothing to do with their diagnostic abilities. After all, they’re just doing what mechanics do when they get one in like this. They’re just saving us all that time figuring what is not wrong with the car.

After getting him to leave the car and call for a ride, I started thinking this would be a good car to do some basic testing on, using the same technology that the computer uses to determine which cylinder has a miss on OBD-II cars.

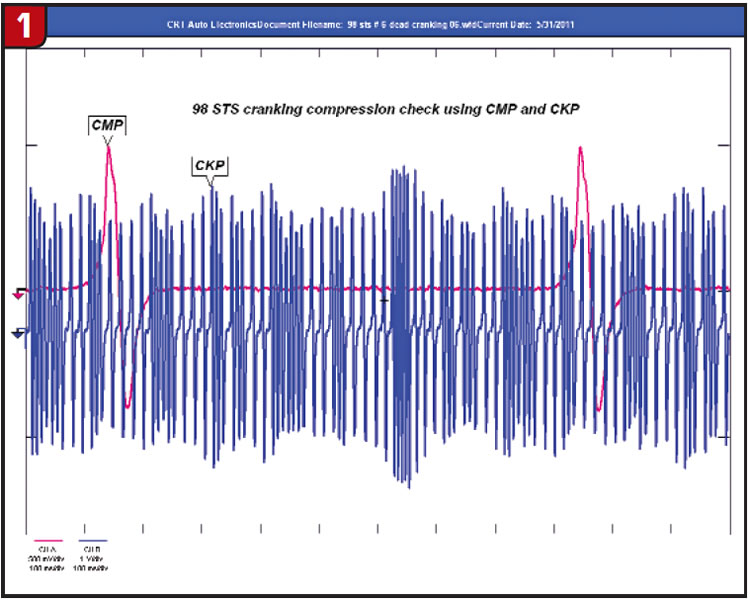

I began by connecting my lab scope to the cam-signal sensor and one of the two crank sensors that this Northstar uses to determine crankshaft position (CKP).

I started with a slow scope speed of 100 ms per division and disconnected the coil feed to get a quick check of the most-basic engine condition: cylinder compression.

The Northstar has a 10.5-1 compression ratio and makes a good car to look at using a scope because you can see a nice variation in the size of the CKP-signal spikes as it cranks. Since the CKP signals are generated by a variable-reluctance magnetic pickup, they get taller and closer together as velocity increases right after firing occurs on a running engine. Hence they also get shorter and wider as a cranking (spark-disabled) engine nears its peak compression.

In Figure 1, you can see an obvious difference in the heights of the CKP signals as each cylinder approaches top dead center.

You can already see, I’m sure, there are peaks and valleys and an obvious problem toward the right middle of the pattern.

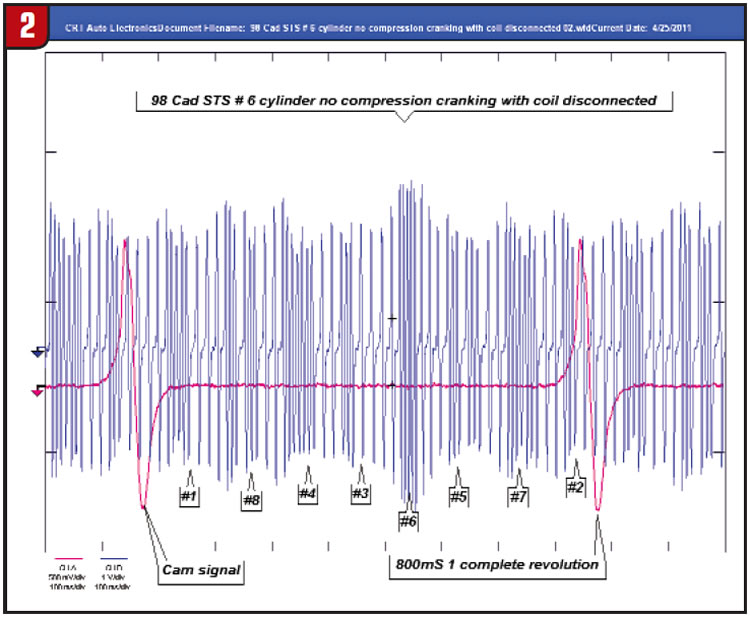

In Figure 2, I’ve added the labels for each cylinder’s compression to make it easy to see where the problem lies.

In Figure 2, you can see that it takes almost exactly 800 ms for the CAM-sensor signal to repeat. That is one complete revolution of the cam (twice for the crankshaft) in which all eight cylinders have been through their compression stroke. Starting with the one directly in front of the CAM signal (the first short, wide signal), if you measure out you’ll notice that the signals get short and wide at each 100-ms interval. Using this information, it soon becomes easy to see where the No. 6 cylinder’s compression stroke should take place. The signal gets taller and closer together, indicating that the crankshaft actually sped up at this point, which tells me that cylinder basically has little or no compression.

The miss mystery is nearly solved with a fairly quick and easy (not overly high-tech) scope test, which gives me pretty clear and undisputable factual documentation. This translates to me as “added value.”

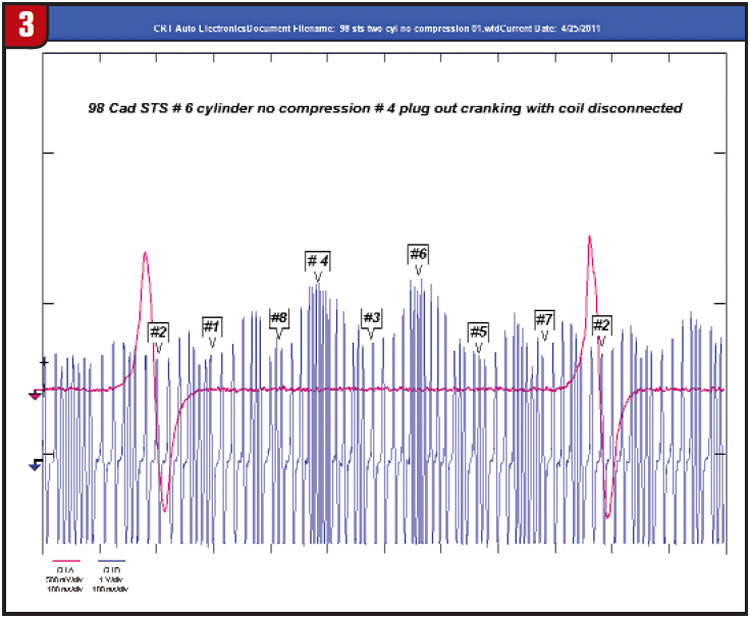

In Figure 3, I take the added step of pulling out the spark plug to No. 4 cylinder just to get a positive reference for compression comparison and cylinder depiction.

Notice that the heights and spacing of the CKP-signal lines for No. 4 and No. 6 are now nearly the same.

Using this as a comparison guide, it is a pretty sure bet that No. 6 cylinder has the same compression as No. 4 with the plug removed. Now that I know which cylinder is missing and that it has no compression, the question becomes: What is causing the No. 6 cylinder to have no compression?

We don’t as a rule see this as a common issue among Northstars, and very seldom if ever have I seen one with a burnt valve, even on high-milers.

A look into the cylinder did not show any sign of piston damage or scarring. I blew air into the cylinder with the engine on compression stroke and could hear it escaping through the intake. I started thinking about the possibility of an intake valve sticking open or being obstructed by something.

I contacted the customer and relayed my findings along with my suspicions. He was elated to know that I found the miss and gave me the OK to pull the intake and have a peek at the valves.

Once the intake was removed, the problem was revealed. The intake valve was nearly a quarter inch off its seat and being held there by what looked like a washer.

Upon closer inspection of the removed obstruction, I came to the conclusion that the washer came from the bottom of the plastic engine cover. The big question my new customer had was, “How did it get there?”

The last thing I am into is throwing someone else into the fire, especially upon pure speculation, so I told him: “That washer could have been there in the intake rolling around slowly, trying to make its way to that intake valve, since the engine was assembled. No way to prove when it got there or how.”

He was good with that and, I hoped, stopped trying to assess blame to someone. Once I got the thing back together and running, the miss was gone. I had fun, and the customer was happy – truly a “win-win” situation.

Jeff Bach is the owner of CRT Auto Electronics, an ASA-member shop in Batavia, Ohio. For more information on this topic, contact Bach at (515) 732-3965. His e-mail address is [email protected] and his Web site is www.currentprobe.com.

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.