Ed’s Transmissions has been around in one form or another in Washington state since 1952, but the original owner Dick Matson has long since sold them to separate owners of his three locations. With the original store in Everett, Washington, and two other shops added later, the Marysville store is now embarking on an ownership change in the coming weeks.

Manager Andrew Koutlas (pronounced like the car, Cutlass) is in the process of purchasing Ed’s. He has been working there since 1998 when he started as a 16-year-old high school kid sweeping up and doing teardowns for the outgoing owners Ray and Lisa Phillips. The Marysville, Washington location, opened in 1982, has continually grown due to its proximity to Seattle (about 30-40 minutes north of the city).

“It was my first job, doing cleanup, and then it progressed from there to tearing down cores and cleaning the parts washer,” says Koutlas. “I then transitioned to R&R and pulling trannies; I did that for about five years before making the jump to the bench. I got really good at that, but then moved into the manager position while still building 3-4 transmissions per week.”

According to Koutlas, he decided to purchase the shop because the current owners wanted to get out and he has been running it for several years. “Our other manager is still rebuilding, but he got really burned out, so I was back managing after that. I think it’s been almost seven years now.”

Koutlas, who is 38, says he didn’t expect to be doing this as a career. But things kept falling into place for him. “The more experience I got, the more confidence I had. Our shop has treated me pretty well over the years. I’ve had some second jobs and a side business, but I just hit the point where I’m just going to go for it.”

It’s a tough industry, admits Koutlas. He says most of the guys he works with started like him as cleanup kids. “A lot of them are now getting closer to retiring. I feel like it’s a dying industry because there aren’t many young guys getting into it – around here anyway.”

And that is understandable since Seattle is home to Boeing and Amazon. “The kids today want to make $25-$30 an hour with no experience, and I get it. I started at $5.15 an hour, and I was simply happy to earn some money. I’m only 38, and one of the youngest guys around doing this in our area.”

Koutlas says they have a cast-iron power glide currently in the shop, but he is more familiar with the newer units. “I don’t know that stuff as much as like I’d like, because I grew up with mostly imports and the new six-speed stuff. We’re all really good at that. But we have a big enough crew where everyone has their niche.”

The year has been one of the shop’s busiest yet. They build cores for stock reman units for the retail side and wholesale customers. “I was building two to three units a week and now I’m like four to five units a week. And as I’m stepping into ownership, I’m coming in on the weekend and getting a few more done. We have about 120 stock units, but 10 years ago it was double that. We can’t replenish the stock units fast enough because we’re so busy.”

Koutlas says they are like a small Jasper because they rebuild so many cores for stock. They don’t buy any reman units; it’s all in-house rebuilds, as it has been since the beginning. “We build everything here. We don’t buy from anybody. We’re kind of a smaller size Jasper I guess.”

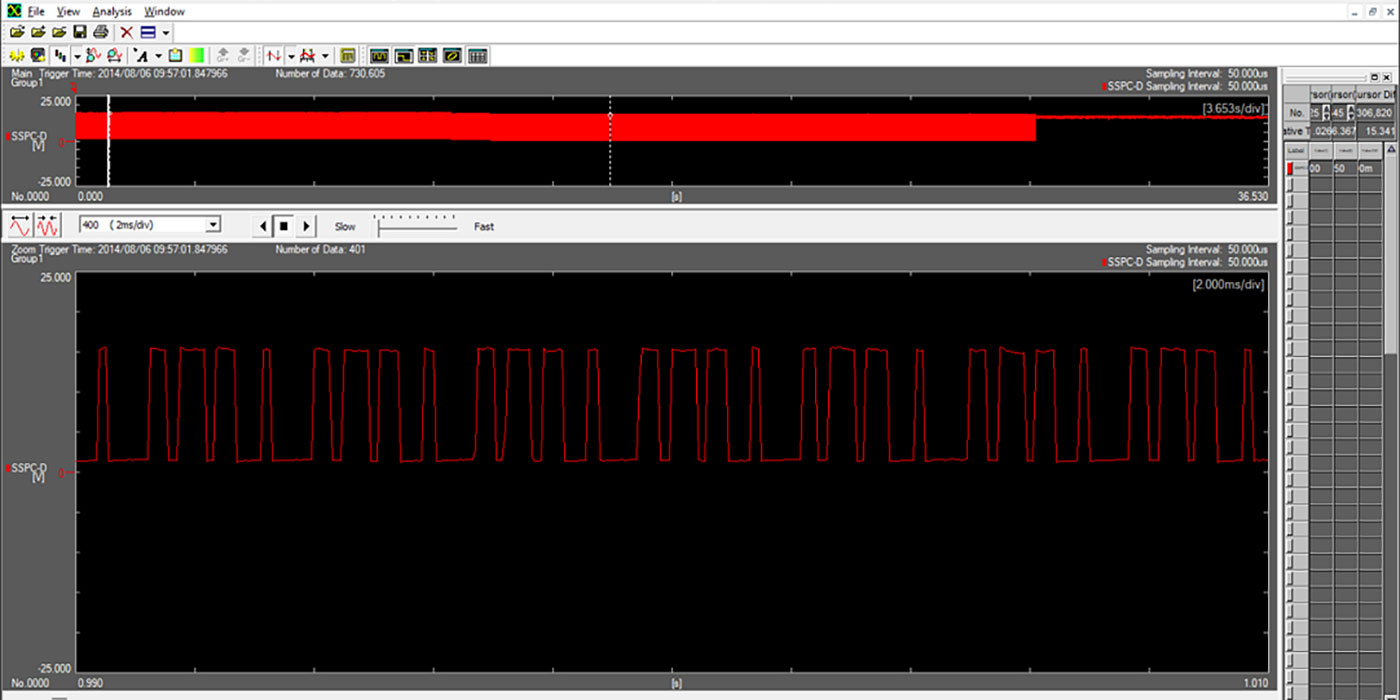

Ed’s Transmissions Marysville has four full-time builders and eight employees, including two delivery drivers. They even have a dyno that is run by one of their veteran builders, Louie. Koutlas says the dyno is for older units (pre-TECHM), but they put it to good use. “We catch 90% of the problems. It doesn’t put a full load on it. But sometimes we can chase a ghost with it. We’re pretty good with the older stuff – four-speeds, three-speeds and it still catches issues. I think it’s beneficial because we are about 60% retail and 40% wholesale. So we do a lot of units for other shops in the area. We can make sure it works and shifts before it leaves, but we can’t dyno the newest stuff.”

Koutlas says their delivery drivers help with the wholesale customers as far away as Eastern Washington. “If we have a shelf unit, we can bring them that and grab their core. We probably have 500 cores, but the things that are one-off, they pull it out, we’ll pick it up, build it and then deliver it.”

What sets Ed’s is that they are essentially a small remanufacturer and many of the shops in the area know they are fair and do good work “We have fair pricing compared to many others. And we’ve got 120 years-plus of experience here between all the guys. We’re lucky that we have really good technicians. They’re good guys. They have good attitudes, and they’re reasonable on the parts we use. We really have a good crew and a good location, which helps.”