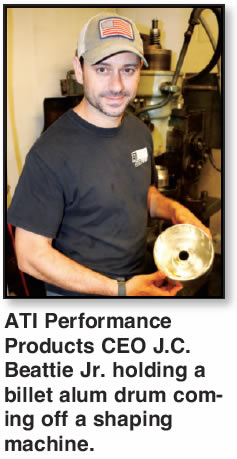

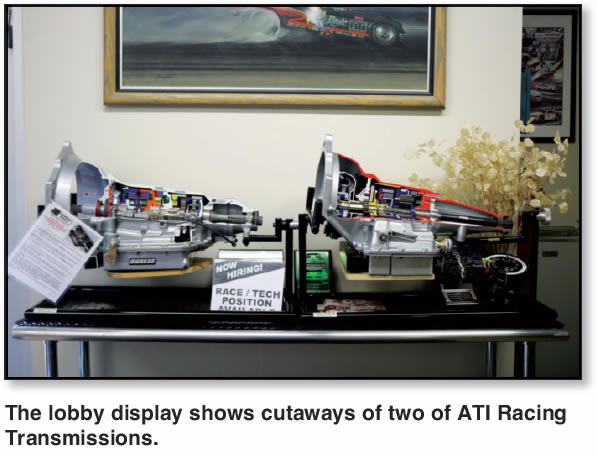

ATI Performance Products Inc.

“ATI Performance Products Inc., has been around a long time,” says CEO J.C. Beattie, Jr. “The start was a little transmission and general repair shop in Silver Spring, Md., where my dad (Jim Beattie) was in business with a partner for the first few years. That shop, ATI Transmission, is still in business there today. The business was a small general repair type shop with a large fleet customer, Yellow Cab in D.C. There was a lot of transmission work there, Powerglides at first and later 350s and 400s.

“Dad said that in the old days he’d come in some Monday mornings to find cars lined up around the block. To keep up with the work they hired mechanics to keep the place going 24 hours a day as these cab drivers just wanted to be back on the road. Often it was just a case of dropping the pan, draining the sludge, change the filter, refill the fluid and send them on their way.

“We had two big tanks of transmission fluid in that shop. Dad used to say one was Type F and the other had Type F! The business has grown from there. The same transmissions he worked on then are the transmissions of choice used in high-performance drag racing and by most street rodders today.

“I’m 39 now and I’ve been here for 17 years since graduating from college. But truthfully, I’ve been involved for virtually my entire life. Even as a kid, if we got out of school early or didn’t have school, this is where we came. It’s the same for my kids now. It’s a family business; Mom’s office is up front and my wife works just down the hall, and Dad’s was around the corner in the sales room.

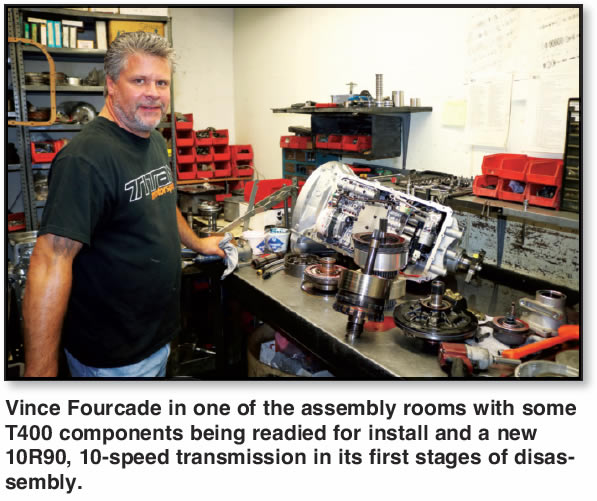

“Powerglides, 350s and 400s were there in the ’60s; and they’re still with us today. The 700s, 4L60s and 4L80s don’t get used on the track by the bracket racers, but you’ll often see those in street-performance cars like a guy who has a GTO that he maybe wants to race on the weekend and drive the car home.

“The mainstays are the Powerglides, 350s and 400s. The Powerglide got its ability to handle the higher horsepower from the introduction many years ago of the first aftermarket case. That case allowed guys to up the line pressure to get more out of those units. Then came stronger parts like input shafts, gear sets and that sort of thing.

“Today, ATI can hand a customer a 100%, brand-new, American-made high-performance Powerglide, that can handle up to 3500 HP. I remember asking dad when we started supplying the COPO Camaro program in 2012 if he ever dreamed he’d still be selling new Powerglides to General Motors? We can do the same for the 400s today as well.”

ATI is located in suburban Baltimore and employs 65 people. A recently purchased 100,000 square-foot facility is located across the street from the current 43,000 square feet the company occupies across two buildings.

“The next phase of the move is going to happen in the next eight weeks, with converters, transmissions, gear sets and valve body operations heading over. “We’ve already relocated shipping and receiving to the new facility. It’s something we have to do for the space but we’re looking at moving a lot of equipment including 30 CNC machines.”

And J.C. says that once the move has been made, the current facility will be used for overflow that he already sees coming.

“Five years ago,” continues J.C., “we designed a bigger, better, stronger case that we were able to get out first to the race tracks for the 400s. With that case we were able to increase line pressure without blowing the lugs out of it. We can send a 400 out of here that’s good for 4,000-horsepower, with an 1.187” Vasco input shaft, a large main shaft and parts like that capable of handling the increased line pressure at 300 pounds. Line pressure for a transmission builder is like new tires for a circle track car; everything gets better: the trans-brake is faster; apply is faster, release is faster, shifts are immediate and everything’s better reacting. We can machine the case’s valve body worm tracks however a customer wants them, and then we can build everything else up to their desire.”

“Dad had a long-time theory that he didn’t want to sell parts we manufactured for our converters and transmissions because then the competition would have access to those parts, which he believed were the best available. He preferred to sell the entire unit. I’ve opened that up to the point that just about anything made by ATI is available to the racer and nearly everything, including our lock-up products, are available to rebuilders.

“Dad’s theory was good before the days of the Internet, but now, everybody’s a Google expert and can find something that looks just like ours. Often we find it’s a picture of our product on somebody else’s website. The difference is that you won’t be getting an ATI input shaft or other part that we built here. You’ll likely get a knockoff made somewhere in Pakistan, India or China.

“The performance aftermarket suffers from having look-alike parts that have very different metallurgy or quality standards with pricing that’s all over the place. I mean you can find a clutch hub that looks like the one that costs me $85 to manufacture and somebody’s selling a $15 look-alike. It won’t hold up like the one we make, it won’t be as concentric and true but those parts are everywhere. A lot of those parts will last a drag racer a couple of seasons where an ATI part would last five or six, and not cause other issues.

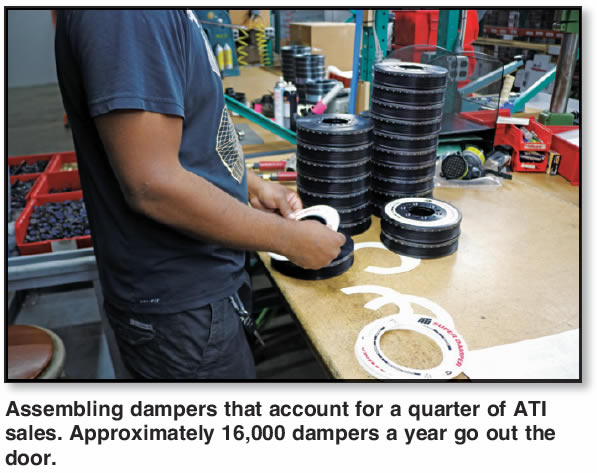

“I look at the Super Damper business we have from the NASCAR world. They do 3.5 million engine cycles, under full power, in a 500-mile race weekend. For a drag racer to do that it would take him 10 years of racing two days a week. So, a knockoff part that lasted a couple season for the drag racer would fail in lap 21 of the first practice of a NASCAR race. When a customer calls ATI they can feel confident that they are getting a high quality part that will outlast anything that comes from overseas.

“Our bolt-together converters weren’t the first ones, but we changed what was done and made it better rather than copying somebody else’s unit. We feature a full-billet cover with 10 bolts in the smaller one and 12 in the larger one. It’s amazing what a little engineering can do; some of the bolt-togethers have as many as 36 bolts.

“We manufacture everything in the line here. Now we often will outsource a rough forging that we process and finish. But the point is that the work that makes a difference to the performance of the finished product happens where we can see it and touch it and make it to our exact specifications.”

“ATI Racing Transmissions’ most popular units are Powerglides, 350s or 400s. At one time we had the C4/C6 units but that’s pretty much a niche market where the rules of competition dictate those units must be used. Most would choose the 400 or a Powerglide if given the option. We do the adapter kits and have many custom bell housings so that you can bolt direct to a Ford Small Block, Big Block or Chrysler with the flex plate, hardware and crank adapter and then use a standard Chevy converter.

“As far as manufacturing component parts go, dampers are a big part of our business. It takes four parts for each damper and we offer 450 different damper part numbers stock and we have over 1,500 different custom dampers available. The Super Damper makes up a quarter of our business, transmissions another quarter, converters is a quarter and the rest is our equipment and some what I call parts and pieces that we have in the catalog.

“As soon as we’re moved I’ll be working on the ‘parts and pieces’ and we want to add the GM six, eight and 10-speed units in the near future. That’s not necessarily for drag racing but will give a guy the ability to have a 1,500+ horsepower street car with an eight or a 10 speed that he can take to the track, beat on it, and drive it work the on Monday.

“We bought a ZL1 Camaro that we’ve had to the track with the new 10-speed transmission. I’ve worked on it with HP tuners, tuned on the transmission to make it shift quicker, better, faster and we are working on the converter. I have an 8L90 mated up to a new LT4 that will be getting flogged and a 6L80 that we’re using to develop those high-performance parts. We already have a bolt on SFI bell for the 6L, and 4L60 and 80 units.

“Guys overseas like that stuff a lot. That’s a whole different market where they put a 400 behind a Nissan TB48 or a Toyota 1FZ45. When somebody asks if we can make a part to a specification, I probably say ‘yes’ more often than I say ‘no.’”

Beattie Jr. says he isn’t an engineer and points to the nuances of differential equations as the reason he never pursued such a degree past the second year of college. “But,” he says, “my engineering degree is that I grew up here. I always do the initial designs on our parts with the guys here and then an engineer will verify and finalize before we manufacture a part.” We are lucky to have some great long time employees that really help keep ATI ahead of the curve.

Concluding, J.C. reflects on the goal of keeping personal the marketing products in an often online world. “I place a lot of ads in magazines and internet publications. We sent about 35,000 copies of our catalog out twice a year. We generate a lot of direct sales; however, we don’t actually sell on our website. That may be behind the times but I think our customers are a lot like myself and they want to get a person to confirm when something will ship and when it’s going to arrive and that its actually in stock and not just a number on the screen.

“Even selling a T-shirt is a challenge to get correct the size, color, style, shipping preferences and payment methods. So, imagine selling a specific input shaft for a PG when there are six different ones for different units. Often times the customers don’t know exactly which one they have, had or need and they’d order something that didn’t work and then they aren’t happy with us. At the end of the day, if someone isn’t 100% satisfied, they can get me or my mother on the phone. While we are open to developing systems for online ordering in the future, we don’t ever want to lose the close relationships we’ve formed with our customers through the years.”

In its formative years, ATI’s product line was dominated by torque converters. Jim Beattie was known for manufacturing converters robust enough to function under the high horsepower demands of drag racers. The building of converters led to the development of ATI’s line of converter rebuilding equipment.

J.C. comments, “Our equipment line is everything needed to remanufacture torque converters from start to finish. We sell the lathes with tooling and inserts, bonding machines, a pass-through washer, balancers, leak testers and welding machinery. We produce all of these here in the plant as well. Flat bar stock pieces of aluminum come in and we machine them. Everything is done right here so that when it’s Friday at 4 p.m. and you need something for your converter machinery, you’re talking to the manufacturer and the parts can still be shipped today!

“We don’t remanufacture stock replacement, OEM-style converters here; we build race converters. We do lockups with billet covers but we don’t necessarily have one of everything new to look at from the OEM’s. My basic offer is that whoever sends me the input shaft and stator tube for the first of a new converter gets the tooling free. At that point we’ll add that unit to our product line. So, anybody who needs to buy the tooling can and it will be included with all new machines.”