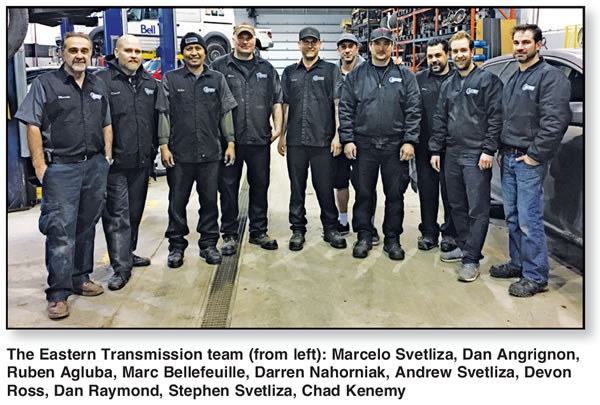

Eastern Transmission, St. Laurent, Quebec

Two brothers in their 30s are pushing forward with initiatives designed to build on their father’s success by virtue of a commitment to quality.

Recently, Eastern Transmission of has assembled specialty kits to compete with scrap yards and has taken on specialty repairs to develop new areas of expertise. Moreover, the business has become a distributor of Raybestos Powertrain parts, adding value not only as a separate venture but also as a user of the company’s products, said Stephen Svetliza, who spoke for his brother Andrew and father Marcelo. The shop is in St. Laurent, Quebec, a suburb of Montreal.

While the biggest change at Eastern is the distributorship, they have been working on their own specialty kits for sale across Canada and somewhat in the United States. The project started in house to offer an alternative to scrap parts for certain applications that are very expensive from the scrap yard, such as BMW differentials, he said.

At the same time, Eastern has a policy calling for a comprehensive rebuild of all components of all transmissions. “My biggest competition here is not the transmission shop that is a few miles away, but it’s the scrap yards that sell transmissions and differentials for prices that you cannot possibly compete with,” Stephen said.

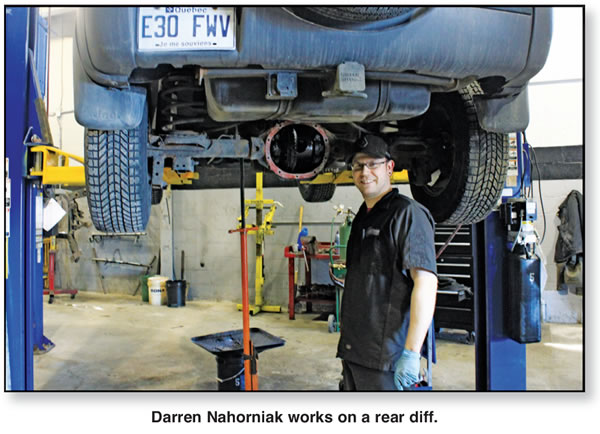

On another front, specialty repairs have been in demand.

“We’d never shy away from a job even if that job ultimately costs us money because we spent more time on it than expected,” Stephen said. “The hours that you spend the very first time you’re working on something pays dividends once you understand how it works and for the following cars that have the same problems. Now, all of a sudden you’ve created a new market for yourself.”

Roughly 20% of Eastern’s revenue comes from transmissions shipped to customers as far as British Columbia. To minimize problems at the customer’s end, the shop tests rebuilt units on a dynamometer. It’s also used for in-house testing before delivering the vehicle to the customer. At the beginning of the repair process, diagnosis and road test is free; further exploration requires the customer to commit to a charge for an hour or two as needed.

With this commitment to quality including full rebuild of transmissions, Stephen said he has no concerns about their 3-year, 80,000 km warranty (nearly 50,000 miles); what’s more, the warranty is not the issue.

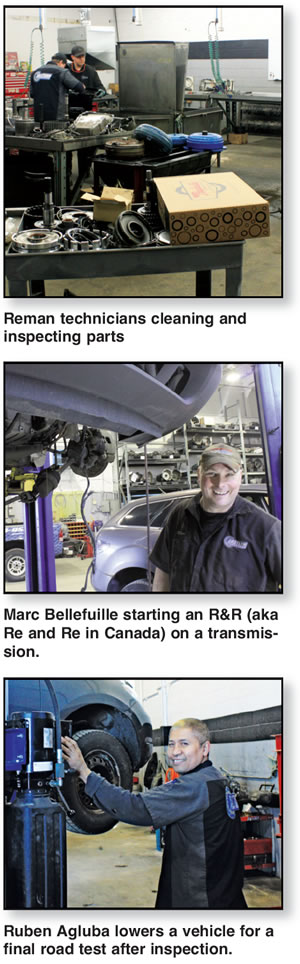

“Every rebuild that we do comes standard with an overhaul, a friction kit, a bushing kit, a piston kit, all the bands, a filter and a complete rebuild of the valve body,” he said. “We’re going to charge a little more for the job because we’re investing more into them, and in a market where people will jump to the competitor for a $50 difference in price, without understanding what goes into their transmissions, we decided, if you build them properly, they should last a heck of a lot longer than three years.”

History & operations

Twenty years ago, Marcelo bought the existing Eastern Transmission, which dates to 1989. Andrew came on board in 2005, Stephen in 2012, when the shop moved to a facility with triple the space. Marcelo still works but has put his sons in charge. Andrew and Stephen do not have transmission training but rely on nine people who Stephen describes as “a fantastic team of technicians.”

The three Svetlizas fill the remaining duties. Andrew manages the Raybestos Powertrain distributorship and Stephen handles customer relations and business functions.

Stephen sums up the operation: “lean but efficient.”

The business casts a wide net across eastern Canada, with motorists driving three or four hours from northern Quebec. One of their biggest customers is from Newfoundland, and units are shipped nationwide. Their largest source of business comprises five of the biggest extended-warranty companies in Quebec. A major fleet customer is a large telecommunications company.

The shop has eight bays with seven lifts and one rack. The shop completes 5-10 transmission jobs per week. The shop is equipped for most vehicles except for large trucks such as 18-wheelers.

Distributorship

The relationship with Raybestos Powertrain took shape near the end of 2016, Stephen said.

“This venture and this product that we’re offering – they are premium rebuild kits that Raybestos offers: the best of the best products in your everyday rebuild kits. It’s a big challenge for us in our business,” he said.

“These kits pertain to everybody out there, whereas some of the other specialty products pertain to certain people. We have been able to create a network globally at this point. Our main focus has been the United States and Canada. This has opened a lot of doors to a lot of fantastic places south of the border for us and even on our end of the border. … With the addition of this network, we can now source into the U.S. many products at better prices than we can here in Canada.”

Meanwhile, Eastern is using Raybestos Powertrain kits in its own work, boosting quality and efficiency while reducing costs.

“Ordering takes a fraction of the time. The builders build faster because they are given all the components in one box,” Stephen said, adding that there’s no more waiting for parts, no receiving wrong parts. This streamlining of the process meshes with the Svetlizas’ goal of creating a standard for transmission rebuilding, doing it the Eastern way.

Overall, the arrangement has been successful all around, Stephen said.

“With this network, the main thing, we’ve created a lot of new friends and new contacts and lot of people to help each other out.”