Only One Way – the Right Way

Those of you who read my articles know that from time to time I may bore you with gear-train operation. It’s a part of the transmission’s operation that has always fascinated me. Understanding it goes a long way toward diagnosing various complaints, especially those involving noise.

In this instance I’m going to talk about a one-way-clutch device in a 62TE transmission (figures 1 & 2). But I first need to go through my boring explanation of the “foot bone being connected to the ankle bone” type details of the underdrive centerline shaft known as the underdrive compounder assembly (Figure 3).

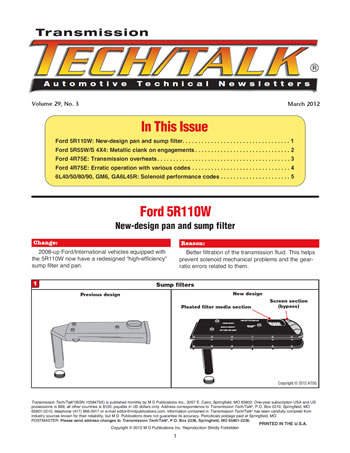

March 2012 Issue

In This Issue

Ford 5R110W: New-design pan and sump filter

Ford 5R55W/S 4X4: Metallic clank on engagements

Ford 4R75E: Transmission overheats

Ford 4R75E: Erratic operation with various codes

6L40/50/80/90, GM6, GA6L45R: Solenoid performance codes

Alignment

No, not wheel alignment – people alignment; aligning yourself with the right people for the situation you happen to find yourself in at any given time.

All the books we’ve read and audio programs we’ve listened to about goal setting and achievement tell us that after we decide on what we want and set a goal we have to make and stick to a plan. Part of that plan has to be identifying and aligning ourselves with people in the right places who can help us get what we need.

Humming Along with the BorgWarner 4493/4494 Transfer Case

GM had great sales for a time with the Hummer brand. The economy has foreclosed on that segment of the market, and GM has sold the brand to a Chinese company. However, there are lots of Hummer H3s around and no dealer body to repair them, which sounds like opportunity for the transmission shop.

The Hummer H3 was available with either an automatic or manual transmission and used a 4493/4494 transfer case manufactured by BorgWarner. The 4493 and 4494 are operationally the same transfer case, a three-position, electrically shifted unit. The 4493 has a 2.64 low-gear ratio and the 4494 has a 4.1 low-gear ratio, which makes it a good rock crawler for the off-road guys. This obviously means that the internal gear trains will be different.

Quit Dimpling Those Converters

This all started with my looking at multiple converter failures caused by the converter bolts damaging the backs on Toyota A245E/A246E transmissions used with the 1.8-liter engine. We also see this in other Toyota applications, maybe more so than with other vehicle manufacturers.

My intentions were to order some factory bolts to get the proper dimensions and possibly send these reman units out with new bolts, either OE or an economical replacement bolt. I was hoping this would eliminate any confusion for the R&R technician as to which bolts were the proper ones to go into the converter, hence eliminating unwanted warranty repairs.

Clearing up Some Toyota Solenoid Confusion

Different terminology for the same part has been an ongoing problem in the transmission industry ever since I can remember. When I was learning to rebuild transmissions, Chrysler Torqueflite and Ford C-4 transmissions were always in the shop. These two transmissions had the same power flow, but all the internal components had different names.

Upgrading the Honda Impeller-to-Stator Bearing

Torque-converter rebuilders have been reporting Honda bearing failures in increasing numbers. The bearing failures have been from different locations within the converters and have been reported in most of the Honda and Acura models. The most common of the failures has been the bearing between the impeller and stator in the larger-diameter converters. In all converters, the bearing in this location carries most of the thrust load when the vehicle is accelerating, and it is typically the first bearing to fail. Because the larger-diameter converters are used in the larger, higher-torque V-6 applications, the thrust loads on this bearing are even greater.

Fine-Tuning the NVG 247 Transfer Case

The New Venture 247 transfer case was used in the Jeep Grand Cherokee (WJ) vehicle in the 1999 to 2004 model years. Nobody throws away a Jeep, and these units create a lot of repair work and parts sales. They also generate an inordinate amount of tech calls as a result of the problems with the design and misunderstood theory of operation. This article will concentrate on the areas that cause shops the most trouble in diagnosis and repair.

Taking it to the Track, Part II: Our Charger Runs the Quarter Mile

In my previous installment (November 2011), I profiled our progress of “hot-rodding” a part-time sheriff’s car for our local one-fourth-mile drag strip, Bandimere Speedway.

Our speedway hosts a program called “Take it to the Track,” an initiative aimed at getting young drag racers off the street and onto a safer venue, and this 2006 Dodge Charger just needed its exhaust system installed before we could start the engine.

It’s Sometimes Overwhelming

Are you in a continual state of being overwhelmed by either having so many customers that you can’t find adequate time to sell properly and do for them everything they need, or not having enough customers and always being behind with the bills you have and sometimes cannot pay? Either scenario is not healthy for you or your business. In fact, the first could easily lead to the second if not remedied. Not spending enough time with your good customers and selling them what they really need when they come in for minor services can lose many of them for you and put you in the unenviable position of not having enough customers to generate the dollars you need.

A Hard Shift Fixed by a Gentle Squeeze

The RE4F03/4B transmission in several Nissan vehicles develops a hard 1-2 upshift as a result of uncontrolled line pressure. Sometimes code P0745 is stored for a problem in the line-pressure-control solenoid circuit. Replacing the solenoid assembly usually fixes the problem. But, the next time this happens to you, or you get to experience this for the first time, the fix may be as simple as gently squeezing a crimp.

Once More, Not the Transmission

It’s very simple to get steered in the wrong direction when you’re diagnosing a transmission complaint. There are so many different sensors and components that can cause transmission-like symptoms that at first it seems as if without a doubt you have a transmission problem, and from a customer’s perspective they are convinced it’s going to cost them an arm and a leg, which provides you the opportunity to be a hero and gain a customer for life.