Up to Standards

- Subject: A different type of transmission

- Essential Reading: Rebuilder

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

Several weeks ago my partner Brian Johnston and I traveled to Chicago to visit ZF Industries’ North American headquarters in Vernon Hills, Ill. We have had a very long relationship with ZF as a distributor of its products. When Ford decided to stop offering a manual transmission in its full-sized pickup trucks, it caused a decline in our sales of ZF manual transmissions and of parts for the five- and six-speed series of transmissions.

Years ago ZF manufactured GM’s S6-40 six-speed transmission that was used in the 1989-96 Chevrolet Corvettes. ZF also provided remanufactured units for GM after new-car production went to Tremec. ZF awarded Rockland Standard Gear the remanufacturing contract for these S6-40 units and exclusive parts distribution to free up needed capacity in Vernon Hills for other projects.

The manual-transmission market has been declining steadily for a number of years, and we went to Chicago to discuss options available to us to carry more of the ZF line. ZF is widely known as an original-equipment manufacturer of manual and automatic transmissions and parts. However, the company is a worldwide conglomerate manufacturing many lines of original-equipment automotive parts and units used by auto, truck, marine, bus, construction and off-road equipment, helicopters etc.

Unknown to many of us ZF also has subsidiary companies that design, manufacture and supply a wide variety of parts to the world’s carmakers. Descriptions of these companies follow.

Sachs – This brand has OEM clutch kits, flywheels and hydraulics for the whole automotive market. Sachs also manufactures OEM ride-control products including shocks and struts, strut and spring assemblies, shock and strut mounts, the Nivomat ride-leveling suspension system, the CDC electronic damper systems, carbon-fiber struts and electronic ride-control systems.

Lemforder – supplier of OEM control arms, ball joints, tie-rod assemblies, bushings and stabilizer links.

Sachs Stabilus – global supplier of gas-charged lift supports for automotive use. This includes hood, hatch, trunk, glove-box, marine, RVs, truck caps, CV, off-highway vehicles, EZdown tailgate lowering kits and Powerise push-button automotive lift gates.

Hansen Transmission International – ZF acquired Hansen, a manufacturer of wind-turbine equipment for electric generation for utility companies worldwide. The service wing for this equipment is now at the ZF facility in Vernon Hills, Ill., and we were able to tour this area. The typical pictures one sees of wind-turbine generators are always from a distance, so it is very difficult to understand the size and scope of these machines.

A wind-turbine generator’s blade assembly has a diameter of 100 to 140 meters (300 to 459 feet). This is a lot longer than a football field, and to properly get the picture, the Airbus A380 passenger jet has a wingspan of 80 meters (262 feet). The turbine blades drive an electric generator through a planetary-type transmission, which increase the shaft speed at the generator to roughly 1,800 rpm. The generator, depending on size, can generate between 1,500 and 6,000 kilowatts of electricity. The rotor-shaft torque at the generator can be 500-3,500 KNm (thousand Newton meters), and the transmission – again, depending on kilowatt demand – can weigh 15,000 to 85,000 kilograms 33,000 to 187,000 pounds).

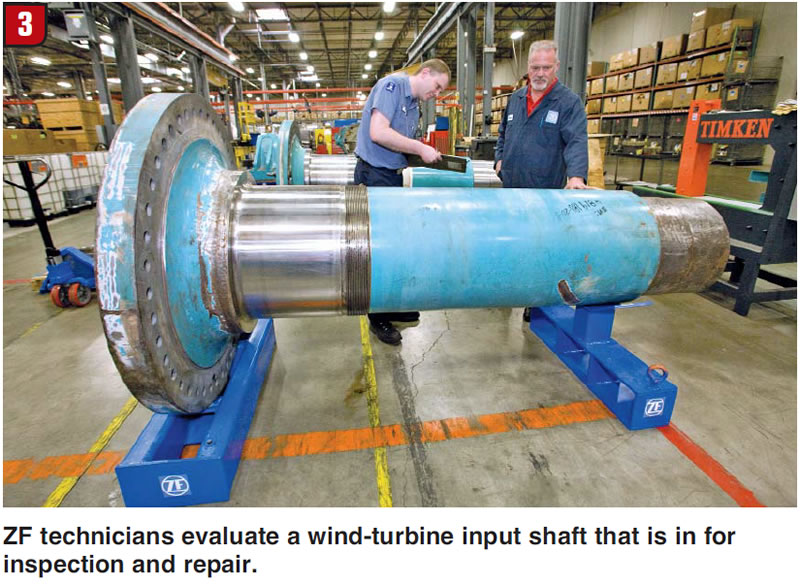

In Figure 1 you see a planetary that weighs 15,000 pounds being removed from a transmission. The nacelle that surrounds the transmission, generator and controls sits on a tower that is usually 150 meters (492 feet) above the ground and can rotate 360° to optimize wind power, or shut the system down in excessively high winds such as storms. The transmission uses a single planet with dual helical gearing to boost the shaft ratio to about 78-1 at the generator, increasing the generator speed to 1,800 rpm. There are no controls on the transmission; it operates as a single-speed unit driving the shaft through the planetary set.

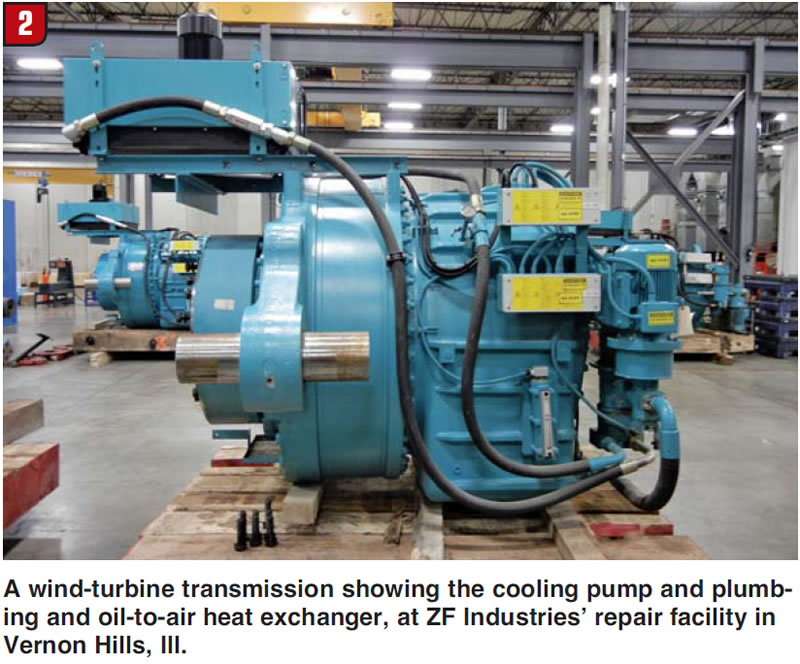

The transmission is cooled by 300 liters of oil through both forced and splash lubrication, with the oil then pumped through an oil-to-air heat exchanger that can cool the oil, or preheat it during cold-weather operation. This oil is an ISO 320 product equipped with extreme-pressure additives, and the average lube fill costs about $4,000-5,000. The gearbox cost is dependent on size, running from $150,000 to $1 million or more. The average R&R on one of the units runs about $150,000, and you won’t find that in a labor-and-time guide.

These wind turbines are operated from an offsite control room with remote monitoring of barometric pressure, ambient air temperature and wind speed, with computer controls that maximize the blade performance by changing pitch on the basis of desired energy output, speed and internal operating temperature. The blades can be feathered to flat, and the complete nacelle rotated, to stop operation whenever generation output exceeds the grid capacity or wind speeds are too high.

The Hansen International Division of ZF has manufacturing plants in the USA, China, Belgium and India, with Vernon Hills handling the service and repair work. The plants heat-treat and grind gears on a DIN quality scale of 4-5 and machine all these very large castings. They are capable of manufacturing external gears up to 1,700 mm (5.6 feet) and ring gears up to 2,800 mm (more than 9 feet) in diameter.

For us guys who have been holding planetaries in our hands for routine inspection most of our working lives, it was amazing to see a planet that weighs more than a car. The technicians who work in our industry are by nature gear heads and are fascinated by machinery of all kinds. This is truly the granddaddy of transmissions.