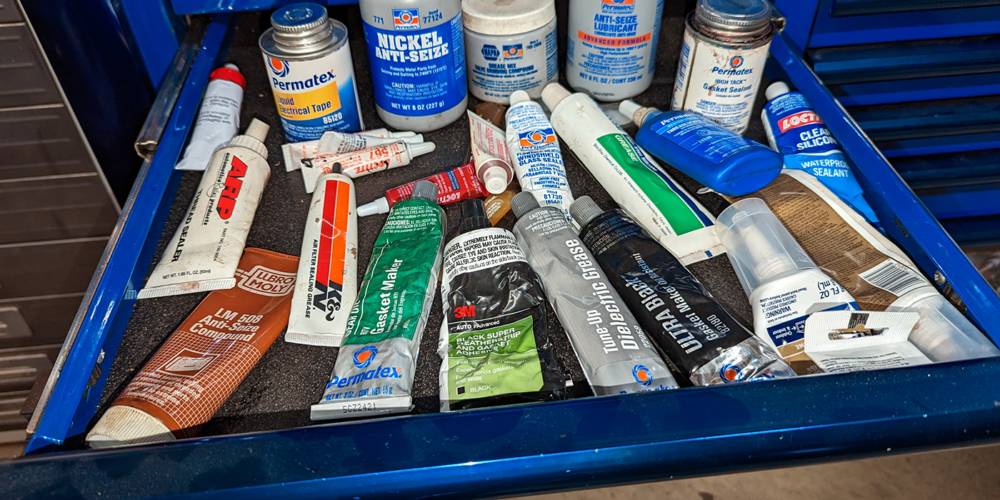

Every shop has a special location. Sometimes it’s a shelf, sometimes it’s a drawer. It’s where we keep all the “tools” that come in a tube. They’re usually community property, except for the occasional extra expensive items that reside in a manager’s office.

Of course, I’m talking about sealants, anti-seize and thread lockers, the chemical consumables that are just as valuable to our job as our hand tools. Often, they have a humorous side, especially when we see it mis-used, like more bright orange silicone sealant squeezing out between two components than would be needed to do the job five times.

And inevitably, there’s the stuff that gets used infrequently, ending up on the bottom of the drawer, eventually hardening up. But nobody throws it away and five years later, it’s still taking up space. It’s such a letdown to see it and think “oh good we’ve got some,” only to find out it’s hardened up. But, if you’re lucky and you only need a small amount, it’s still good in the bottom of the tube and you can poke a hole in it and squeeze it out the bottom. It’s a re-occurring cycle that can be both funny and frustrating. We put up with it though because we need all this stuff!

These “tools” are more than just a remedy or solution, they are as advanced as the modern cars we work on, and they’re part of assembly for many areas of a vehicle as they roll off the assembly line, making them an integral part of the repairs we do today. But just like a nut or bolt is different, so are they. They’re designed for very specific purposes, and using the correct one is just like using the right tool for the job.

Sealants

Sealants or gasket makers are more often referred to as “RTV” or sometimes simply “silicone,” but it’s important to be familiar with the different varieties. There are three groups of sealants: RTV silicones, anaerobic sealers and solvent based sealers.

RTV stands for room temperature vulcanizing, meaning it begins to cure immediately when it’s exposed to air. There are many varieties of RTV silicones, and choosing the correct one is based upon the application. Since new car manufacturers have been using these more and more, it’s important to reference factory service information and use the exact type when performing a repair.

The factors that differentiate between RTVs are primarily the fluids you are sealing against, the temperature at which the component will operate, the pressures that will be exerted on the seal, the compatibility with sensors and gap tolerance. The pertinent information is clearly displayed on the packaging of an RTV silicone, to make it easier for selecting the correct product.

Some RTVs are designed to cure quicker than others, and this is also an important point. You should always follow the recommendations for cure time before putting the component into use, or it simply won’t work as designed. Some may require as long as 24 hours before they are fully cured. Select the proper sealant based on the amount of time you have to do the repair.

Anaerobic sealers will only cure in the absence of air and the presence of active metal. They will not begin to cure until two metal mating components are assembled. They are primarily designed for assemblies with closely machined surfaces, and for applications where exact tolerances are critical.

RTVs won’t work where anaerobic sealers are called for and vise-versa, and this is where it’s important to reference OEM service information if there’s any doubt. Use anaerobic sealers when they’re called for but again be sure to confirm the correct type. Some anaerobic sealers are designed as gasket makers and some specifically as flange sealants. Some are only designed for specific metals as well, so be sure to check compatibility.

Solvent-Based Sealers are recommended for applications that come into contact with gasoline, and common uses are antique cars, powersports and small engines.

As easy as it sounds, mistakes do happen and there’s a few things to watch for when using sealants. First of all, don’t use too much. As I poked fun at earlier, too much sealant looks silly, but it’s more than that. Not only is it a waste, but it will squeeze out on the inside as much as it does on the outside, easily blocking passageways and potentially causing serious damage.

Gasket makers have many advantages. They seal gaps and imperfections, they’re more flexible and they last longer than most gaskets, but don’t use them to coat gaskets or hold them in place, a common mistake. They’re too thick and not designed for it. Gasket sealant, usually a spray, is a thin adhesive designed specifically for this purpose.

Anti-seize

You will hear anti-seize referred to as either a lubricant or a compound. Either way it makes sense because it is both. It’s simply a mixture (compound) of elemental particles combined into a carrier that is typically a type of grease (lubricant). The general make-up also includes rust, corrosion and moisture inhibitors.

It’s primarily known for its use on threaded connections, but it’s designed to lubricate, seal and protect any type of metal-to-metal connection such as press-fits, bushings, sleeves or keyways; anywhere the possibility of rust, corrosion or galling exists.

In addition to nuts and bolts that have high exposure to the elements, it’s also commonly used in high heat areas such as exhaust components or spark plugs. Opinions and usage vary between technicians; some hardly touch it, and some go through it like ketchup on French fries.

The reality is most of the time it’s either under-used or over-used and that goes for the when and where but also how much. There are three types of automotive grade anti-seize you’ll use: aluminum, copper and nickel, all designed for different applications.

I specifically say automotive grade, because while some of these cross over into uses for powersports and marine, I like to be clear that anti-seize lubricants are very specific to application. Marine grade, aircraft grade, food grade, nuclear grade, and various non-metallic grades are just the tip of what you can get.

No different grade is better than another, just different. For example, nuclear grade anti-seize has the completely wrong properties and formulation for the automotive industry and vise-versa. For the automotive industry, aluminum, copper and nickel is all you need.

Aluminum anti-seize is typically a blend of aluminum, copper and graphite lubricants. It can withstand temperatures as high as 1600 degrees F and is generally the “all-around” anti-seize you can use for standard fasteners, brake components, suspension components and some engine fasteners. It is more effective at preventing galling and corrosion due to weathering and chemical exposure.

Copper anti-seize is typically a copper and graphite blend, withstanding temperatures up to 1800 degrees F. It provides higher electrical conductivity than other blends and is more effective against corrosion and galling where high temperatures are present.

Nickel anti-seize is typically a blend of nickel and graphite and has the highest temperature rating, as high as 2600 degrees F. It is recommended where copper contamination could be a problem and is commonly used where extreme temperatures are present. It is also the best type for titanium, stainless steel and nickel alloys.

Anyplace where heavy corrosion occurs making disassembly difficult is a good location for a thin layer of anti-seize during reassembly, but don’t use too much. Anti-seize is designed not to wash away or wash out and it only takes a thin layer. If it’s squeezing out and dripping, it’s way too much. It can be used between components where corrosion was present, or on the shank of a bolt where no threads are present, so it doesn’t affect the torque of the bolt.

It’s common and acceptable to use on threads, but the most important factor to remember when using anti-seize on threads is what does the manufacturer recommend? The reason is torque. Since anti-seize is a lubricant, if it is used on the threads of a fastener, it will change the torque. You could over-tighten a fastener this way and damage the threads, weaken the fastener or damage a component, so use caution here.

A tip for applying anti-seize, especially on threads is to use a small stiff-bristled paint brush, or an old toothbrush. Anti-seize is a little thicker than grease and in order to get proper coverage you need to make sure you have applied it to all areas, just threading a bolt in may not be enough to distribute it across the threads.

Spark plugs are a common point of use, but it’s not always correct. The easy way to tell is if the threads on the plug are silver, cadmium or gold in color, don’t use it. These plugs have a coating that is designed for the application and cylinder head material they are intended for. The use of anti-seize will affect the torque and you could potentially damage the plug or cylinder head.

If the plug threads have a black oxide finish, it’s ok to use anti-seize, but use it sparingly, and copper is the best for this application. Oxygen sensors are also a common use for anti-seize, and many come with a small tube in the box. Copper is the best type to use for them.

Thread locker

Thread locker has the best name in the business. That’s what it does, and it does what it’s called. Period. It prevents fasteners from loosening caused by vibration or heat cycles, and it seals the threads against corrosion from outside elements such as water or chemicals.

It’s just as important as with any other chemical tool to use the correct one, but with thread lockers, it simply comes down to how strong they are and what they are designed for. There are standard colors that indicate their strength, making it easier for us to identify the correct one.

Blue thread locker, often called medium strength or removable, is designed for a smaller size range of fasteners, and fasteners with blue thread locker can be removed easily by hand. Red is known as high strength or permanent. It’s designed for a larger size range of fasteners and requires heat to remove.

These two types are the most common for automotive repair, but keep in mind there are many others including low strength, high temperature and penetrating grades. Purple and green, low strength and penetrating respectively, round out the other colors you may need from time to time in automotive repair, and if one of these special grades is recommended by an OEM, then it’s important to use it.

Pay close attention to what you are using, however, because there can be different properties within the same color family depending on the source, and sometimes the color of the bottle reflects the color of the thread locker; sometimes it doesn’t.

Thread locker is also an anaerobic sealer, meaning it cures in the absence of air, so it won’t begin to cure until the fastener is installed and tightened. When applying thread locker, all threads or surfaces should be clean and dry. Only a small amount is needed on the first few threads of a fastener, and all threads will be coated as the fastener is installed.

Though it may not cure completely for 24 hours, most thread locker will cure adequately during the repair process, so there’s no need to wait to return a vehicle to service. Each different type has a specific curing time, and this should be considered if you feel it’s a critical application.

Since anaerobic sealers rely on the presence of active metal, and some common fasteners we use like stainless steel and zinc are not considered active metals, these require the use of an anaerobic activator for proper curing and strength.

One final word: avoid touching the tip of the thread locker bottle to metal. Contact with active metals may cause it to harden in the tip.

This article originally appeared in our sister publication, TechShop.