Up to Standards

- Subject: Design and operation

- Unit: 4493/4494 transfer case

- Vehicle Application: GM Hummer H3

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

GM had great sales for a time with the Hummer brand. The economy has foreclosed on that segment of the market, and GM has sold the brand to a Chinese company. However, there are lots of Hummer H3s around and no dealer body to repair them, which sounds like opportunity for the transmission shop.

The Hummer H3 was available with either an automatic or manual transmission and used a 4493/4494 transfer case manufactured by BorgWarner. The 4493 and 4494 are operationally the same transfer case, a three-position, electrically shifted unit. The 4493 has a 2.64 low-gear ratio and the 4494 has a 4.1 low-gear ratio, which makes it a good rock crawler for the off-road guys. This obviously means that the internal gear trains will be different.

Both models have 4 HI four-wheel drive, which is full time and allows driving on dry pavement; and 4 HI Lock and 4 LO Lock, which are part-time modes for usage off road and on snow, dirt, sand and mud. These transfer cases have a planetary-type differential that provides a 40/60 torque split front to rear for full-time four-wheel drive. Full-time means that both prop shafts are being driven continuously, providing better traction in all conditions. When the transfer case is in either of the locked positions these vehicles should be driven only off road or in snow etc.

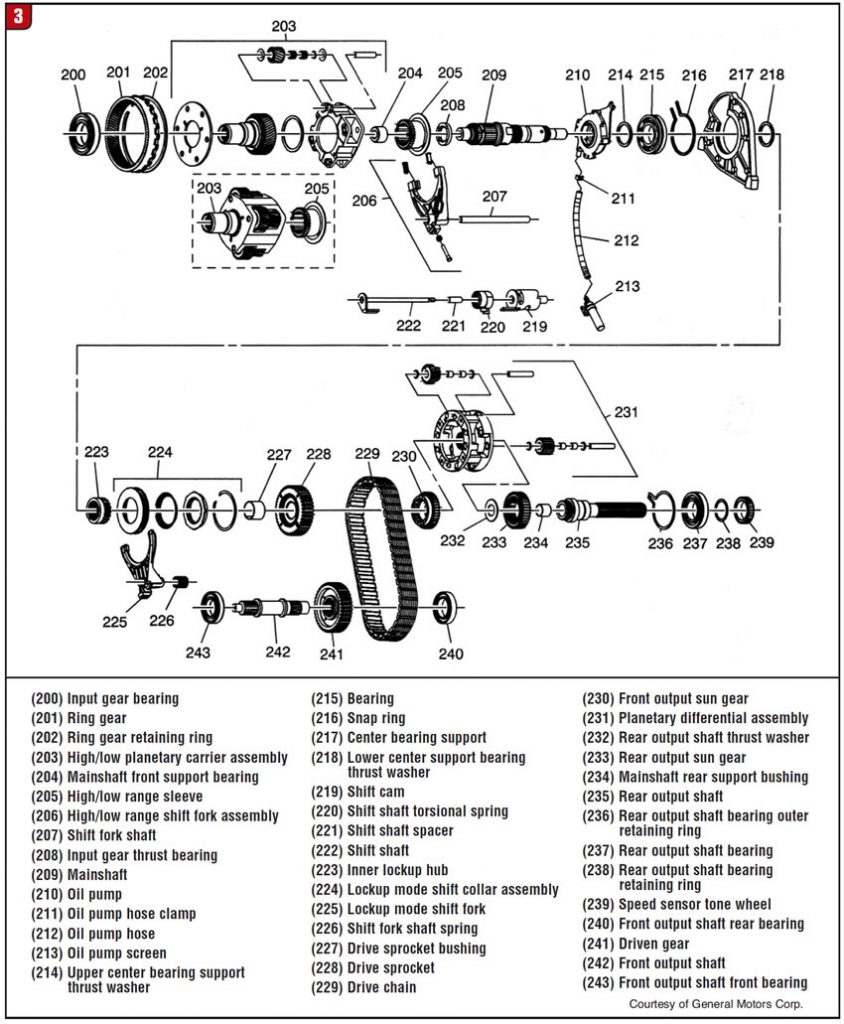

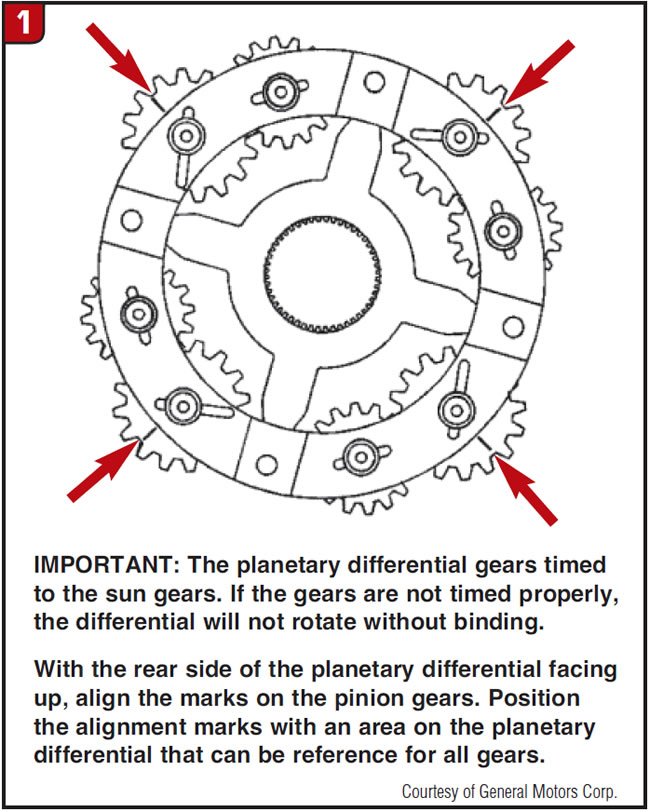

The planetary differential is a six-pinion unit with two different sun gears providing 40% torque to the front and 60% to the rear prop shaft. The gears in this planetary differential are timed and are equipped with timing marks that must be aligned as in Figure 1 to install the sun gears. Not paying attention to the timing marks will create hair loss and other thoughts of alcohol and drug abuse.

These units use magnesium cases, which means you need to make sure you use the original bolts to put them together, as magnesium and steel are always at war chemically. These units use Dexron III ATF for lube, with a capacity of 1.7 quarts. Lubrication internally is provided by splash and an integral oil pump providing pressurized oil to lube the shafts and gears. As with all computer-controlled transfer cases, tire circumference must be within 1/4 inch all around and tire pressures must be equal to prevent the computer from generating fault codes and to avoid various crow-hop and shudder drivability issues.

On the electronic side the vehicle is equipped with a computer (transfer-case control module), an electric encoder shift motor mounted on the transfer case, and multiple speed sensors to inform the computer of the various vehicle and axle speeds. The driver has access to a four-position dash-mounted shift-control switch. Selecting a position to choose a new mode or gear position starts the switch flashing to inform the driver that the shift-control module has received the request. When all shift criteria are met for the software to make the shift, and the encoder motor completes the shift, the light will change to a solid illumination until the next choice is made.

Many of these vehicles are equipped with an electric rear-differential lock that can be engaged only in the 4 LO Lock position with the vehicle speed under 20 mph. This option has created many wrong-diagnosis issues for shops when it malfunctions. If the rear differential stays locked on because of some damage or electric fault, it can falsely lead a shop to believe the problem is in the transfer case. These units also have a neutral position that can be achieved when the ignition is on, the automatic trans is in neutral, vehicle speed is 3 mph or less and the transfer case is in 4 Hi mode. Pressing the 4HI Lock and 4 LO Lock buttons simultaneously for 10 seconds will shift into neutral. The completed neutral shift will cause the red neutral button to light.

As with many other encoder motors there are four encoder channels, which the TCM monitors to confirm the position of the motor and gear or mode that the transfer case is in. These circuits are bidirectional and can be monitored or activated by the correct scan tool. It is vital to know that the transfer-case shift-control modules have multiple software programs for each variety of vehicle. You must input the VIN into the scan tools if you are changing modules so that the computer will use the correct software for the axle ratio, transmission, engine and tire size. This information will flow from the powertrain control module to the transfer-case control module through a class-2 data bus. The TCM also monitors wheel speed, vehicle speed and encoder-motor position through a class-2 data bus.

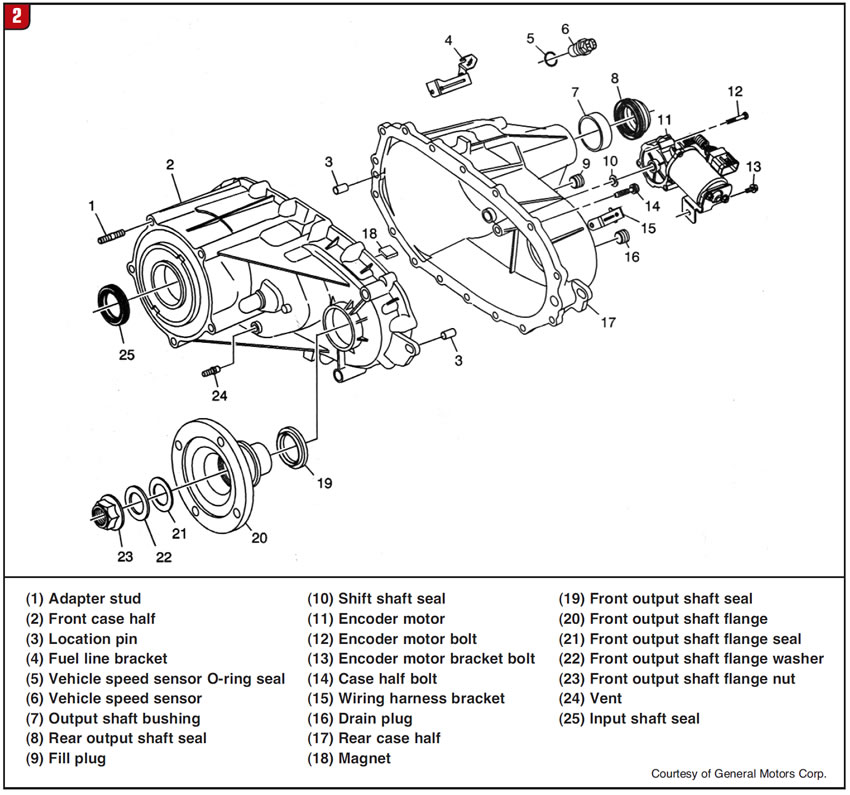

Figure 2 shows the case components, and Figure 3 shows internal components.