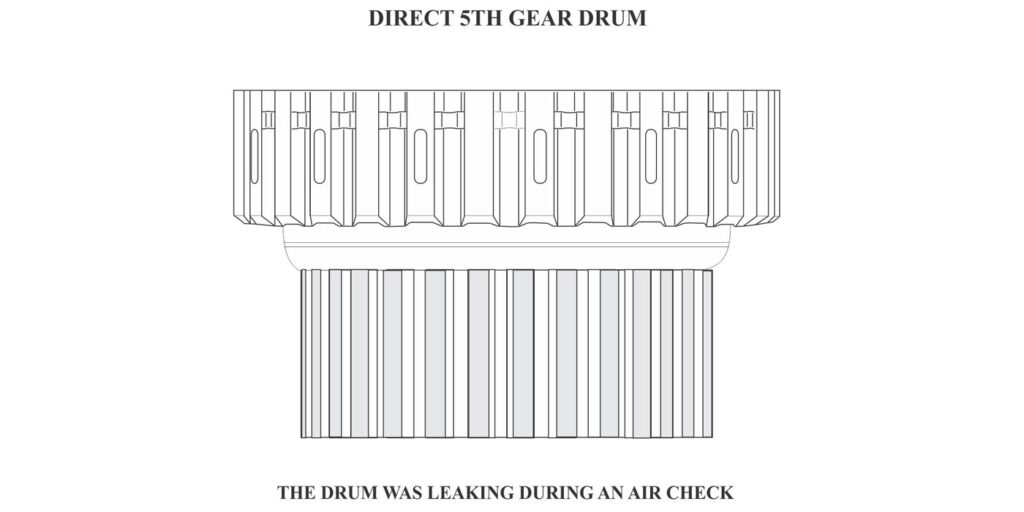

The Complaint

When rebuilding a Ford 6R60 or 6R80 transmission, the builder is confused by some published material which may show rebuild procedures on one but not the other. The confusion happens when rebuilding the direct drum due to this conflicting information.

The Cause

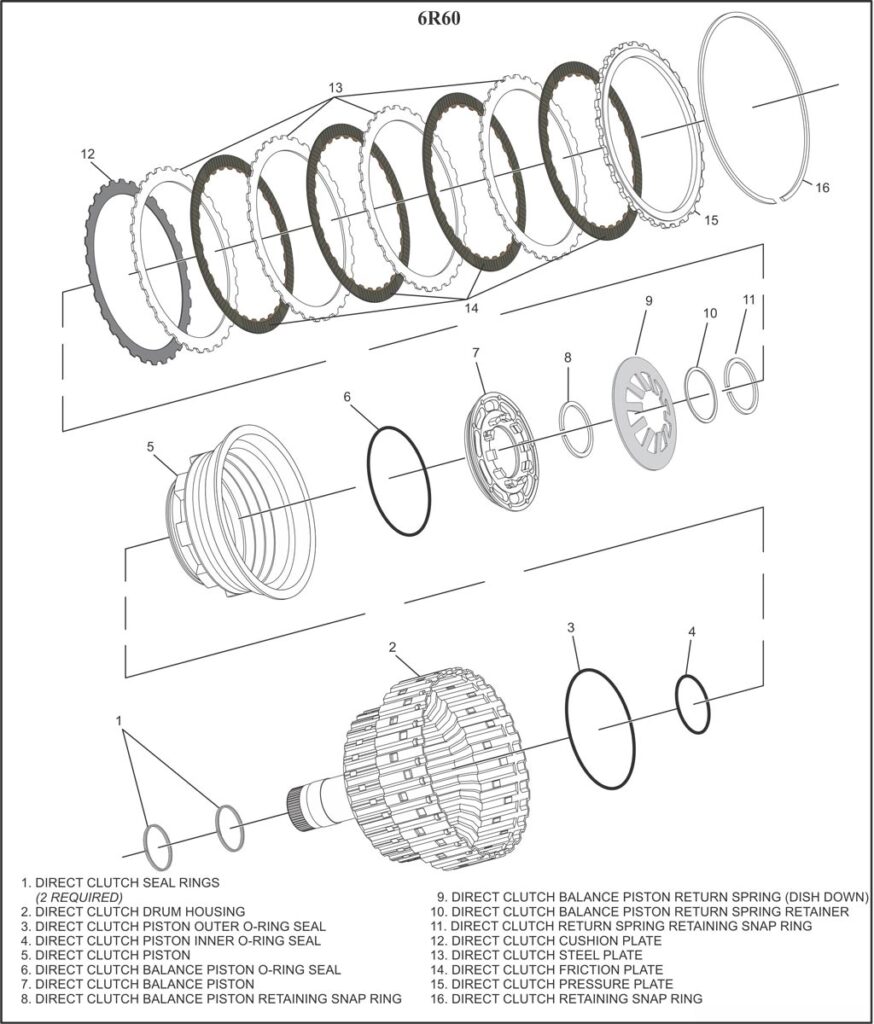

The 6R60 direct drum is assembled differently than the 6R80 drum. The 6R60 direct drum shown in figure 1 (above) has the apply piston going into the drum first, then the balance piston goes on top of the apply piston followed by a retaining snap ring. Then the direct clutch piston return spring is installed “dish down” as shown in figure 2 (below). Next goes a retaining ring, followed by the direct clutch piston return spring retaining snap ring.

The Correction

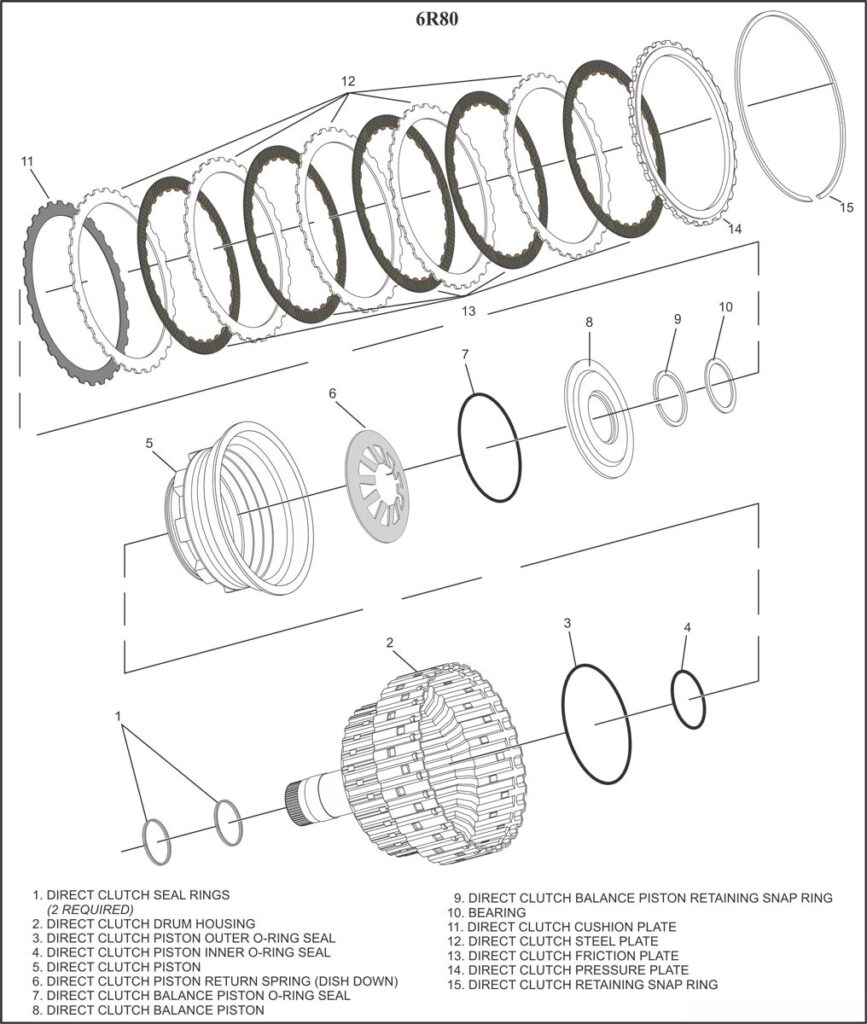

The 6R80 direct drum assembly also has the apply piston going into the drum first. This is followed by the apply piston return spring “dish down” as shown in figure 8. Next the balance piston is installed followed by the piston assembly retaining snap ring.

Consult the following two images depending on which of these transmissions you are rebuilding to remove the possibility of incorrect assembly due to other incomplete technical material.

Figure 2 Legend

- Direct clutch seal rings (2 required)

- Direct clutch drum housing

- Direct clutch piston outer o-ring seal

- Direct clutch piston inner o-ring seal

- Direct clutch piston

- Direct clutch balance piston o-ring seal

- Direct clutch balance piston

- Direct clutch balance piston retaining snap ring

- Direct clutch balance piston return spring (dish down)

- Direct clutch balance piston return spring retainer

- Direct clutch return spring retaining snap ring

- Direct clutch cushion plate

- Direct clutch steel plate

- Direct clutch friction plate

- Direct clutch pressure plate

- Direct clutch retaining snap ring

Figure 3 legend

- Direct clutch seal rings (2 required)

- Direct clutch drum housing

- Direct clutch piston outer o-ring seal

- Direct clutch piston inner o-ring seal

- Direct clutch piston

- Direct clutch piston return spring (dish down)

- Direct clutch balance piston o-ring seal

- Direct clutch balance piston

- Direct clutch balance piston retaining snap ring

- Bearing

- Direct clutch cushion plate

- Direct clutch steel plate

- Direct clutch friction plate

- Direct clutch pressure plate

- Direct clutch retaining snap ring