“Our goal is to be very competitive with the aftermarket in all aspects of all service products that go into Ford and Lincoln vehicles,” explains Lisa Fournier, the team manager for powertrain and collision products. This includes a very substantial product assortment available to shops engaged in powertrain repair and rebuilding. The local Ford and Lincoln dealerships serve in the role of parts distributor to literally thousands of shops throughout North America.

Sue Jones, product team leader for powertrain components, emphasizes the breadth of product lines.

“We supply parts through local dealerships, including internal components, hard parts, kits, frictions and steels, electrical parts and the loose torque converter. It’s most everything that a shop will need to rebuild a Ford transmission in-house. While availability varies from unit to unit, our goal is to be able to have all the components and the kits for a particular transmission for 10 to 15 years after its last use in a production vehicle. We still have, for instance, an inventory of parts for the 4R100, 4R70 and 4R75 four-speeds.

“As far as kits are concerned, a Motorcraft transmission overhaul kit contains most everything an aftermarket rebuilder would need to rebuild a unit. We have currently two levels of kitting: a gasket and seal kit and the master overhaul kit. In the past we offered a third level, a less-steels (banner) kit. The less-steels kit saw diminished popularity as we observe that for today’s aftermarket rebuilder, the master rebuilding kit is the kit of choice. Every component in the kit will be the same part as is specified for use in the OE transmission.”

Jones adds that her program maintains a product line of five-piece clutch kit (disc, pressure plate, two bearings and the alignment tool) inventories for vehicles with manual transmissions. Newer units, she said, will also include a slave cylinder.

“Based on our planning,” Jones continued, “our goal is to have kits available by the end of this year that will cover all applications in Ford vehicles manufactured through model year 2013. The engineer on my team who, in concert with product development, is responsible for creating the aftermarket kit bill of materials used to package those products. Additionally, if the transmission engineers update or improve a part, those changes will be incorporated into Motorcraft overhaul kits as well.”

Also available through the dealership network are Ford certified remanufactured units. “Our remanufactured automatic transmission program is housed in Oklahoma City, contracted to ATC Drivetrain, a remanufacturer long known for top quality product,” explains Dave Gregoricka, who manages the remanufactured transmission program.

“That facility remanufactures transmissions for applications including passenger car, light truck and even F-650 and F-750 medium duty trucks that use the 6R140 transmission. Torque converters are included with these units as well as for sale as individual components and are remanufactured by a Ford certified remanufacturer located in Michigan.

“Each unit is remanufactured according to Ford engineering specification and the components are replaced or inspected and replaced as needed. If our OE assembly lines call for an improvement, that same improvement becomes part of the process for the reman unit. The process of improvements often continues after a particular transmission is no longer used for production vehicles but continues to be available as an authorized remanufactured unit.

“Each of the remanufacturing lines has a monitor that is used to display the bill of materials and operator instructions. If improvements are made by the Ford engineering team, it shows up on those monitors and is implemented into the remanufactured units.

“When internal parts are replaced, we apply the same OE standards used in selecting parts for production units. Finally, the unit is filled with the proper amount of OE factory specified fluid before it leaves the remanufacturer.

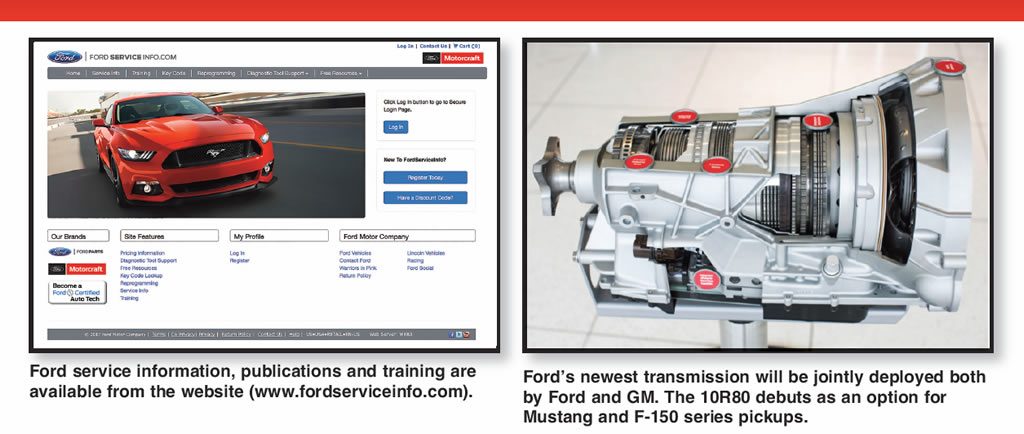

“Transmissions are dyno tested at the end of the line. Drive audits are also conducted on a regular basis. The drive audit procedure entails pulling a unit from the end of the production line, installing it in a vehicle and then driving the vehicle to monitor proper shifting and performance. Depending on the volume of units produced, daily drive audits are conducted.

“There are about eight or 10 service bays in the drive audit shop and we keep those people and that facility busy making sure that the remanufactured units perform according to Ford specification in the vehicles for which they are intended.

“Our certified remanufactured transmissions are considered complete with all solenoids, external sensors and the torque converter included. This is different from some units available in the aftermarket that may or may not contain all of the related components.

“Much like the purchase of a crate engine, newly manufactured service transmissions are available from Ford from the time a unit is being deployed on production vehicles and while any inventory remains thereafter. After those are gone, remanufactured units are available through the Ford dealer network.

“Units that we’ve built and have on the shelf ship same day. If a unit ordered has to be built, then our goal is to ship that unit within five days of receiving the order.

“It is common to have high-volume units in warehouses maintained by one of the three Ford Authorized Powertrain Distributors (PTD). In that instance the order is forwarded from the powertrain order center or dealer to the PTD and will, in most cases, be shipped out on the same day,” adds Fournier.

Continuing, Gregoricka observes, “Our plan calls for the remanufacturing facility to have a month’s supply inventory of finished units on the shelves at any point in time. In addition to that inventory, the PTDs maintain inventory for immediate shipment to customers. They’ve been very good about having the right unit in place for handling orders. All remanufactured units include a three-year, unlimited mileage warranty. Component parts include a two-year, unlimited mileage warranty.”

Gregoricka replaced Sue Castleman as team leader for remanufactured transmission units. Castleman now serves as sales manager for the company’s service information function that makes technical support resources available to the independent aftermarket.

Castleman says that resources available to our dealers are also available through the Motorcraft service site: www.motorcraftservice.com. “The site brings together a variety of technical support products aimed at the independent aftermarket shop, she told Transmission Digest.

“Service information for various transmissions and transfer cases is available by purchasing a subscription that is available for terms ranging from 72 hours to an entire year. These subscriptions cover most models and model years of Ford Motor vehicles. The information includes workshop manuals, wiring diagrams, Powertrain Control/Emissions Diagnosis (PCED) manuals, dealership service bulletins and TSBs. This is a library with easy search and lookup features that contains virtually all the information that is available to Ford/Lincoln dealer service departments.

“Also posted at the site are a number of online technical training courses that cover everything from very basic service topics to more involved technical issues. Courses of particular interest to your readers include the course on automatic transmissions that includes disassembly, assembly, inspection, measuring and critical adjustment procedures. A similar online course is offered for those repairing or rebuilding Ford manual transmissions.

“Finally there is support for a trio of diagnostic tools available from Ford Rotunda each making use of the IDS software package that, with a subscription, can be downloaded from the site.

“The original Vehicle Communication Module (VCM) tool is site-supported albeit the unit itself has now replaced by the VCM II, also supported on the Motorcraft Service Site. The VCM and VCM II tools communicate with Ford vehicles through the 16-pin diagnostic link connector. This device is used by the IDS software package and is the core of vehicle diagnostics to read trouble codes, reprogram (flash), and view vehicle data.”

Also available through Ford Rotunda and supported on the site is the Vehicle Communication & Measurement Module (VCMM) that uses the software and connects to a laptop and offers testing of fuel and ignition issues as well as providing multimeter and oscilloscope functions.

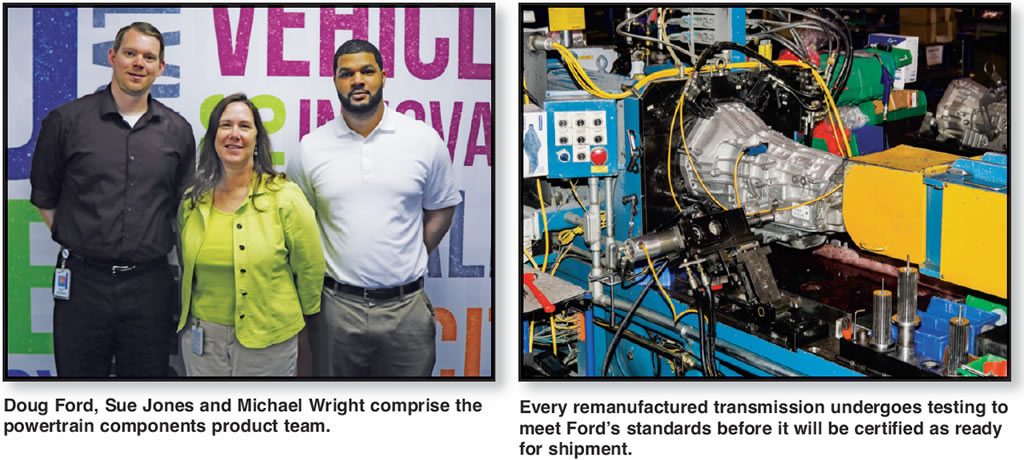

Fournier explains that independents are an important part of Ford’s planning and marketing. “Organizationally we’ve been making some changes in order to better serve customers. The North American Repair Product Planning team is a label that refers to a reorganized effort to address parts distribution and pricing for a number of categories. We are, in effect, product development for service parts.

“Sue Jones, in her marketing role as product manager, heads a team that includes a product planner and an engineer who work in concert to maintain components. Gregoricka heads a similar team with a planner and several engineers who are focused solely on remanufactured transmissions. The powertrain and collision teams I oversee are made up, including Sue and Dave’s teams of five of these product-planning teams.

“In addition to having the same focus, the engineers and product planners are now co-located, which promotes collaboration. Before we made this change the engineering group and the product-planning group were separate functions and were not co-located. The new structure allows for easier and more frequent communication between the people who together are working on various aspects of a particular line of Ford and Motorcraft products.”

Fournier says that the teams collect a lot of comparative data from aftermarket products that are available. “For instance,” she explains, “one of the things Sue’s team studies is various components in our line in comparison with aftermarket parts. That information relates to price and availability for each application and is incorporated into the marketing plan for those components to make sure that our Ford/Motorcraft products remain attractive and competitive in the eyes of our independent aftermarket customer.”

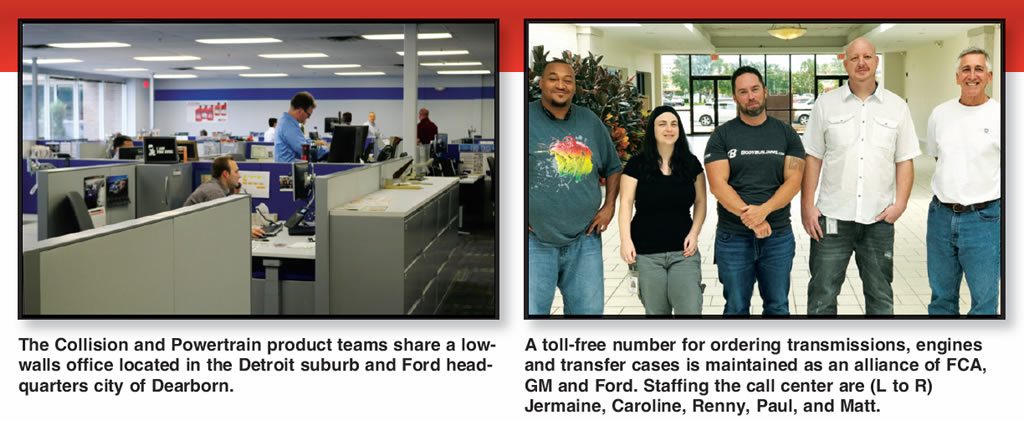

In addition to calling the local Ford dealership, transmission assemblies may be ordered from a toll-free number (800-392-7946) maintained collectively by Ford, GM and Fiat Chrysler. The call center staff has access to VIN and other information that is used to make sure that a transmission is the correct replacement for a given application.

Concluding, Fournier re-emphasizes, “We are working hard to be competitive; to be a supplier that an independent will turn to when a Ford or Lincoln vehicle job arrives in his shop.”